58 - Miter Saw Station, страница 24

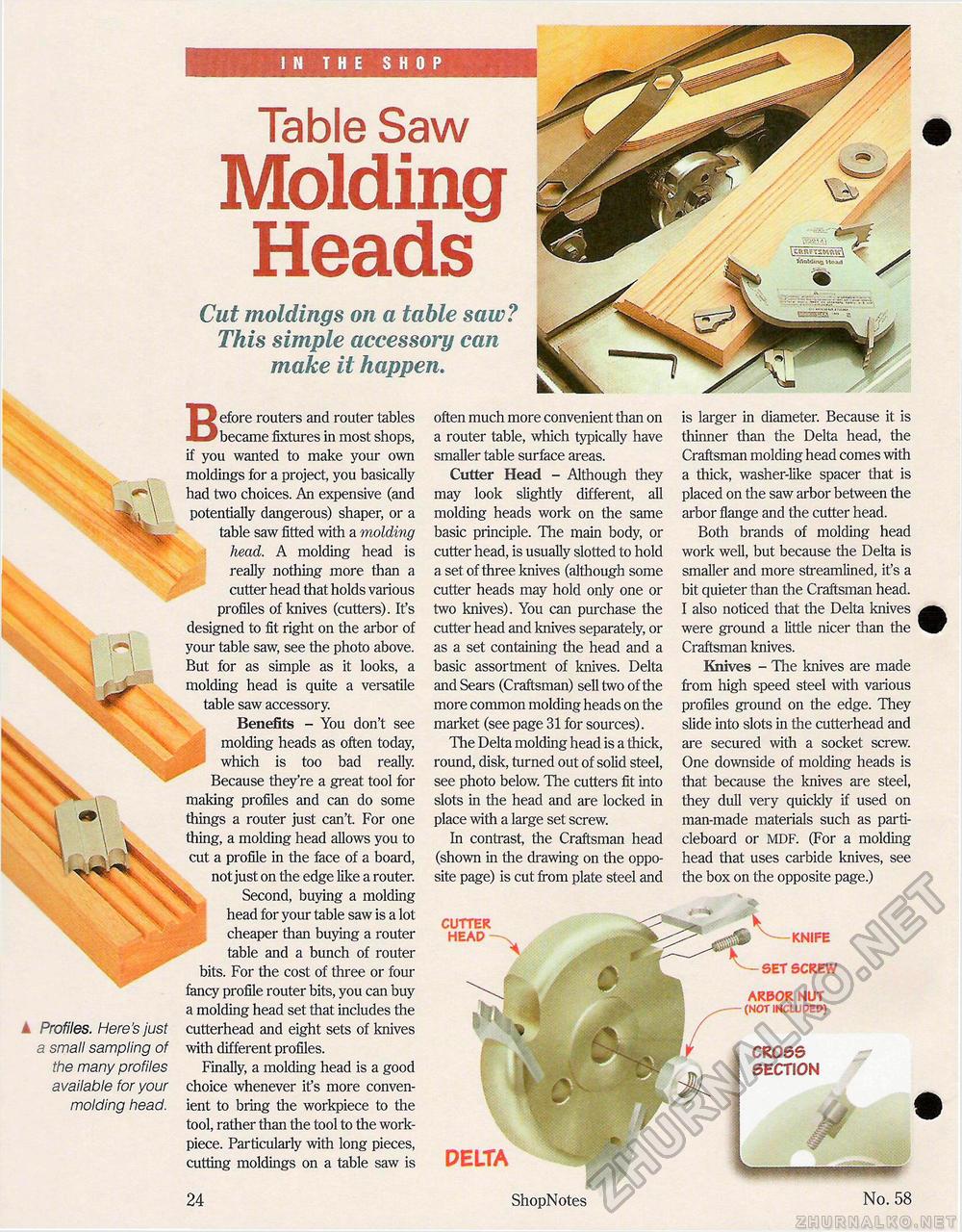

IN THE SHOP Table Saw Molding HeadsCut moldings on a table saw? This simple accessory can make it happen. k Profiles. Here's just a small sampling of the many profiles available for your molding head. Before routers and router tables became fixtures in most shops, if you wanted to make your own moldings for a project, you basically had two choices. An expensive (and potentially dangerous) shaper, or a table saw fitted with a molding head. A molding head is really nothing more than a cutter head that holds various profiles of knives (cutters). It's designed to fit right on the arbor of your table saw, see the photo above. But for as simple as it looks, a molding head is quite a versatile table saw accessory. Benefits - You don't see molding heads as often today, which is too bad really. Because they're a great tool for making profiles and can do some things a router just can't For one thing, a molding head allows you to cut a profile in the face of a board, not just on the edge like a router. Second, buying a molding head for your table saw is a lot cheaper than buying a router table and a bunch of router bits. For the cost of three or four fancy profile router bits, you can buy a molding head set that includes the cutterhead and eight sets of knives with different profiles. Finally, a molding head is a good choice whenever it's more convenient to bring the workpiece to the tool, rather than the tool to the work-piece. Particularly with long pieces, cutting moldings on a table saw is often much more convenient than on a router table, which typically have smaller table surface areas. Cutter Head - Although they may look slightly different, all molding heads work on the same basic principle. The main body, or cutter head, is usually slotted to hold a set of three knives (although some cutter heads may hold only one or two knives). You can purchase the cutter head and knives separately, or as a set containing the head and a basic assortment of knives. Delta and Sears (Craftsman) sell two of the more common molding heads on the market (see page 31 for sources). The Delta molding head is a thick, round, disk, turned out of solid steel, see photo below. The cutters fit into slots in the head and are locked in place with a large set screw. In contrast, the Craftsman head (shown in the drawing on the opposite page) is cut from plate steel and CUTTER HEAD is larger in diameter. Because it is thinner than the Delta head, the Craftsman molding head comes with a thick, washer-like spacer that is placed on the saw arbor between the arbor flange and the cutter head. Both brands of molding head work well, but because the Delta is smaller and more streamlined, it's a bit quieter than the Craftsman head. I also noticed that the Delta knives were ground a little nicer than the Craftsman knives. Knives - The knives are made from high speed steel with various profiles ground on the edge. They slide into slots in the cutterhead and are secured with a socket screw. One downside of molding heads is that because the knives are steel, they dull very quickly if used on man-made materials such as parti-cleboard or MDF. (For a molding head that uses carbide knives, see the box on the opposite page.) — KNIFE SET SCREW ARBOR NUT (NOT INCLUDED) CROSS SECTION DELTA 24 ShopNotes No. 58 TVTittjii'vnrj tt«y.vc!l |