82 - The Complete Miter Saw Workstation, страница 27

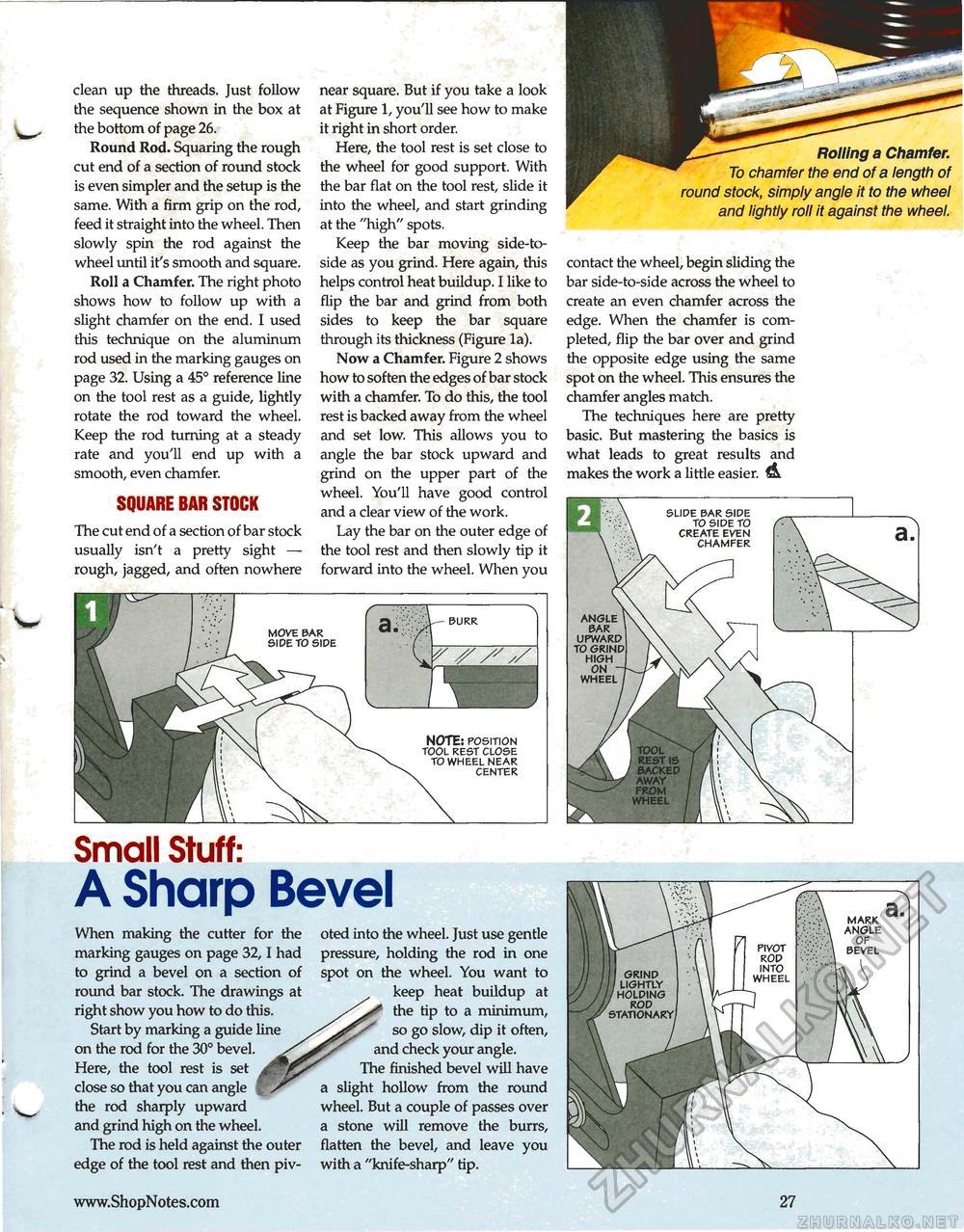

\ Small Stuff: A Sharp Bevel When making the cutter for the oted into the wheel. Just use gentle marking gauges on page 32,1 had pressure, holding the rod in one to grind a bevel on a section of spot on the wheel. You want to round bar stock. The drawings at keep heat buildup at right show you how to do this. the tip to a minimum, Start by marking a guide line so 8° slow, dip it often, on the rod for the 30° bevel. /^^Ss and check your angle. Here, the tool rest is set The finished bevel will have close so that you can angle a slight hollow from the round the rod sharply upward wheel. But a couple of passes over and grind high on the wheel. a stone will remove the burrs, The rod is held against the outer flatten the bevel, and leave you edge of the tool rest and then piv- with a "knife-sharp" tip. Rolling a Chamfer. To chamfer the end of a length of round stock, simply angle it to the wheel and lightly roll it against the wheel. contact the wheel, begin sliding the bar side-to-side across the wheel to create an even chamfer across the edge. When the chamfer is completed, flip the bar over and grind the opposite edge using the same spot on the wheel. This ensures the chamfer angles match. The techniques here are pretty basic. But mastering the basics is what leads to great results and makes the work a little easier. clean up the threads. Just follow the sequence shown in the box at the bottom of page 26. Round Rod. Squaring the rough cut end of a section of round stock is even simpler and the setup is the same. With a firm grip on the rod, feed it straight into the wheel. Then slowly spin the rod against the wheel until it's smooth and square. Roll a Chamfer. The right photo shows how to follow up with a slight chamfer on the end. I used this technique on the aluminum rod used in the marking gauges on page 32. Using a 45° reference line on the tool rest as a guide, lightly rotate the rod toward the wheel. Keep the rod turning at a steady rate and you'll end up with a smooth, even chamfer. SQUARE BAR STOCK The cut end of a section of bar stock usually isn't a pretty sight — rough, jagged, and often nowhere near square. But if you take a look at Figure 1, you'll see how to make it right in short order. Here, the tool rest is set close to the wheel for good support. With the bar flat on the tool rest, slide it into the wheel, and start grinding at the "high" spots. Keep the bar moving side-to-side as you grind. Here again, this helps control heat buildup. I like to flip the bar and grind from both sides to keep the bar square through its thickness (Figure la). Now a Chamfer. Figure 2 shows how to soften the edges of bar stock with a chamfer. To do this, the tool rest is backed away from the wheel and set low. This allows you to angle the bar stock upward and grind on the upper part of the wheel. You'll have good control and a clear view of the work. Lay the bar on the outer edge of the tool rest and then slowly tip it forward into the wheel. When you NOTE: position tool rest close to wheel near center move par side to side burr slide bar side to side to create even chamfer angle bar upward to WHEEL 27 |