69 - Bench Top Storage System, страница 18

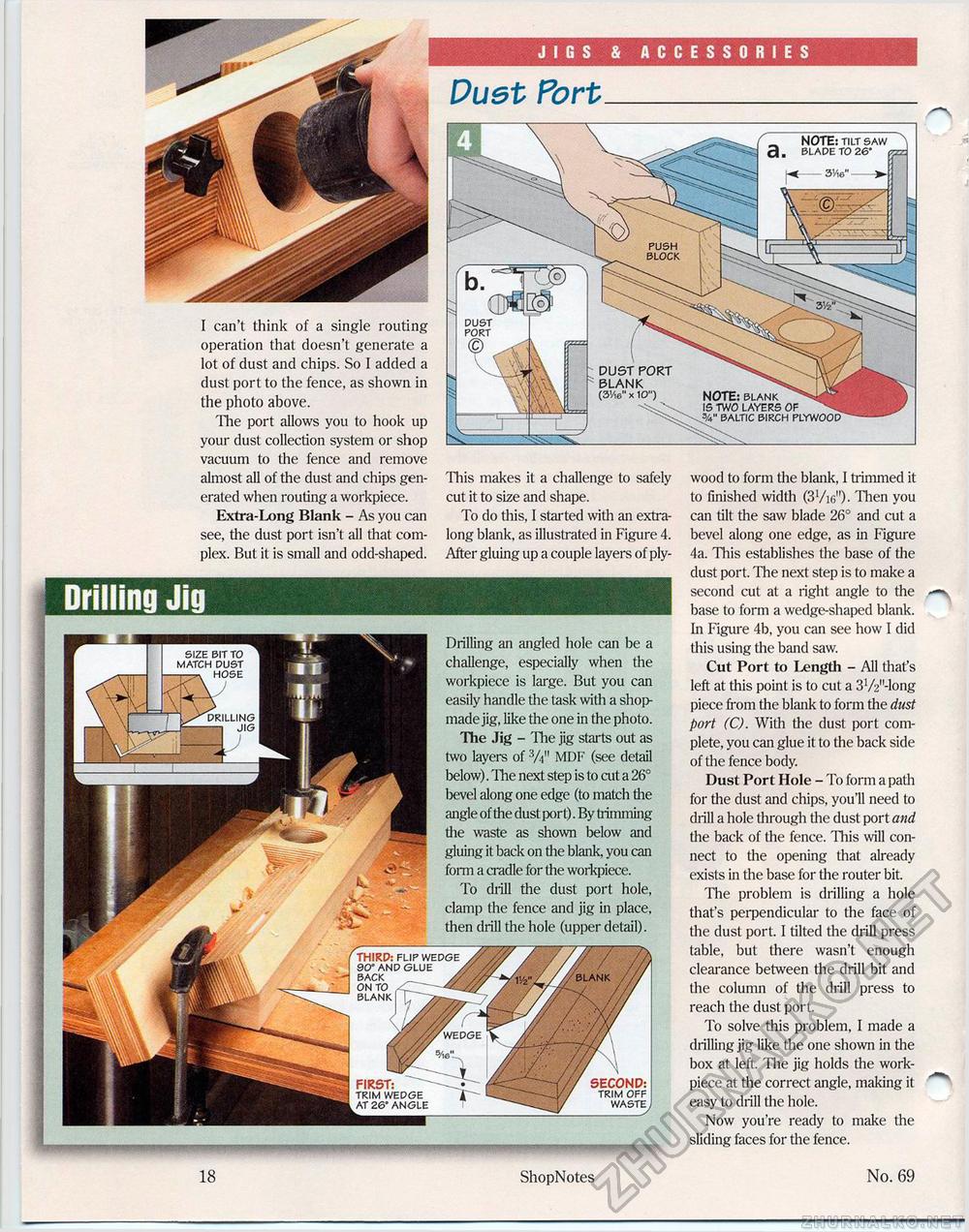

JIGS & ACCESSORIES Duet Port I can't think of a single routing operation that doesn't generate a lot of dust and chips. So I added a dust port to the fence, as shown in the photo above. 'Die port allows you to hook up your dust collection system or shop vacuum to the fence and remove almost all of the dust and chips generated when routing a workpiece. Extra-Long Blank - As you can see, the dust port isn't all that complex. But it is small and odd-shaped. This makes it a challenge to safely cut it to size and shape. To do this, I started with an extra-long blank, as illustrated in Figure 4. After gluing up a couple layers of ply wood to form the blank, 1 trimmed it to finished width (3Vi6")- Then you can tilt the saw blade 26° and cut a bevel along one edge, as in Figure 4a. This establishes the base of the dust port. The next step is to make a second cut at a right angle to the base to form a wedge-shaped blank. In Figure 4b, you can see how I did this using die band saw. Cut Port to Length - All that's left at this point is to cut a 31/2M-long piece from the blank to form the dust port (C). With the dust port complete, you can glue it to the back side of the fence body. Dust Port Hole - To form a path for the dust and chips, you'll need to drill a hole through die dust port and the back of the fence. This will connect to the opening that already exists in die base for the router bit. The problem is drilling a hole that's perpendicular to the face of the dust port. I tilted the drill press table, but there wasn't enough clearance between the drill bit and the column of the drill press to reach the dust port. To solve this problem, I made a drilling jig like die one shown in the box at left. The jig holds the work-piece at the correct angle, making it easy to drill the hole. Now you're ready to make the sliding faces for the fence. DUST PORT BLANK (31/ie" x 10") NOTE: blank is two layer5 of %" baltic birch , PRILLING 55S1 JIG BLANK WEDGE Drilling JigDrilling an angled hole can be a challenge, especially when the workpiece is large. But you can easily handle die task with a shop-made jig, like the one in the photo. The Jig - The jig starts out as two layers of 3/i" MDF (see detail below). The next step is to ait a 26° bevel along one edge (to match die angle of the dust port). By trimming the waste as shown below and gluing it back on die blank, you can form a cradle for the workpiece. To drill the dust port hole, clamp the fence and jig in place, then drill the hole (upper detail). THIRD: FLIP WEDGE 90' AND GLUE BACK _ ONTO BLANK r FIRST: TRIM WEDGE . AT 26° ANGLE SECOND: TRIM OFF WASTE/ SIZE BIT TO MATCH DUST HOSE 18 ShopNotes No. 69 |