49 - Cabinet Maker's Tool Chest, страница 28

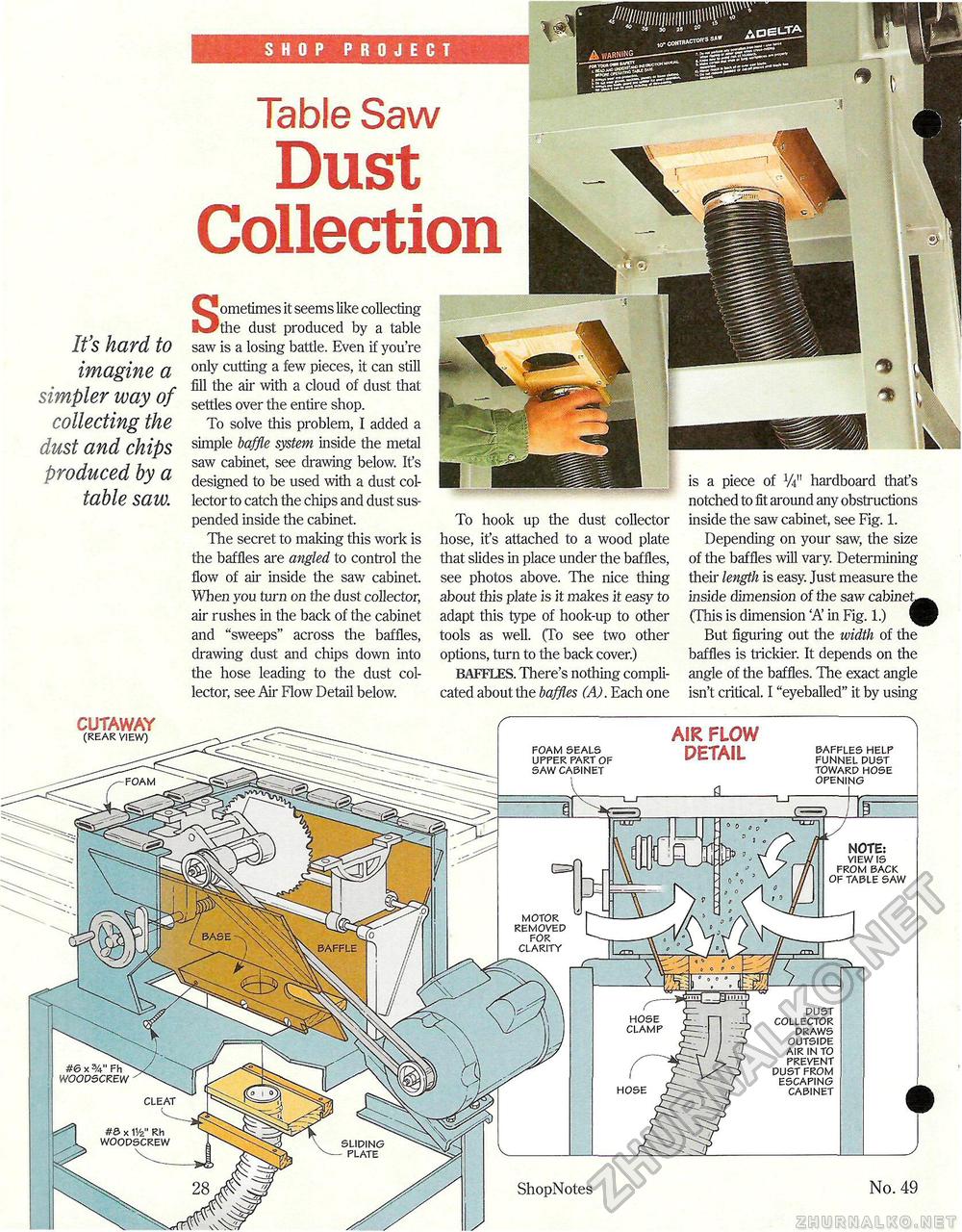

It's hard to SHOP PROJECT Table Saw Dust Collection imagine a simpler way of collecting the dust and chips produced by a table saw. Sometimes it seems like collecting the dust produced by a table saw is a losing battle. Even if you're only cutting a few pieces, it can still fill the air with a cloud of dust that settles over the entire shop. To solve this problem, I added a simple baffle system inside the metal saw cabinet, see drawing below. It's designed to be used with a dust collector to catch the chips and dust suspended inside the cabinet. The secret to making this work is the baffles are angled to control the flow of air inside the saw cabinet. When you turn on the dust collector, air rushes in the back of the cabinet and "sweeps" across the baffles, drawing dust and chips down into the hose leading to the dust collector, see Air Flow Detail below. is a piece of W hardboard that's notched to fit around any obstructions inside the saw cabinet, see Fig. 1. Depending on your saw, the size of the baffles will vary. Determining their length is easy. Just measure the inside dimension of the saw cabinet-(This is dimension A' in Fig. 1.) \ But figuring out the width of the baffles is trickier. It depends on the angle of the baffles. The exact angle isn't critical. I "eyeballed" it by using To hook up the dust collector hose, it's attached to a wood plate that slides in place under the baffles, see photos above. The nice thing about this plate is it makes it easy to adapt this type of hook-up to other tools as well. (To see two other options, turn to the back cover.) BAFFLES. There's nothing complicated about the baffles (A). Each one ShopNotes No. 49 #6 x Fh WOOUSCREW CLEAT AIR FLOW DETAIL BAFFLES HELP FUNNEL PUST TOWARD HOSE OPENING : (REAR VIEW) NOTE: VIEW IS FROM BACK OF TABLE SAW MOTOR REMOVEP FOR CLARITY FOAM SEALS UPPER PART OF SAW CABINET PUST COLLECTOR PRAWS OUTSIPE AIR IN TO PREVENT PUST FROM ESCAPING CABINET HOSE CLAMP |