44 - Grinding Station, страница 15

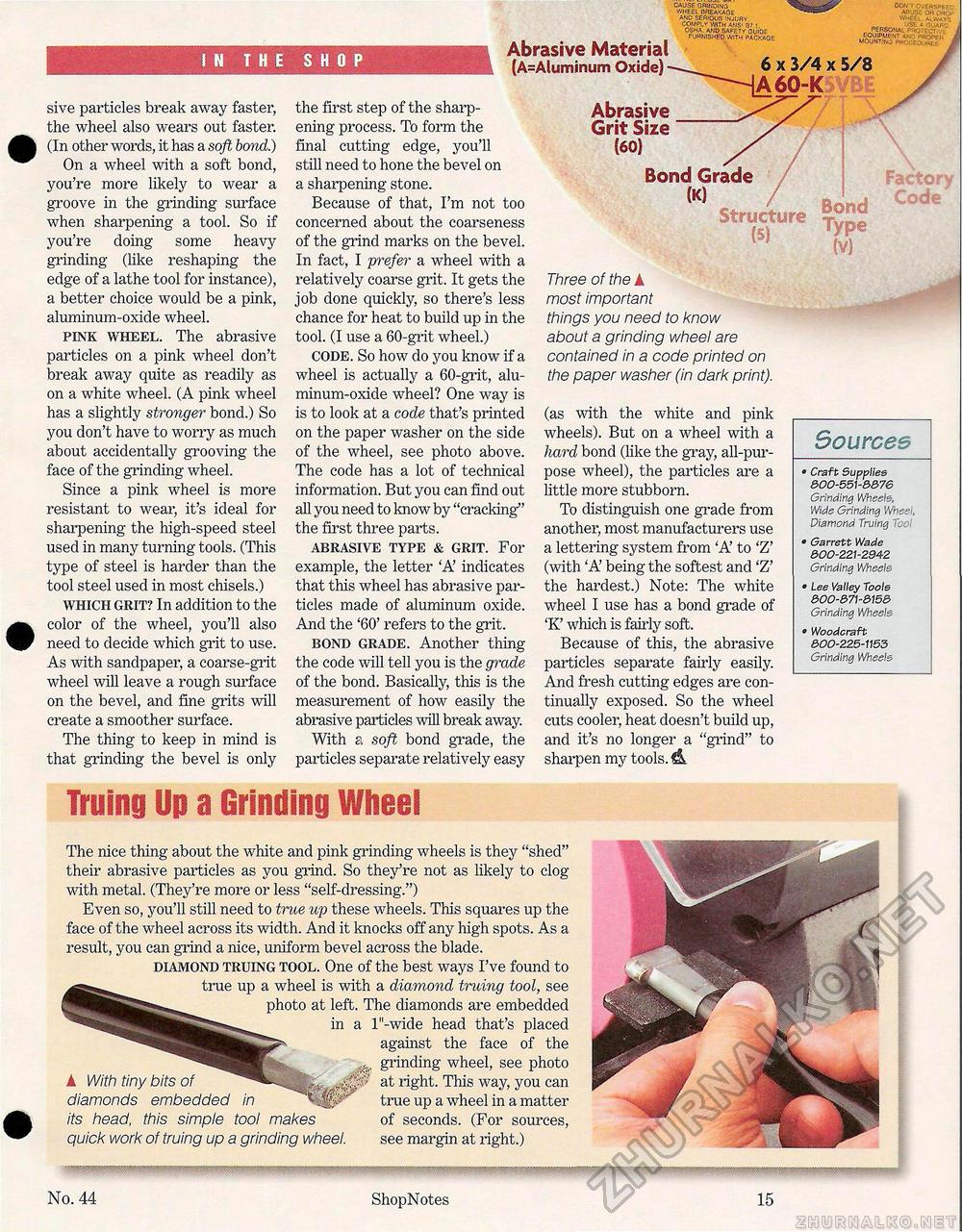

IN THE SHOP Abrasive Material (A=Aluminum Oxide) CAUSE GRINDING WHEEL OflEAKAOE AND SFfilOUS INJURY comply with ams* ay i OSHA AND SAPfc'TY GUIDE FURNISHED WITH PACKAGE OOk"' OVERSPEED ABUSE OH DROP WHEEL ALWAYS UOUNTJhJ P«c' ; j:iHfS" 6 x 3/4 x 5/8 sive particles break away faster, the wheel also wears out faster. (In other words, it has a soft bond.) On a wheel with a soft bond, you're more likely to wear a groove in the grinding surface when sharpening a tool. So if you're doing some heavy grinding (like reshaping the edge of a lathe tool for instance), a better choice would be a pink, aluminum-oxide wheel. pink wheel. The abrasive particles on a pink wheel don't break away quite as readily as on a white wheel. (A pink wheel has a slightly stronger bond.) So you don't have to worry as much about accidentally grooving the face of the grinding wheel. Since a pink wheel is more resistant to wear, it's ideal for sharpening the high-speed steel used in many turning tools. (This type of steel is harder than the tool steel used in most chisels.) which grit? In addition to the color of the wheel, you'll also need to decide which grit to use. As with sandpaper, a coarse-grit wheel will leave a rough surface on the bevel, and fine grits will create a smoother surface. The thing to keep in mind is that grinding the bevel is only the first step of the sharpening process. To form the final cutting edge, you'll still need to hone the bevel on a sharpening stone. Because of that, I'm not too concerned about the coarseness of the grind marks on the bevel. In fact, I prefer a wheel with a relatively coarse grit. It gets the job done quickly, so there's less chance for heat to build up in the tool. (I use a 60-grit wheel.) code. So how do you know if a wheel is actually a 60-grit, aluminum-oxide wheel? One way is is to look at a code that's printed on the paper washer on the side of the wheel, see photo above. The code has a lot of technical information. But you can find out all you need to know by "cracking" the first three parts. abrasive type & grit. For example, the letter 'A' indicates that this wheel has abrasive particles made of aluminum oxicle. And the '60' refers to the grit. bond grade. Another thing the code will tell you is the grade of the bond. Basically, this is the measurement of how easily the abrasive particles will break away. With a soft bond grade, the particles separate relatively easy J Abrasive Grit Size (60) Bond Grade (K) Structure (5) Three of the A most important things you need to know about a grinding wheel are contained in a code printed on the paper washer (in dark print). (as with the white and pink wheels). But on a wheel with a hard bond (like the gray, all-pur-pose wheel), the particles are a little more stubborn. To distinguish one grade from another, most manufacturers use a lettering system from 'A' to 'Z' (with 'A' being the softest and 'Z' the hardest.) Note: The white wheel I use has a bond grade of 'K' which is fairly soft. Because of this, the abrasive particles separate fairly easily. And fresh cutting edges are continually exposed. So the wheel cuts cooler, heat doesn't build up, and it's no longer a "grind" to sharpen my tools. & Bond ode m Sourcee • Craft Supplies 300-551-3376 Grinding Wheels, Wide Grinding Wbee>, Diamond Truing Tool • Garrett Wade 300-221-2942 Grinding Wheels • Lee Valley Tools 300-371-3153 Grinding Wheels • Woodcraft 300-225-1153 Grinding Wheels Truing Up a Grinding WheelThe nice thing about the white and pink grinding wheels is they "shed" their abrasive particles as you grind. So they're not as likely to clog with metal. (They're more or less "self-dressing.") Even so, you'll still need to true up these wheels. This squares up the face of the wheel across its width. And it knocks off any high spots. As a result, you can grind a nice, uniform bevel across the blade. diamond truing tool. One of the best ways I've found to true up a wheel is with a diamond truing tool, see photo at left. The diamonds are embedded in a l"-wide head that's placed against the face of the __grinding wheel, see photo A With tiny bits of iv. at right. This way, you can diamonds embedded in true up a wheel in a matter its head, this simple tool makes of seconds. (For sources, quick work of truing up a grinding wheel. see margin at right.) No. 44 ShopNotes 15 |