82 - The Complete Miter Saw Workstation, страница 24

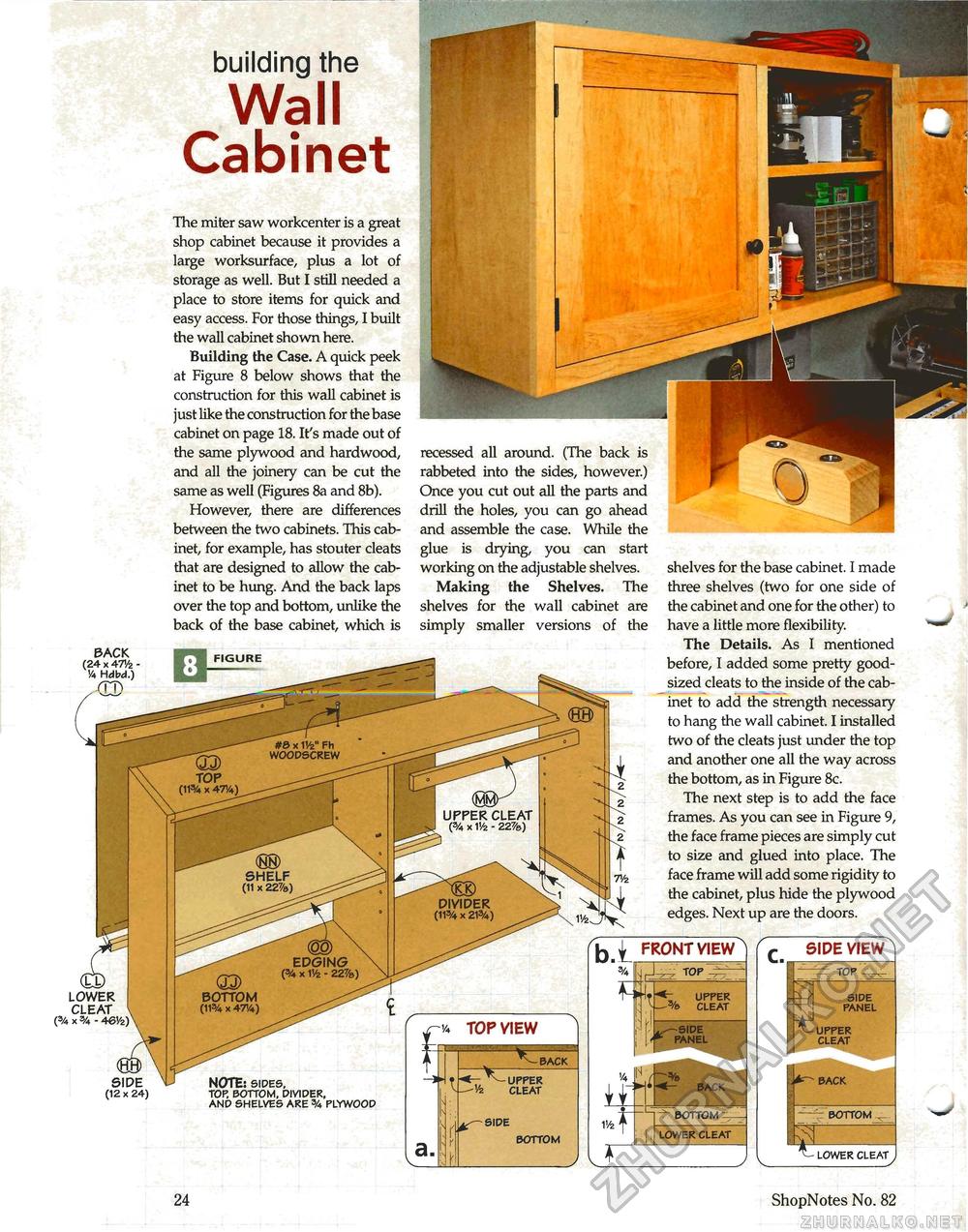

BACK (24 x 47V2 -Va Hdbd.) .-CO) LOWER CLEAT (% X % - 46'/2) SIDE (12 x 24) building the Wall Cabinet The miter saw workcenter is a great shop cabinet because it provides a large worksurface, plus a lot of storage as well. But I still needed a place to store items for quick and easy access. For those things, I built the wall cabinet shown here. Building the Case. A quick peek at Figure 8 below shows that the construction for this wall cabinet is just like the construction for the base cabinet on page 18. It's made out of the same plywood and hardwood, and all the joinery can be cut the same as well (Figures 8a and 8b). However, there are differences between the two cabinets. This cabinet, for example, has stouter cleats that are designed to allow the cabinet to be hung. And the back laps over the top and bottom, unlike the back of the base cabinet, which is recessed all around. (The back is rabbeted into the sides, however.) Once you cut out all the parts and drill the holes, you can go ahead and assemble the case. While the glue is drying, you can start working on the adjustable shelves. Making the Shelves. The shelves for the wall cabinet are simply smaller versions of the shelves for the base cabinet. I made three shelves (two for one side of the cabinet and one for the other) to have a little more flexibility. The Details. As I mentioned before, I added some pretty good-sized cleats to the inside of the cabinet to add the strength necessary to hang the wall cabinet. I installed two of the cleats just under the top and another one all the way across the bottom, as in Figure 8c. The next step is to add the face frames. As you can see in Figure 9, the face frame pieces are simply cut to size and glued into place. The face frame will add some rigidity to the cabinet, plus hide the plywood edges. Next up are the doors. SIDE VIEW c. TOP re SIDE PANEL upper cleat PACK BOTTOM LOWER CLEAT 24 ShopNotes No. 82 |