51 - Band Saw Upgrade, страница 28

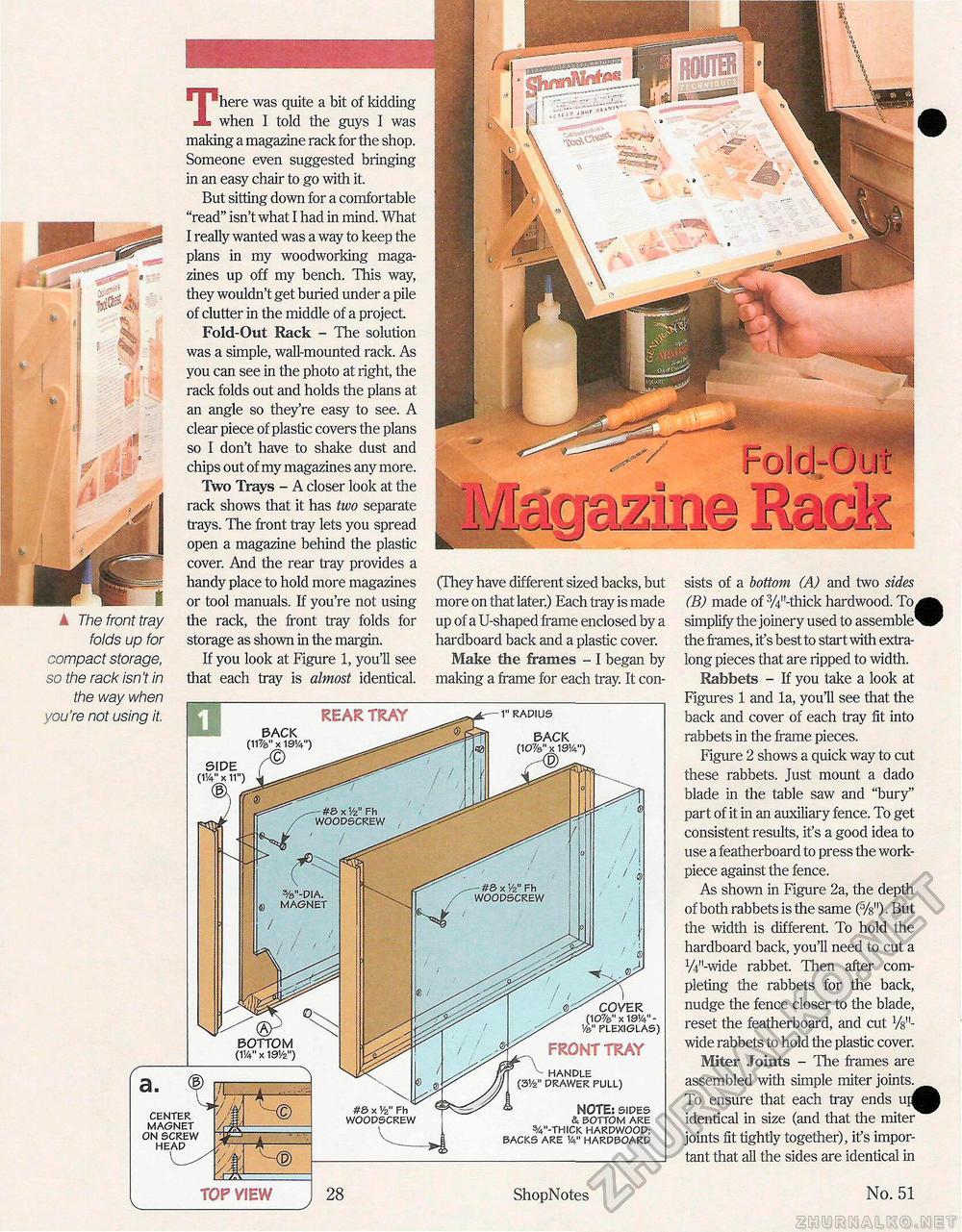

|HKU9 . J * A **' ▲ The front tray folds up for compact storage, so the rack isn't in the way when you're not using it. There was quite a bit of kidding when I told the guys I was making a magazine rack for the shop. Someone even suggested bringing in an easy chair to go with it. But sitting down for a comfortable "read" isn't what I had in mind. What I really wanted was a way to keep the plans in my woodworking magazines up off my bench. This way they wouldn't get buried under a pile of clutter in the middle of a project. Fold-Out Rack - The solution was a simple, wall-mounted rack. As you can see in the photo at right, the rack folds out and holds the plans at an angle so they're easy to see. A clear piece of plastic covers the plans so I don't have to shake dust and chips out of my magazines any more. Two Trays - A closer look at the rack shows that it has two separate trays. The front tray lets you spread open a magazine behind the plastic cover. And the rear tray provides a handy place to hold more magazines or tool manuals. If you're not using the rack, the front tray folds for storage as shown in the margin. If you look at Figure 1, you'll see that each tray is almost identical. tVMcf^ (They have different sized backs, but more on that later.) Each tray is made up of a U-shaped frame enclosed by a hardboard back and a plastic cover. Make the frames - I began by making a frame for each tray. It con-

COV ER (10%" x 191/4m-v&" plexiglas) FRONT TRAY handle " drawer full) NOTE: sides & bottom are % "-thick hardwood; backs are %" hardboard TOP VIEW 28 ShopNotes Fold-Out rvrlfjk sists of a bottom (A) and two sides (B) made of 3/4n-thick hardwood. To, simplify the joinery used to assemble' the frames, it's best to start with extra-long pieces that are ripped to width. Rabbets - If you take a look at Figures 1 and la, you'll see that the back and cover of each tray lit into rabbets in the frame pieces. Figure 2 shows a quick way to cut these rabbets. Just mount a dado blade in the table saw and "bury" part of it in an auxiliary fence. To get consistent results, it's a good idea to use a featherboard to press the work-piece against the fence. As shown in Figure 2a, the depth of both rabbets is the same (5/8M). But the width is different. To hold the hardboard back, you'll need to cut a V4"-wide rabbet. Then after completing the rabbets for the back, nudge the fence closer to the blade, reset the featherboard, and cut Vs"-wide rabbets to hold the plastic cover. Miter Joints - The frames are assembled with simple miter joints. To ensure that each tray ends u;^^ identical in size (and that the miter joints fit tightly together), it's important that all the sides are identical in No. 51 |