Popular Woodworking 2008-12 № 173, страница 48

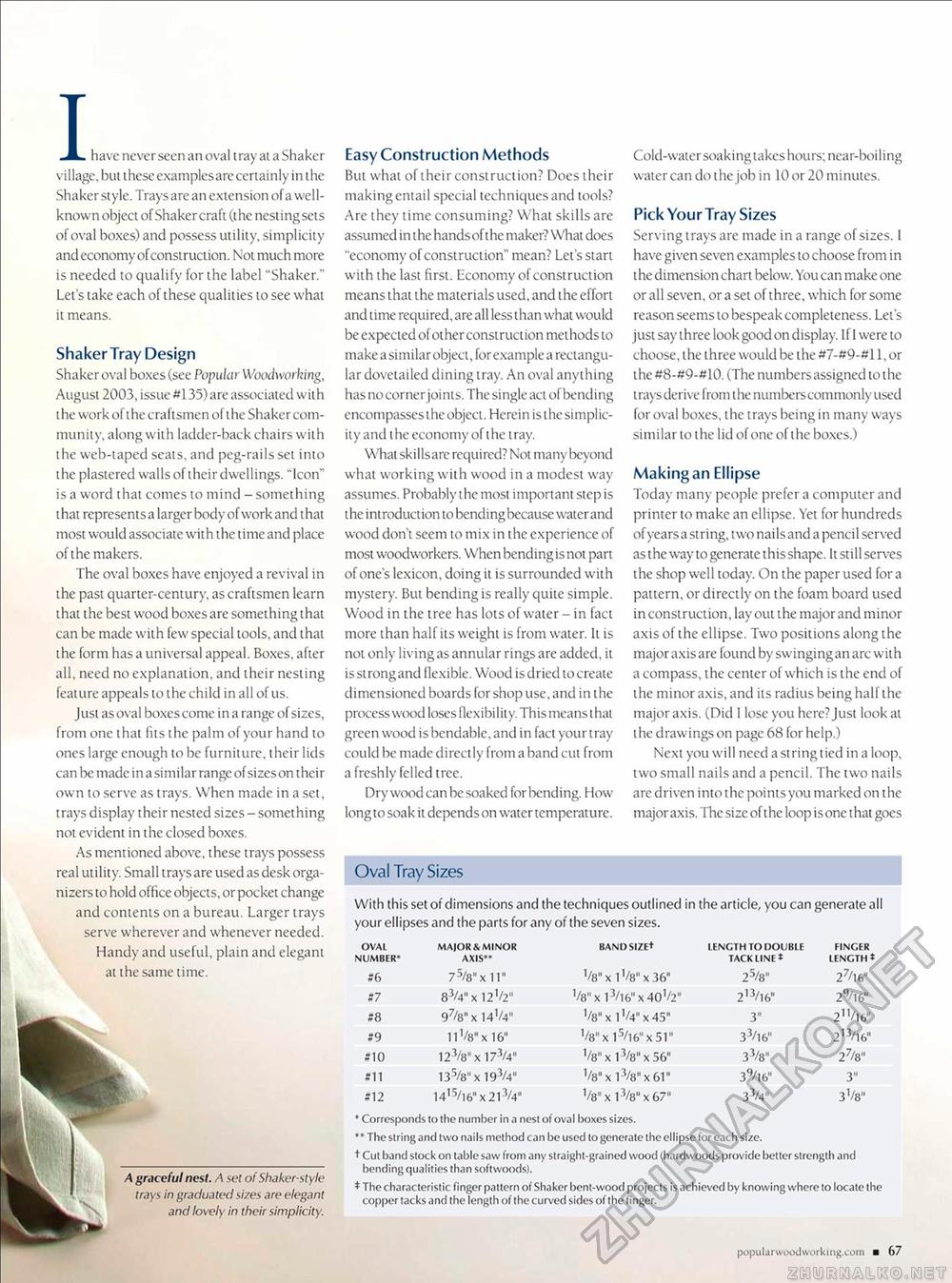

have never seen an oval tray at a Shaker village, but these exaraplesare certainly in the Shaker style. Traysare an extension of a well-known object of Shakercraft (the nesting sets of oval boxes) and possess utility, simplicity and economy of construction. Not much more is needed to qualify for the label "Shaker." Let's take each of these qualities to see what it means. Shaker Tray Design Shaker oval boxes (see Popular Woodworking, August 2003, issue#135) are associated with the work of the craftsmen of the Shaker community, along with ladder-back chairs with the web-taped seats, and peg-rails set into the plastered walls of their dwellings. "Icon" is a word that comes to mind - something that represents a larger body of work and that most would associate with the time and place of the makers. The oval boxes have enjoyed a revival in the past quarter-century, as craftsmen learn that the best wood boxes are something that can be made with few special tools, and that the form has a universal appeal. Boxes, after all, need no explanation, and their nesting feature appeals to the child in all of us. Just as oval boxes come in a range of sizes, from one that fits the palm of your hand to ones large enough to be furniture, their lids can be made in a similar range of sizcson their own to serve as trays. When made in a set, trays display their nested sizes - something not evident in the closed boxes. As mentioned above, these trays possess real utility. Small traysare used as desk organizers to hold office objects, or pocket change and contents on a bureau. Larger trays serve wherever and whenever needed. Handy and useful, plain and elegant at the same time. Easy Construction Methods But what of their construction? Does their making entail special techniques and tools? Are they time consuming? What skills are assumed in the hands of the maker? What does "economy of construction" mean? Let's start with the last first. Economy of construction means that the materials used, and the effort and time required, are all less than what would be expected of other construction methods to make a similar object, for example a rectangular dovetailed dining tray. An oval anything has no corner joints. The single act of bending encompasses the object. Herein isthe simplicity and the economy of the tray. What skillsare required? Not many beyond what working with wood in a modest way assumes. Probably the most important step is the introduction to bending because water and wood don't seem to mix in the experience of most woodworkers. When bending is not part of one's lexicon, doing it is surrounded with mystery. But bending is really quite simple. Wood in the tree has lots of water - in fact more than half its weight is from water. It is not only living as annular rings are added, it is strong and flexible. Wood is dried to create dimensioned boards for shop use, and in the process wood loses flexibility. This means t hat green wood is bendable, and in fact your tray could be made directly from a band cut from a freshly felled tree. Dry wood can be soaked for bending. How long to soak it depends on water temperature. Cold-water soaking takes hours; near-boiling water can do the job in 10 or 20 minutes. Pick Your Tray Sizes Serving trays are made in a range of sizes. I have given seven examples to choose from in the dimension chart below. You can make one or all seven, or a set of three, which for some reason seems to bespeak completeness. Let's just say three look good on display. Iff were to choose, the three would be the #7-#9-#l 1, or the #8-#9-#10. (The numbers assigned to the trays derive from the numbers commonly used for oval boxes, the trays being in many ways similar to the lid of one of the boxes.) Making an Ellipse Today many people prefer a computer and printer to make an ellipse. Yet for hundreds of years a string, two nails and a pencil served as the way to generate this shape. It still serves the shop well today. On the paper used for a pattern, or directly on the foam board used in construction, lay out the major and minor axis of the ellipse. Two positions along the major axis are found by swinging an arc with a compass, the center of which is the end of the minor axis, and its radius being half the major axis. (Did 1 lose you here? Just look at the drawings on page 68 for help.) Next you will need a string tied in a loop, two small nails and a pencil. The two nails are driven into the points you marked on the major axis. The size of the loop is one that goes Oval Tray Sizes With this set of dimensions and the techniques outlined in the article, you can generate all your ellipses and the parts for any of the seven sizes.

* Corresponds to the number in a nest of oval boxes sizes. * * The string and two nails method can be used to generate the ellipse for each size. * Corresponds to the number in a nest of oval boxes sizes. * * The string and two nails method can be used to generate the ellipse for each size. + Cut band stock on tabic saw from any straight-grained wood (hardwoods provide better strength and bending qualities than softwoods). * The characteristic finger pattern of Shaker bent-wood projects is achieved by knowing where to locate the copper tacks and the length of the curved sides of the finger. popularwoodvvorking.com ■ 67 A graceful nest. A set of Shaker-style trays in graduated sizes are elegant and lovely in their simplicity. |