38 - Ring Boxes, страница 10

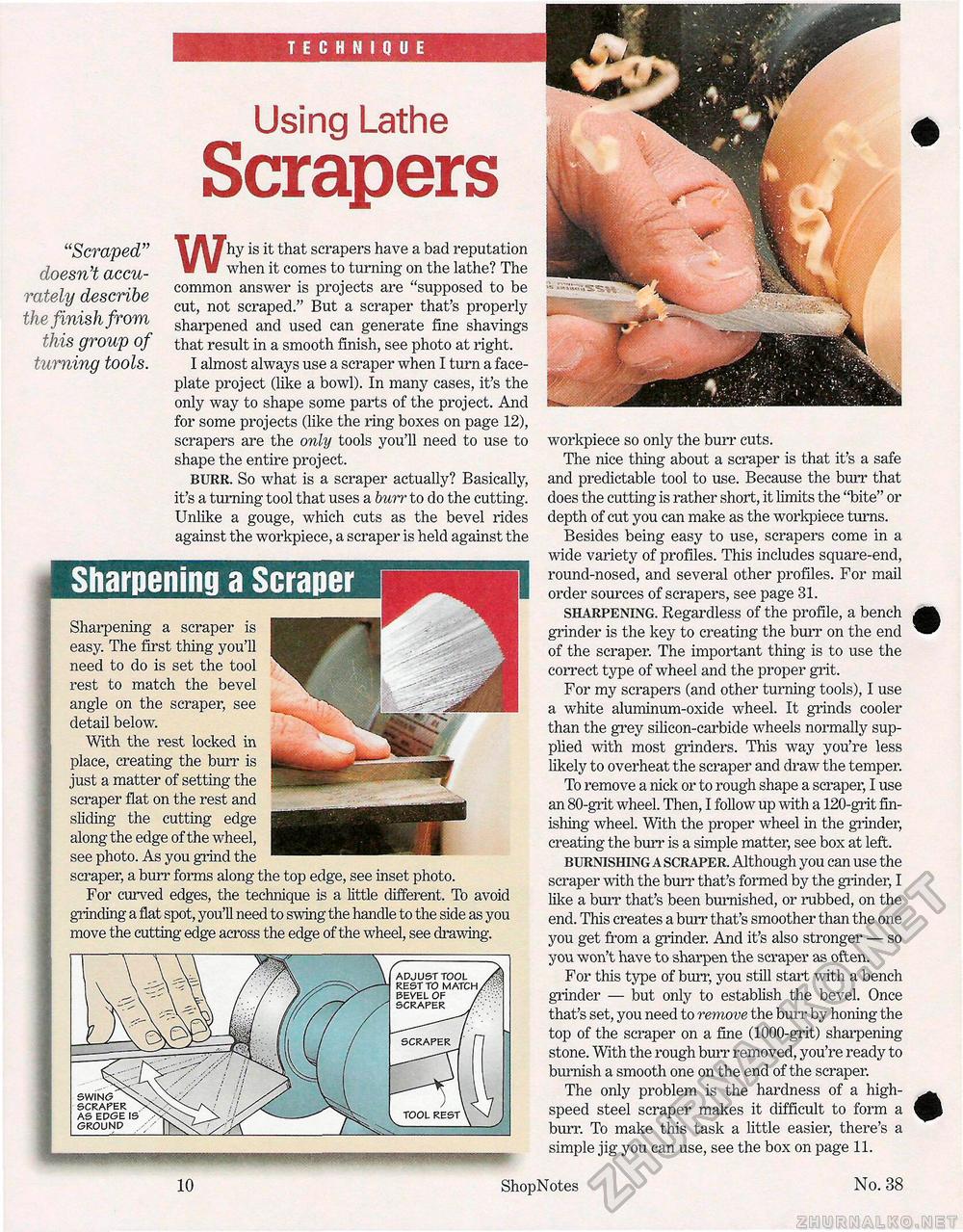

"Scraped" doesn't accurately describe the finish from this group of turning tools. Using Lathe ScrapersWhy is it that scrapers have a bad reputation when it comes to turning on the lathe? The common answer is projects are "supposed to be cut, not scraped." But a scraper that's properly sharpened and used can generate fine shavings that result in a smooth finish, see photo at right. I almost always use a scraper when I turn a faceplate project (like a bowl). In many cases, it's the only way to shape some parts of the project. And for some projects (like the ring boxes on page 12), scrapers are the only tools you'll need to use to shape the entire project. burr. So what is a scraper actually? Basically, it's a turning tool that uses a burr to do the cutting. Unlike a gouge, which cuts as the bevel rides against the workpiece, a scraper is held against the # Sharpening a Scraper Sharpening a scraper is easy. The first thing you'll need to do is set the tool rest to match the bevel angle on the scraper, see detail below. With the rest locked in place, creating the burr is just a matter of setting the scraper flat on the rest and________| sliding the cutting edge HMHHHB^^HHp^^B along the edge of the wheel, see photo. As you grind the scraper, a burr forms along the top edge, see inset photo. For curved edges, the technique is a little different. To avoid grinding a flat spot, you'll need to swing the handle to the side as you move the cutting edge across the edge of the wheel, see drawing. SWING SCRAPER AS EDGE GROUND workpiece so only the burr cuts. The nice thing about a scraper is that it's a safe and predictable tool to use. Because the burr that does the cutting is rather short, it limits the "bite" or depth of cut you can make as the workpiece turns. Besides being easy to use, scrapers come in a wide variety of profiles. This includes square-end, round-nosed, and several other profiles. For mail order sources of scrapers, see page 31. sharpening. Regardless of the profile, a bench grinder is the key to creating the burr on the end of the scraper. The important thing is to use the correct type of wheel and the proper grit. For my scrapers (and other turning tools), I use a white aluminum-oxide wheel. It grinds cooler than the grey silicon-carbide wheels normally supplied with most grinders. This way you're less likely to overheat the scraper and draw the temper. To remove a nick or to rough shape a scraper, I use an 80-grit wheel. Then, I follow up with a 120-grit finishing wheel. With the proper wheel in the grinder, creating the burr is a simple matter, see box at left. burnishing a scraper. Although you can use the scraper with the burr that's formed by the grinder, I like a burr that's been burnished, or rubbed, on the end. This creates a burr that's smoother than the one you get from a grinder. And it's also stronger — so you won't have to sharpen the scraper as often. For this type of burr, you still start with a bench grinder — but only to establish the bevel. Once that's set, you need to remove the bun' by honing the top of the scraper on a fine (1000-grit) sharpening stone. With the rough burr removed, you're ready to burnish a smooth one on the end of the scraper. The only problem is the hardness of a highspeed steel scraper makes it difficult to form a burr. To make this task a little easier, there's a simple jig you can use, see the box on page 11. 10 ShopNotes No. 38 |