Popular Woodworking 2008-12 № 173, страница 46

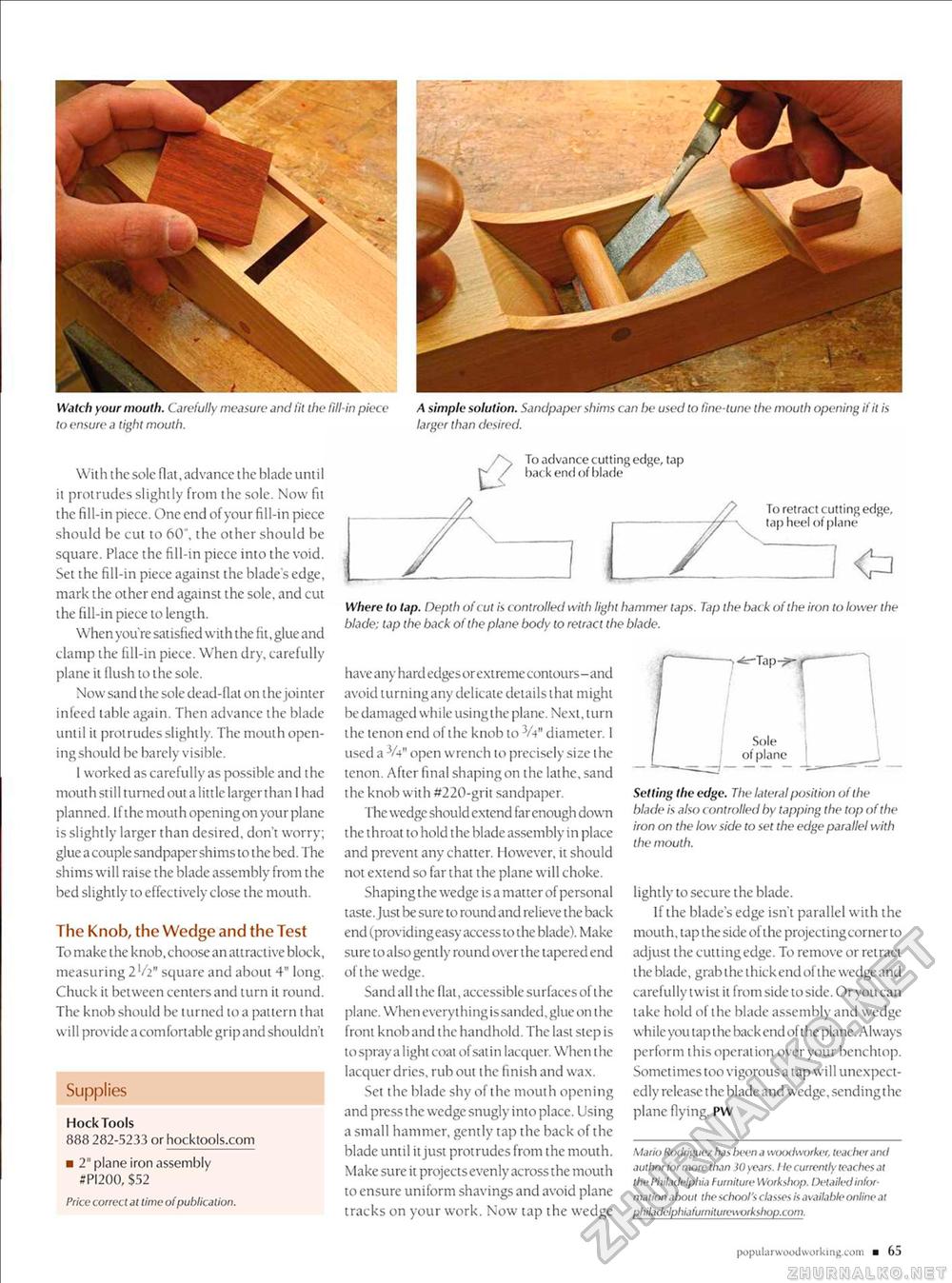

Watch your mouth. Carefully measure and fit the fill-in piece A simple solution. Sandpaper shims can he used to tine-tune the mouth opening if it is to ensure a tight mouth. larger than desired. popularwoodvvorking.com ■ 65 With the sole flat, advance the blade until it protrudes slightly from the sole. Now fit the fill-in piece. One end of your fill-in piece should be cut to 60°, the other should be square. Place the fill-in piece into the void. Set the fill-in piece against the blade's edge, mark the other end against the sole, and cut the fill-in piece to length. When you're satisfied with the fit, glue and clamp the fill-in piece. When dry, carefully plane it Hush to the sole. Now sand the sole dead-fiat on the jointer infeed table again. Then advance the blade until it protrudes slightly. The mouth opening should be barely visible. 1 worked as carefully as possible and the mouth still turned out a little largerthan I had planned. If the mouth opening on your plane is slightly larger than desired, don't worry; glue a couple sandpaper shims to the bed. The shims will raise the blade assembly from the bed slightly to effectively close the mouth. The Knob, the Wedge and the Test To make the knob, choose an attractive block, measuring 2 Vi" square and about 4" long. Chuck it between centers and turn it round. The knob should be turned lo a pattern that will provide a comfortable grip and shouldn't Supplies Hock Tools 888 282-5233 or hocktools.com ■ 2" plane iron assembly SPI200, $52 Price correct at time ol publication. A To advance cutting edge, r- / back end of blade XJ. Where to tap. Depth of cut is controlled with light hammer taps. Tap the back of the iron to lower the blade; tap the back of the plane body to retract the blade. have any hard edges orextreme contours-and avoid turningany delicate details that might be damaged while using the plane. Next, turn the tenon end of the knob to Vv diameter. 1 used a V4" open wrench to precisely size the tenon. After final shaping on the lathe, sand the knob with #220-grit sandpaper. The wedge should extend far enough down the throat to hold the blade assembly in place and prevent any chatter. However, it should not extend so far that the plane will choke. Shaping the wedge is a matter of personal taste. Just be sure to round and relieve ihe back end (providingeasy access to ihe blade). Make sure to also gently round over the tapered end of the wedge. Sand all ihe flat, accessible surfaces of the plane. When everything is sanded, glue on the front knob and ihe handhold. The last slep is to spray a light coat of sat in lacquer. When the lacquer dries, rub out the finish and wax. Set the blade shy of the mouth opening and press the wedge snugly into place. Using a small hammer, gently tap the back of the blade until it just protrudes from the mouth. Make sure it projects evenly across the mouth to ensure uniform shavings and avoid plane tracks on your work. Now tap the wedge Mario Rodriguez has been a woodworker, teat her anil author for more than JO years. I le currently teaches at the Philadelphia furniture Workshop. Detailed information about the school's classes is available online at philadclphiaiurnUureworkshop.com. Setting the edge. The lateral position of the blade is also controlled by tapping the top of the iron on the low side to set the edge parallel with the mouth. lightly to secure the blade. If the blade's edge isn't parallel with the moul h. t ap t he side of t he projecting corner 10 adjust the cutting edge. To remove or retract the blade, grab the thick end of the wedge and carefully twist it from side to side. Or you can take hold ol the blade assembly and wedge while you tap the back end of the plane. Always perform this operation over your benchlop. Sometimes too vigorous a tap will unexpectedly release t he blade and wedge, sending the plane flying. PW To retract cutting edge, tap heel of plane |