51 - Band Saw Upgrade, страница 24

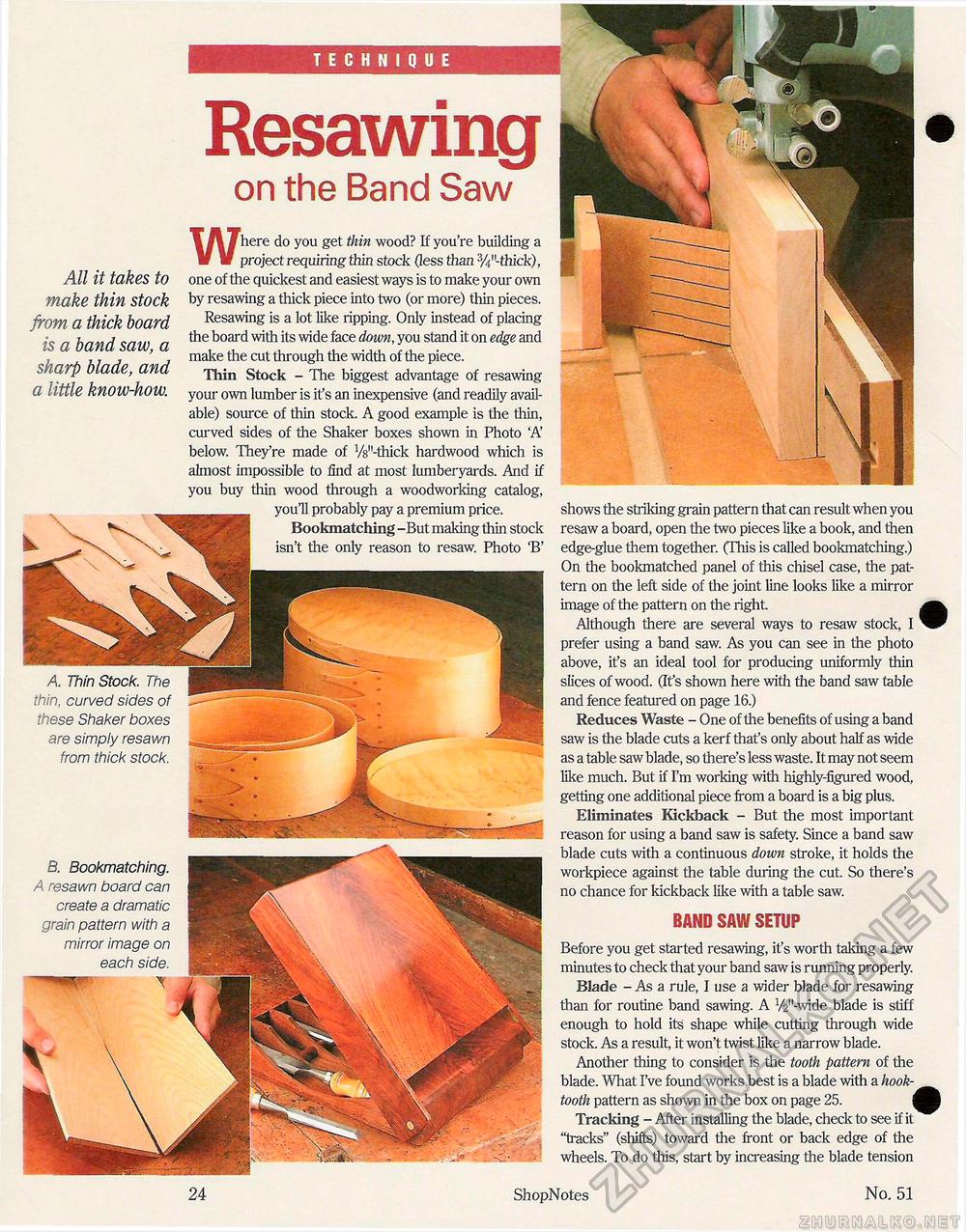

TECHNIQUE Resawing on the Band Saw shows the striking grain pattern that can result when you resaw a board, open the two pieces like a book, and then edge-glue them together. (This is called bookmatching.) On the bookmatched panel of this chisel case, the pattern on the left side of the joint line looks like a mirror image of the pattern on the right. Although there are several ways to resaw stock, I prefer using a band saw. As you can see in the photo above, it's an ideal tool for producing uniformly thin slices of wood. (It's shown here with the band saw table and fence featured on page 16.) Reduces Waste - One of the benefits of using a band saw is the blade cuts a kerf that's only about half as wide as a table saw blade, so there's less waste. It may not seem like much. But if I'm working with highly-figured wood, getting one additional piece from a board is a big plus. Eliminates Kickback - But the most important reason for using a band saw is safety. Since a band saw blade cuts with a continuous down stroke, it holds the workpiece against the table during the cut. So there's no chance for kickback like with a table saw. band saw setup Before you get started resawing, it's worth taking a few minutes to check that your band saw is running properly. Blade - As a rule, I use a wider blade for resawing than for routine band sawing. A V^'-wide blade is stiff enough to hold its shape while cutting through wide stock. As a result, it won't twist like a narrow blade. Another thing to consider is the tooth pattern of the blade. What I've found works best is a blade with a hook-tooth pattern as shown in the box on page 25. | Tracking - After installing the blade, check to see if it "tracks" (shifts) toward the front or back edge of the wheels. To do this, start by increasing the blade tension Where do you get thin wood? If you're building a project requiring thin stock (less than % "-thick), one of the quickest and easiest ways is to make your own by resawing a thick piece into two (or more) thin pieces. Resawing is a lot like ripping. Only instead of placing the board with its wide face down, you stand it on edge and make the cut through the width of the piece. Thin Stock - The biggest advantage of resawing your own lumber is it's an inexpensive (and readily available) source of thin stock. A good example is the thin, curved sides of the Shaker boxes shown in Photo 'A' below. They're made of 1/sM-thick hardwood which is almost impossible to find at most lumberyards. And if you buy thin wood through a woodworking catalog, youH probably pay a premium price. Bookmatching -But making thin stock isn't the only reason to resaw. Photo 'B' A. Thin Stock. The thin, curved sides of these Shaker boxes are simply resawn from thick stock. All it takes to make thin stock from a thick board is a band saw, a sharp blade, and a little know-how. B. Bookmatching. A resawn board can create a dramatic grain pattern with a mirror image on each side. 24 ShopNotes No. 51 |