Popular Woodworking 2008-08 № 170, страница 12

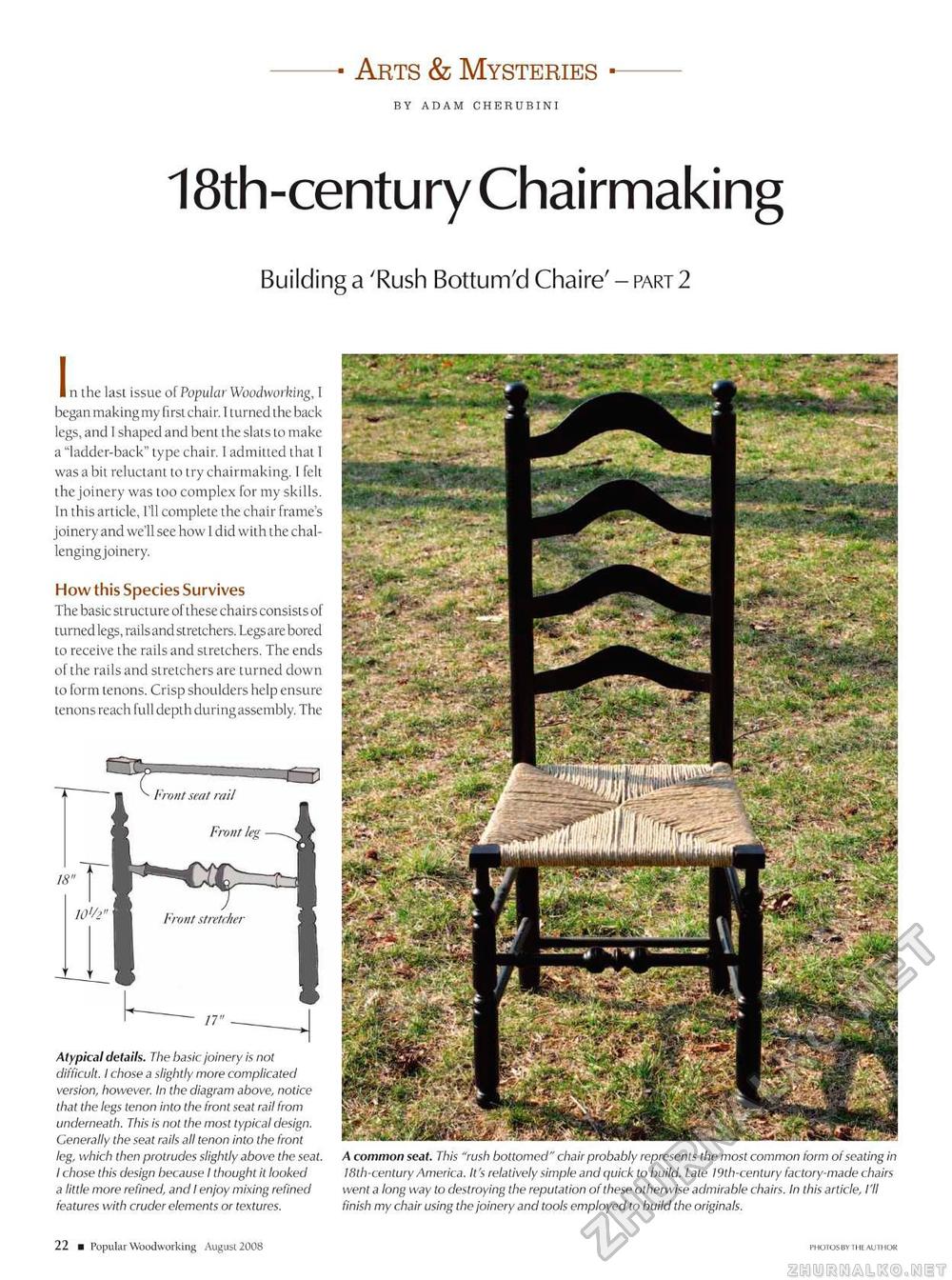

- Arts & Mysteries - BY ADAM CHERUBINI 18th-century Chairmaking Building a 'Rush Bottum'd Chaire' - part 2 n the last issue of Popular Woodworking, I began making my first chair. I turned the back legs, and I shaped and bent the slats to make a "ladder-back" type chair. T admitted that I was a bit reluctant to try chairmaking. 1 felt the joinery was too complex for my skills. In this article, I'll complete the chair frame's joinery and we'll see how 1 did with the chal-lengingjoinery. How this Species Survives The basic structure of these chairs consists of turned legs, rails and stretchers. Legs are bored to receive the rails and stretchers. The ends of the rails and stretchers are turned down to form tenons. Crisp shoulders help ensure tenons reach full depth during assembly. The Atypical details. The basic joinery is not difficult. I chose a slightly more complicated version, however. In the diagram above, notice that the legs tenon into the front seat rail from underneath. This is not the most typical design. Generally the seat rails all tenon into the front leg, which then protrudes slightly above the seat. I chose this design because I thought it looked a little more refined, and I enjoy mixing refined features with cruder elements or textures. A common seat. This "rush bottomed" chair probably represents the most common form of seating in 18th-century America. It's relatively simple and quick to build. Late 19th-century factory-made chairs went a long way to destroying the reputation of these otherwise admirable chairs. In this article, I'll finish my chair using the joinery and tools employed to build the originals. |