51 - Band Saw Upgrade, страница 27

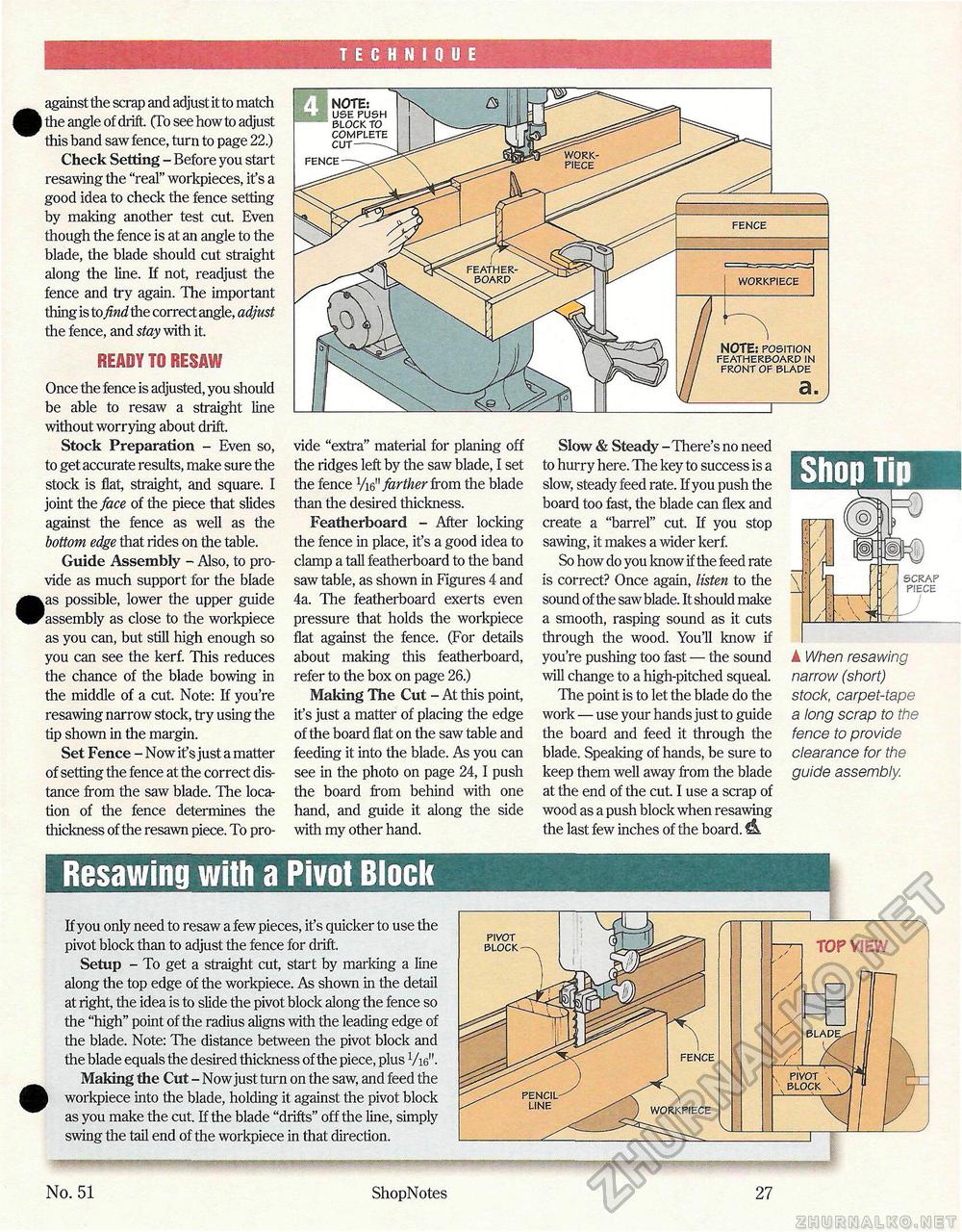

against the scrap and adjust it to match I the angle of drift (To see how to adjust this band saw fence, turn to page 22.) Check Setting - Before you start resawing the "real" workpieces, ifs a good idea to check the fence setting by making another test cut. Even though the fence is at an angle to the blade, the blade should cut straight along the line. If not, readjust the fence and try again. The important thing is to find the correct angle, adjust the fence, and stay with it. READY TO RESaW Once the fence is adjusted, you should be able to resaw a straight line without worrying about drift. Stock Preparation - Even so, to get accurate results, make sure the stock is flat, straight, and square. I joint the face of the piece that slides against the fence as well as the bottom edge that rides on the table. Guide Assembly - Also, to provide as much support for the blade .as possible, lower the upper guide 'assembly as close to the workpiece as you can, but still high enough so you can see the kerf. This reduces the chance of the blade bowing in the middle of a cut. Note: If you're resawing narrow stock, try using the tip shown in the margin. Set Fence - Now if s just a matter of setting the fence at the correct distance from the saw blade. The location of the fence determines the thickness of the resawn piece. To pro vide "extra" material for planing off the ridges left by the saw blade, I set the fence Vi6" farther from the blade than the desired thickness. Featherboard - After locking the fence in place, ifs a good idea to clamp a tall featherboard to the band saw table, as shown in Figures 4 and 4a. The featherboard exerts even pressure that holds the workpiece flat against the fence. (For details about making this featherboard, refer to the box on page 26.) Making The Cut - At this point, ifs just a matter of placing the edge of the board flat on the saw table and feeding it into the blade. As you can see in the photo on page 24,1 push the board from behind with one hand, and guide it along the side with my other hand. Slow & Steady - There's no need to hurry here. The key to success is a slow, steady feed rate. If you push the board too fast, the blade can flex and create a "barrel" cut. If you stop sawing, it makes a wider kerf. So how do you know if the feed rate is correct? Once again, listen to the sound of the saw blade. It should make a smooth, rasping sound as it cuts through the wood. You'll know if you're pushing too fast — the sound will change to a high-pitched squeal. The point is to let the blade do the work — use your hands just to guide the board and feed it through the blade. Speaking of hands, be sure to keep them well away from the blade at the end of the cut. I use a scrap of wood as a push block when resawing the last few inches of the board. & Shop Tip A When resawing narrow (short) stock, carpet-tape a long scrap to the fence to provide clearance for the guide assembly. Resawing with a Pivot BlockIf you only need to resaw a few pieces, ifs quicker to use the pivot block than to adjust the fence for drift Setup - To get a straight cut, start by marking a line along the top edge of the workpiece. As shown in the detail at right the idea is to slide the pivot block along the fence so the "high" point of the radius aligns with the leading edge of the blade. Note: The distance between the pivot block and the blade equals the desired thickness of the piece, plus Vie". Making the Cut - Now just turn on the saw, and feed the workpiece into the blade, holding it against the pivot block as you make the cut. If the blade "drifts" off the line, simply swing the tail end of the workpiece in that direction. TOP VIEW PIVOT BLOCK WORKPIECE \ PIVOT \ ' BLOCK v No. 51 ShopNotes 27 |