82 - The Complete Miter Saw Workstation, страница 40

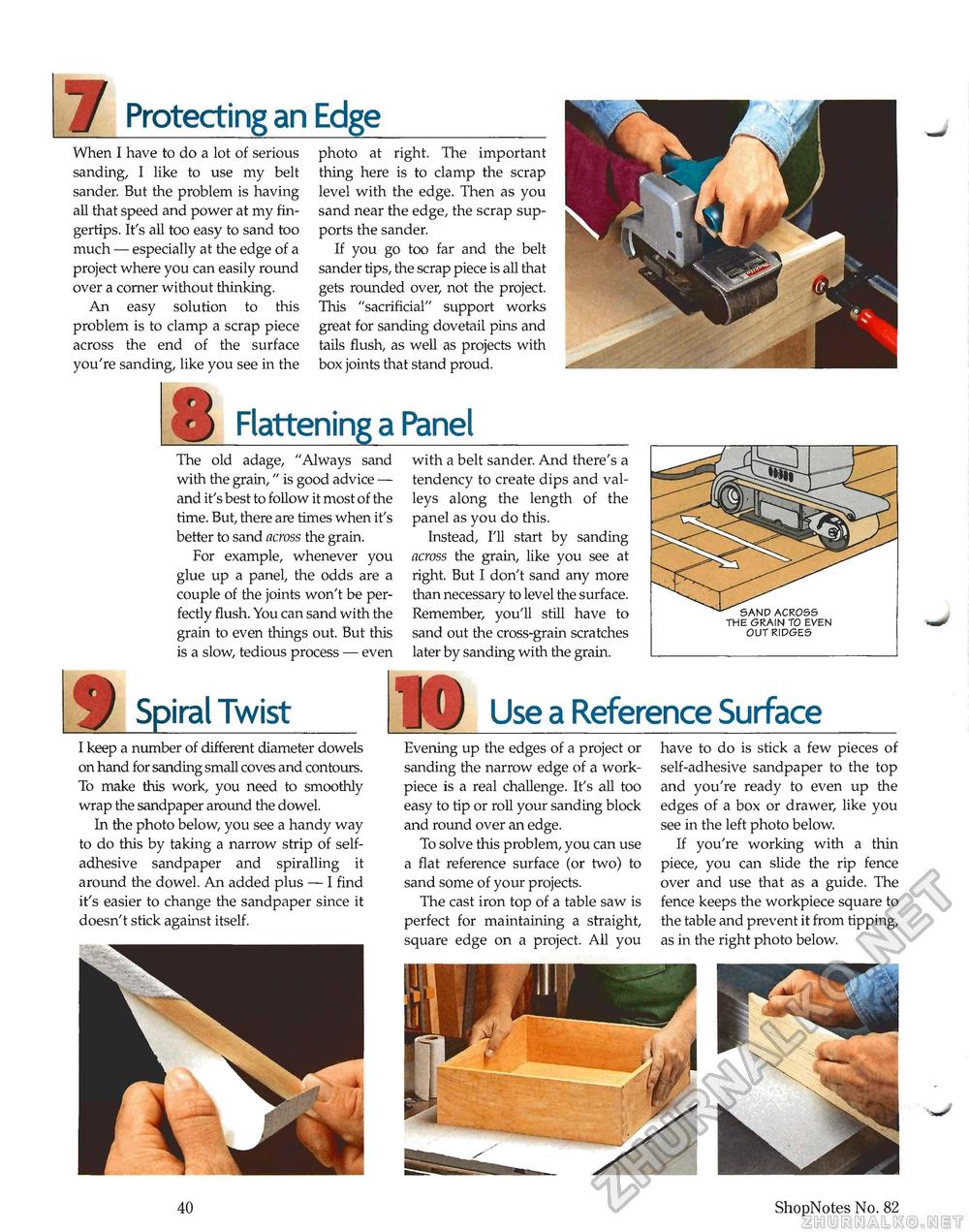

Protecting an Edge When I have to do a lot of serious sanding, I like to use my belt sander. But the problem is having all that speed and power at my fingertips. It's all too easy to sand too much — especially at the edge of a project where you can easily round over a corner without thinking. An easy solution to this problem is to clamp a scrap piece across the end of the surface you're sanding, like you see in the photo at right. The important thing here is to clamp the scrap level with the edge. Then as you sand near the edge, the scrap supports the sander. If you go too far and the belt sander tips, the scrap piece is all that gets rounded over, not the project. This "sacrificial" support works great for sanding dovetail pins and tails flush, as well as projects with box joints that stand proud. 13 Flattening a Panel The old adage, "Always sand with the grain," is good advice — and it's best to follow it most of the time. But, there are times when it's better to sand across the grain. For example, whenever you glue up a panel, the odds are a couple of the joints won't be perfectly flush. You can sand with the grain to even things out. But this is a slow, tedious process — even ^ Spiral Twist I keep a number of different diameter dowels on hand for sanding small coves and contours. To make this work, you need to smoothly wrap the sandpaper around the dowel. In the photo below, you see a handy way to do this by taking a narrow strip of self-adhesive sandpaper and spiralling it around the dowel. An added plus — I find it's easier to change the sandpaper since it doesn't stick against itself. with a belt sander. And there's a tendency to create dips and valleys along the length of the panel as you do this. Instead, I'll start by sanding across the grain, like you see at right. But I don't sand any more than necessary to level the surface. Remember, you'll still have to sand out the cross-grain scratches later by sanding with the grain. sand across the grain to even out ridges Use a Reference Surface Evening up the edges of a project or sanding the narrow edge of a work-piece is a real challenge. It's all too easy to tip or roll your sanding block and round over an edge. To solve this problem, you can use a flat reference surface (or two) to sand some of your projects. The cast iron top of a table saw is perfect for maintaining a straight, square edge on a project. All you have to do is stick a few pieces of self-adhesive sandpaper to the top and you're ready to even up the edges of a box or drawer, like you see in the left photo below. If you're working with a thin piece, you can slide the rip fence over and use that as a guide. The fence keeps the workpiece square to the table and prevent it from tipping, as in the right photo below. 40 ShopNotes No. 82 |