44 - Grinding Station, страница 14

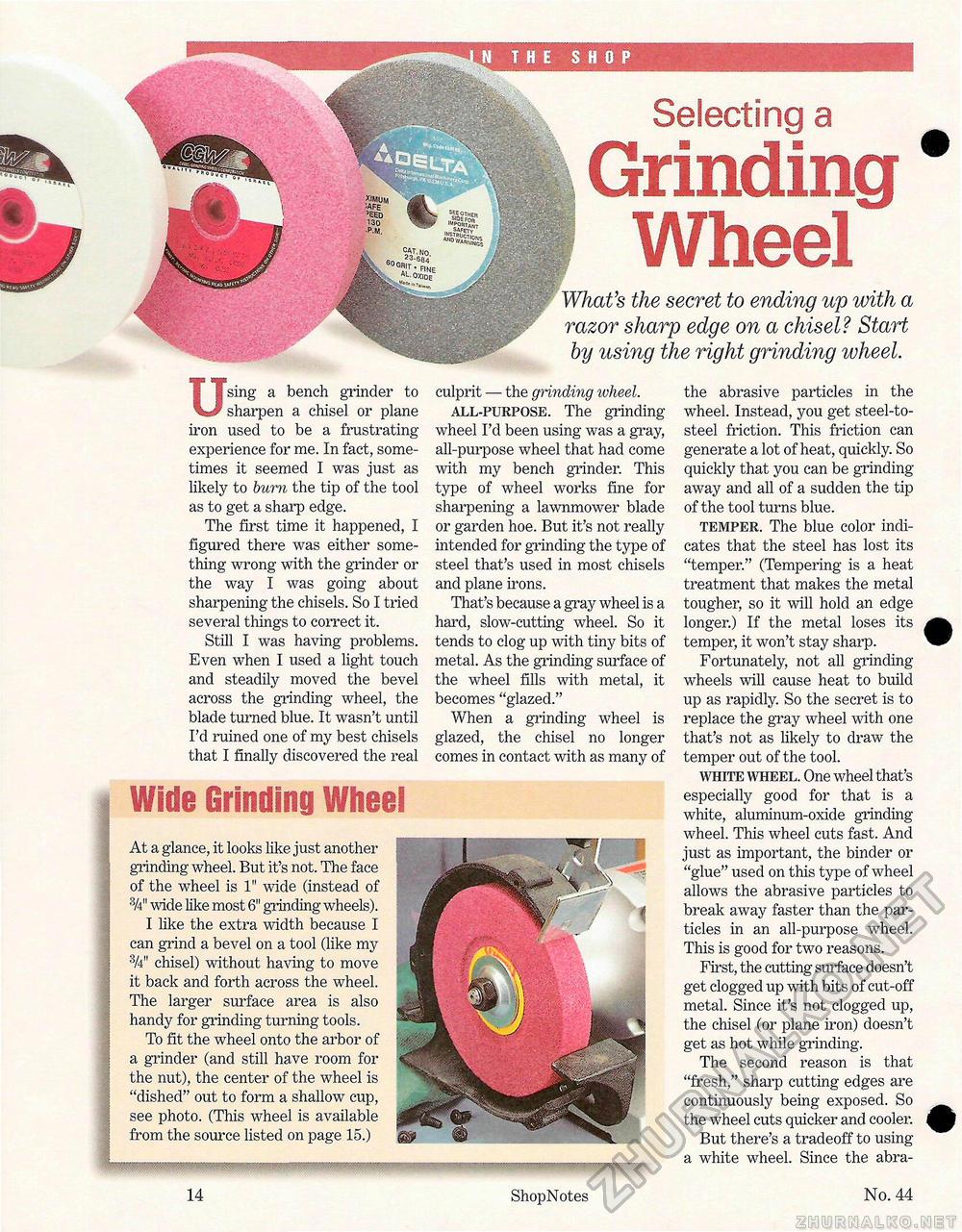

Using a bench grinder to sharpen a chisel or plane iron used to be a frustrating experience for me. In fact, sometimes it seemed I was just as likely to bum the tip of the tool as to get a sharp edge. The first time it happened, I figured there was either something wrong with the grinder or the way I was going about sharpening the chisels. So I tried several things to correct it. Still I was having problems. Even when I used a light touch and steadily moved the bevel across the grinding wheel, the blade turned blue. It wasn't until I'd ruined one of my best chisels that I finally discovered the real Wide Grinding WheelAt a glance, it looks like just another grinding wheel. But it's not. The face of the wheel is 1" wide (instead of 3/4n wide like most 6" grinding wheels). I like the extra width because I can grind a bevel on a tool (like my 3A" chisel) without having to move it back and forth across the wheel. The larger surface area is also handy for grinding turning tools. To fit the wheel onto the arbor of a grinder (and still have room for the nut), the center of the wheel is "dished" out to form a shallow cup, see photo. (This wheel is available from the source listed on page 15.) culprit — the gnnding ivheel. all-purpose. The grinding wheel I'd been using was a gray, all-purpose wheel that had come with my bench grinder. This type of wheel works fine for sharpening a lawnmower blade or garden hoe. But it's not really intended for grinding the type of steel that's used in most chisels and plane irons. That's because a gray wheel is a hard, slow-cutting wheel. So it tends to clog up with tiny bits of metal. As the grinding surface of the wheel fills with metal, it becomes "glazed." When a grinding wheel is glazed, the chisel no longer comes in contact with as many of the abrasive particles in the wheel. Instead, you get steel-to-steel friction. This friction can generate a lot of heat, quickly. So quickly that you can be grinding away and all of a sudden the tip of the tool turns blue. temper. The blue color indicates that the steel has lost its "temper." (Tempering is a heat treatment that makes the metal tougher, so it will hold an edge longer.) If the metal loses its temper, it won't stay sharp. Fortunately, not all grinding wheels will cause heat to build up as rapidly. So the secret is to replace the gray wheel with one that's not as likely to draw the temper out of the tool. white wheel. One wheel that's especially good for that is a white, aluminum-oxide grinding wheel. This wheel cuts fast. And just as important, the binder or "glue" used on this type of wheel allows the abrasive particles to break away faster than the particles in an all-purpose wheel. This is good for two reasons. First, the cutting surface doesn't get clogged up with bits of cut-off metal. Since it's not clogged up, the chisel (or plane iron) doesn't get as hot while grinding. The second reason is that "fresh," sharp cutting edges are continuously being exposed. So the wheel cuts quicker and cooler. But there's a tradeoff to using a white wheel. Since the abra- 14 ShopNotes No. 44 Selecting a Grinding Wheel What's the secret to ending up with a razor sharp edge on a chisel? Start by using the right grinding ivheel. |