43 - Build Your Own Dovetail Jig, страница 20

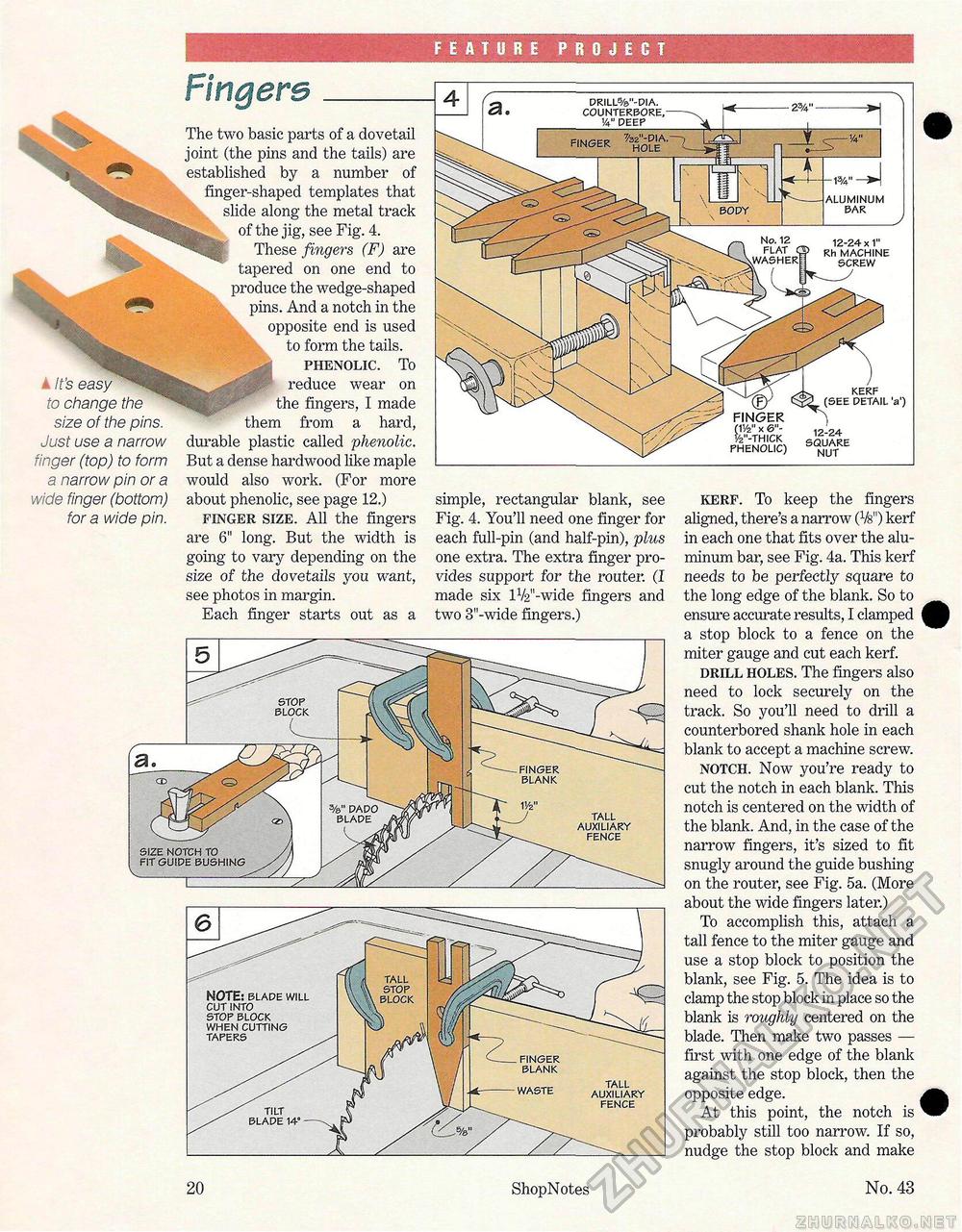

FEATURE PROJECT simple, rectangular blank, see Fig. 4. You'll need one finger for each full-pin (and half-pin), plus one extra. The extra finger provides support for the router. (I made six lV2"-wide fingers and two 3"-wide fingers.) Fingers 4 It's easy to change the size of the pins. Just use a narrow finger (top) to form a narrow pin or a wide finger (bottom) for a wide pin. The two basic parts of a dovetail joint (the pins and the tails) are established by a number of finger-shaped templates that slide along the metal track of the jig, see Fig. 4. These fingers (F) are tapered on one end to produce the wedge-shaped pins. And a notch in the opposite end is used to form the tails. PHENOLIC. To reduce wear on the fingers, I made them from a hard, durable plastic called phenolic. But a dense hardwood like maple would also work. (For more about phenolic, see page 12.) FINGER SIZE. All the fingers are 6" long. But the width is going to vary depending on the size of the dovetails you want, see photos in margin. Each finger starts out as a finger 7/€n?la- DRILLs/a"-DIA. COUNTERBORE, V4" DEEP ALUMINUM BAR _y 12-24 x 1" Rh MACHINE SCREW KERF (SEE DETAIL 'a') (jy2 x e> -1/2"-THICK PHENOLIC) 12-24 SQUARE NUT BODY No. 12 SIZE NOTCH TO FIT GUIDE BUSHING KERF. To keep the fingers aligned, there's a narrow (Vs") kerf in each one that fits over the aluminum bar, see Fig. 4a. This kerf needs to be perfectly square to the long edge of the blank. So to ensure accurate results, I clamped a stop block to a fence on the miter gauge and cut each kerf. DRILL HOLES. The fingers also need to lock securely on the track. So you'll need to drill a counterbored shank hole in each blank to accept a machine screw. NOTCH. Now you're ready to cut the notch in each blank. This notch is centered on the width of the blank. And, in the case of the narrow fingers, it's sized to fit snugly around the guide bushing on the router, see Fig. 5a. (More about the wide fingers later.) To accomplish this, attach a tall fence to the miter gauge and use a stop block to position the blank, see Fig. 5. The idea is to clamp the stop block in place so the blank is roughly centered on the blade. Then make two passes — first with one edge of the blank against the stop block, then the opposite edge. At this point, the notch is probably still too narrow. If so, nudge the stop block and make 20 ShopNotes xj No. 43 FINGER BLANK WASTE AUXILIARY FENCE NOTE: BLADE WILL CUT INTO STOP BLOCK WHEN CUTTING TAPERS |