38 - Ring Boxes, страница 11

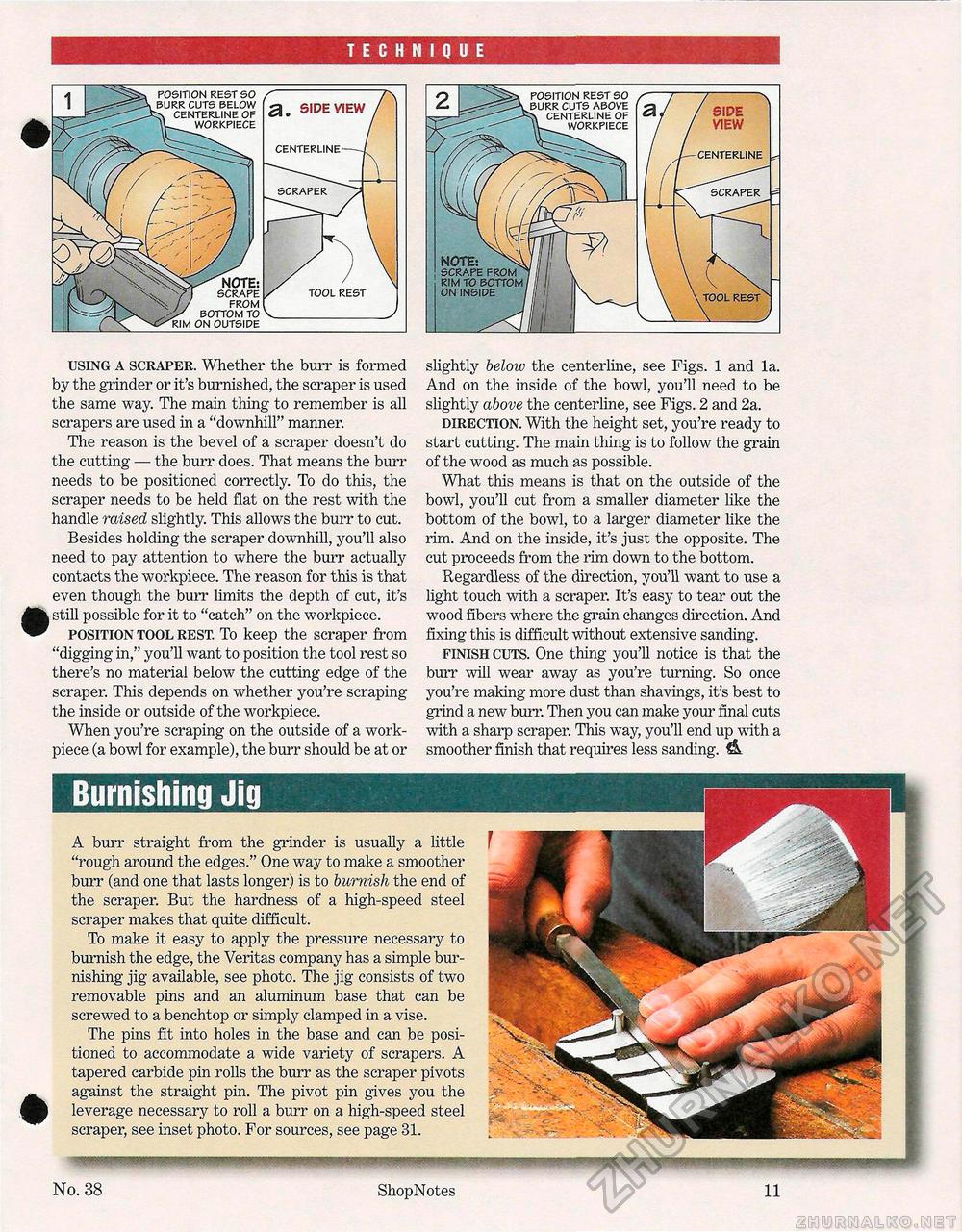

TECHNIQUE a. SIDE VIEW CENTERLINE SCRAPER POSITION REST SO BURR CUTS BELOW CENTERLINE OF WORKPIECE NOTE: SCRAPE FROM BOTTOM TO ON OUTSIDE using a scraper. Whether the burr is formed by the grinder or it's burnished, the scraper is used the same way. The main thing to remember is all scrapers are used in a "downhill" manner. The reason is the bevel of a scraper doesn't do the cutting — the burr does. That means the burr needs to be positioned correctly. To do this, the scraper needs to be held flat on the rest with the handle raised slightly. This allows the burr to cut. Besides holding the scraper downhill, you'll also need to pay attention to where the burr actually contacts the workpiece. The reason for this is that even though the burr limits the depth of cut, it's still possible for it to "catch" on the workpiece. position tool rest. To keep the scraper from "digging in," you'll want to position the tool rest so there's no material below the cutting edge of the scraper. This depends on whether you're scraping the inside or outside of the workpiece. When you're scraping on the outside of a work-piece (a bowl for example), the burr should be at or slightly below the centerline, see Figs. 1 and la. And on the inside of the bowl, you'll need to be slightly above the centerline, see Figs. 2 and 2a. direction. With the height set, you're ready to start cutting. The main thing is to follow the grain of the wood as much as possible. What this means is that on the outside of the bowl, you'll cut from a smaller diameter like the bottom of the bowl, to a larger diameter like the rim. And on the inside, it's just the opposite. The cut proceeds from the rim down to the bottom. Regardless of the direction, you'll want to use a light touch with a scraper. It's easy to tear out the wood fibers where the grain changes direction. And fixing this is difficult without extensive sanding. finish cuts. One thing you'll notice is that the burr will wear away as you're turning. So once you're making more dust than shavings, it's best to grind a new burr. Then you can make your final cuts with a sharp scraper. This way, you'll end up with a smoother finish that requires less sanding. & » A burr straight from the grinder is usually a little "rough around the edges." One way to make a smoother burr (and one that lasts longer) is to burnish the end of the scraper. But the hardness of a high-speed steel scraper makes that quite difficult. To make it easy to apply the pressure necessary to burnish the edge, the Veritas company has a simple burnishing jig available, see photo. The jig consists of two removable pins and an aluminum base that can be screwed to a benchtop or simply clamped in a vise. The pins fit into holes in the base and can be positioned to accommodate a wide variety of scrapers. A tapered carbide pin rolls the burr as the scraper pivots against the straight pin. The pivot pin gives you the leverage necessary to roll a burr on a high-speed steel scraper, see inset photo. For sources, see page 31. r WPI^jimiJl11.'!!'.11.1...II^WIJ'^WJ'l'U'jWI'LliilflPWWiPlliW i"imiMmiii ij'nijij|,mii i wmmm No. 38 ShopNotes 11 |