44 - Grinding Station, страница 12

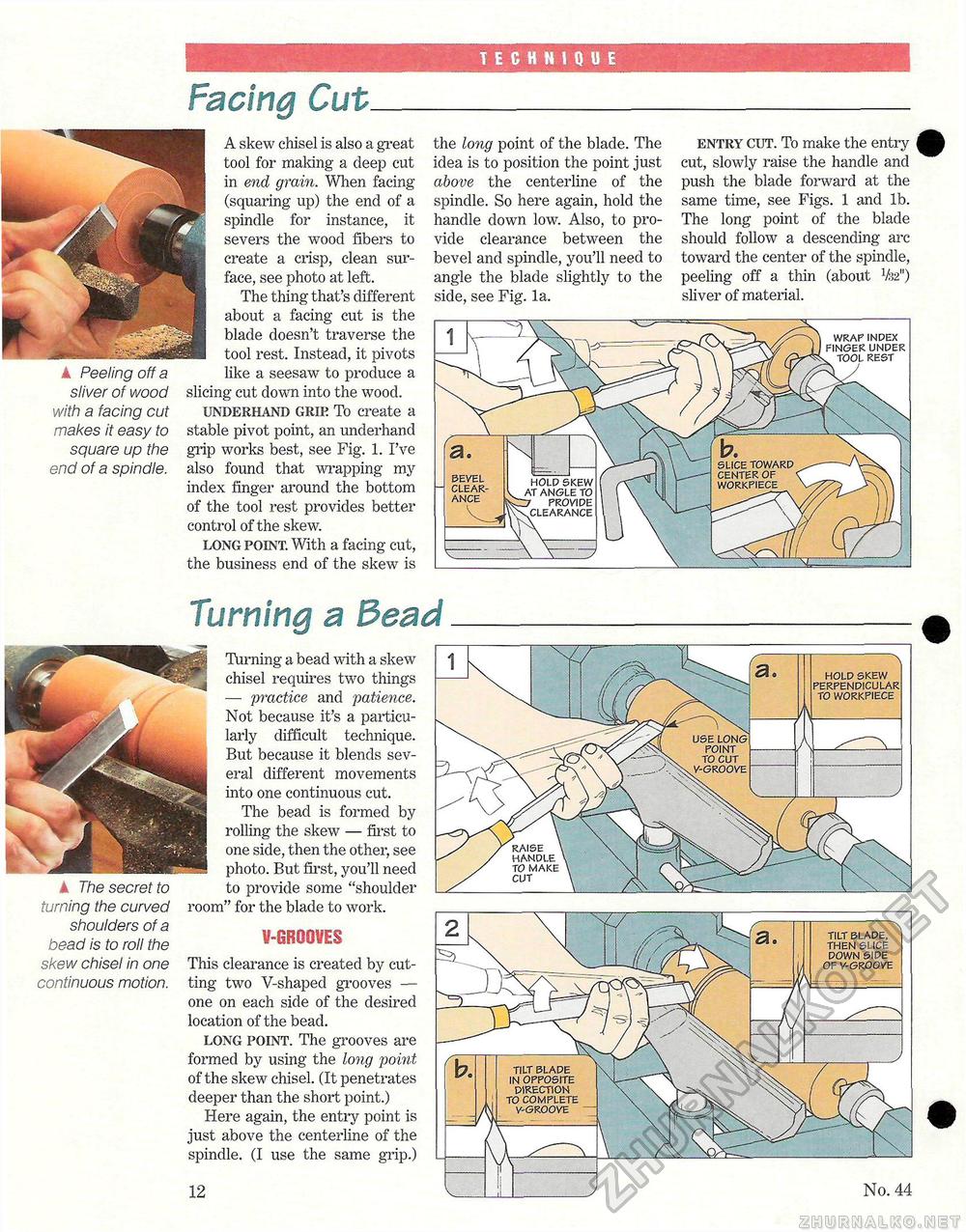

TECHNIQUE Facing Cut.the long point of the blade. The idea is to position the point just above the centerline of the spindle. So here again, hold the handle down low. Also, to provide clearance between the bevel and spindle, you'll need to angle the blade slightly to the side, see Fig. la. entry cut. To make the entry cut, slowly raise the handle and push the blade forward at the same time, see Figs. 1 and lb. The long point of the blade should follow a descending arc toward the center of the spindle, peeling off a thin (about sliver of material. Turning a BeadRAISE . .. , _ HANDLE \ \ TO MAKE \ \ CXP** CUT \ X \ \ _ • -- _ ▲ Peeling off a sliver of wood with a facing cut makes it easy to square up the end of a spindle. A skew chisel is also a great tool for making a deep cut in end grain, When facing (squaring up) the end of a spindle for instance, it severs the wood fibers to create a crisp, clean surface, see photo at left. The thing that's different about a facing cut is the blade doesn't traverse the tool rest. Instead, it pivots like a seesaw to produce a slicing cut down into the wood. underhand grir To create a stable pivot point, an underhand grip works best, see Fig. 1. I've also found that wrapping my index finger around the bottom of the tool rest provides better control of the skew. long point. With a facing cut, the business end of the skew is ▲ The secret to turning the curved shoulders of a bead is to roll the skew chisel in one continuous motion. Turning a bead with a skew chisel requires two things — practice and patience. Not because it's a particularly difficult technique. But because it blends several different movements into one continuous cut. The bead is formed by rolling the skew — first to one side, then the other, see photo. But first, you'll need to provide some "shoulder room" for the blade to work. v-groqves This clearance is created by cutting two V-shaped grooves — one on each side of the desired location of the bead. long point. The grooves are formed by using the long point of the skew chisel. (It penetrates deeper than the short point.) Here again, the entry point is just above the centerline of the spindle. (I use the same grip.) |