49 - Cabinet Maker's Tool Chest, страница 13

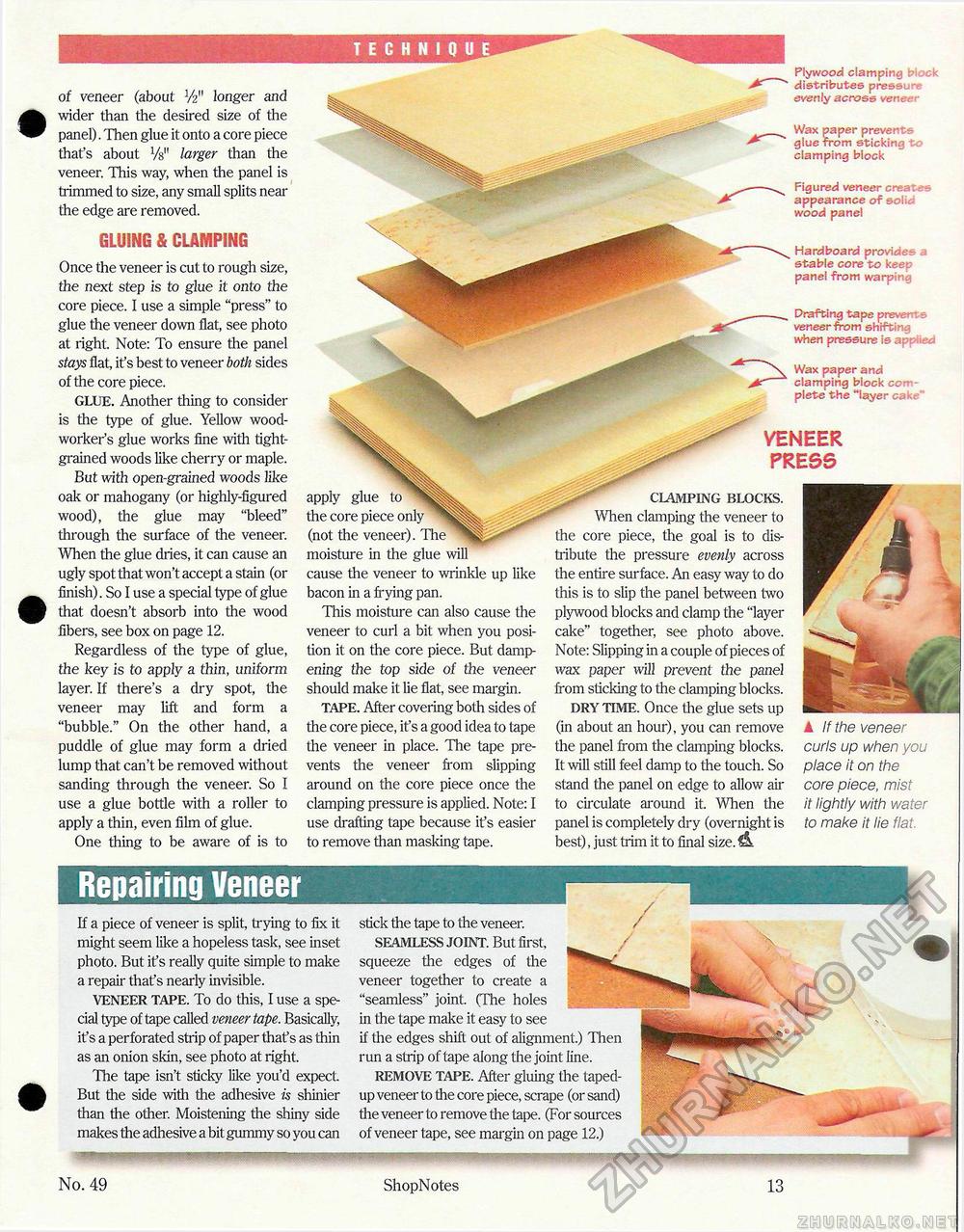

TECHNIQUE of veneer (about V2" longer and wider than the desired size of the panel). Then glue it onto a core piece that's about Vs" larger than the veneer. This way, when the panel is trimmed to size, any small splits near the edge are removed. GLUING & CLAMPING Once the veneer is cut to rough size, the next step is to glue it onto the core piece. I use a simple "press" to glue the veneer down flat, see photo at right. Note: To ensure the panel stays flat, it's best to veneer both sides of the core piece. glue. Another thing to consider is the type of glue. Yellow woodworker's glue works fine with tight-grained woods like cherry or maple. But with open-grained woods like oak or mahogany (or highly-figured wood), the glue may "bleed" through the surface of the veneer. When the glue dries, it can cause an ugly spot that won't accept a stain (or finish). So I use a special type of glue that doesn't absorb into the wood fibers, see box on page 12. Regardless of the type of glue, the key is to apply a thin, uniform layer. If there's a dry spot, the veneer may lift and form a "bubble." On the other hand, a puddle of glue may form a dried lump that can't be removed without sanding through the veneer. So I use a glue bottle with a roller to apply a thin, even film of glue. One thing to be aware of is to Repairing VeneerIf a piece of veneer is split, trying to fix it might seem like a hopeless task, see inset photo. But it's really quite simple to make a repair that's nearly invisible. veneer tape. To do this, I use a special type of tape called veneer tape. Basically, it's a perforated strip of paper that's as thin as an onion skin, see photo at right. The tape isn't sticky like you'd expect. But the side with the adhesive is shinier than the other. Moistening the shiny side makes the adhesive a bit gummy so you can No. 49 stick the tape to the veneer. seamless joint. But first, squeeze the edges of the veneer together to create a "seamless" joint. (The holes in the tape make it easy to see if the edges shift out of alignment.) Then run a strip of tape along the joint line. remove tape. After gluing the taped-up veneer to the core piece, scrape (or sand) the veneer to remove the tape. (For sources of veneer tape, see margin on page 12.) ShopNotes 13 Plywood clamping b ock distributes pressu-e evenly across veneer Wax paper and clamping block cc -plete the "layer g^ n. VENEER PRESS apply glue to the core piece only (not the veneer). The moisture in the glue will cause the veneer to wrinkle up like bacon in a frying pan. This moisture can also cause the veneer to curl a bit when you position it on the core piece. But dampening the top side of the veneer should make it lie flat, see margin. tape. After covering both sides of the core piece, it's a good idea to tape the veneer in place. The tape prevents the veneer from slipping around on the core piece once the clamping pressure is applied. Note: I use drafting tape because it's easier to remove than masking tape. clamping blocks. When clamping the veneer to the core piece, the goal is to distribute the pressure evenly across the entire surface. An easy way to do this is to slip the panel between two plywood blocks and clamp the "layer cake" together, see photo above. Note: Slipping in a couple of pieces of wax paper will prevent the panel from sticking to the clamping blocks. dry time. Once the glue sets up (in about an hour), you can remove the panel from the clamping blocks. It will still feel damp to the touch. So stand the panel on edge to allow air to circulate around it. When the panel is completely dry (overnight is best), just trim it to final size. & A If the veneer curls up when you place it on the core piece, mist it lightly with water to make it lie flat. Wax paper prevents glue from sticking to clamping block Figured veneer creates appearance of soiie wood panel Hardboard provides a stable core to keep panel from warping Drafting tape p never is veneer from shrftir.; when pressure is appweo. |