84, страница 13

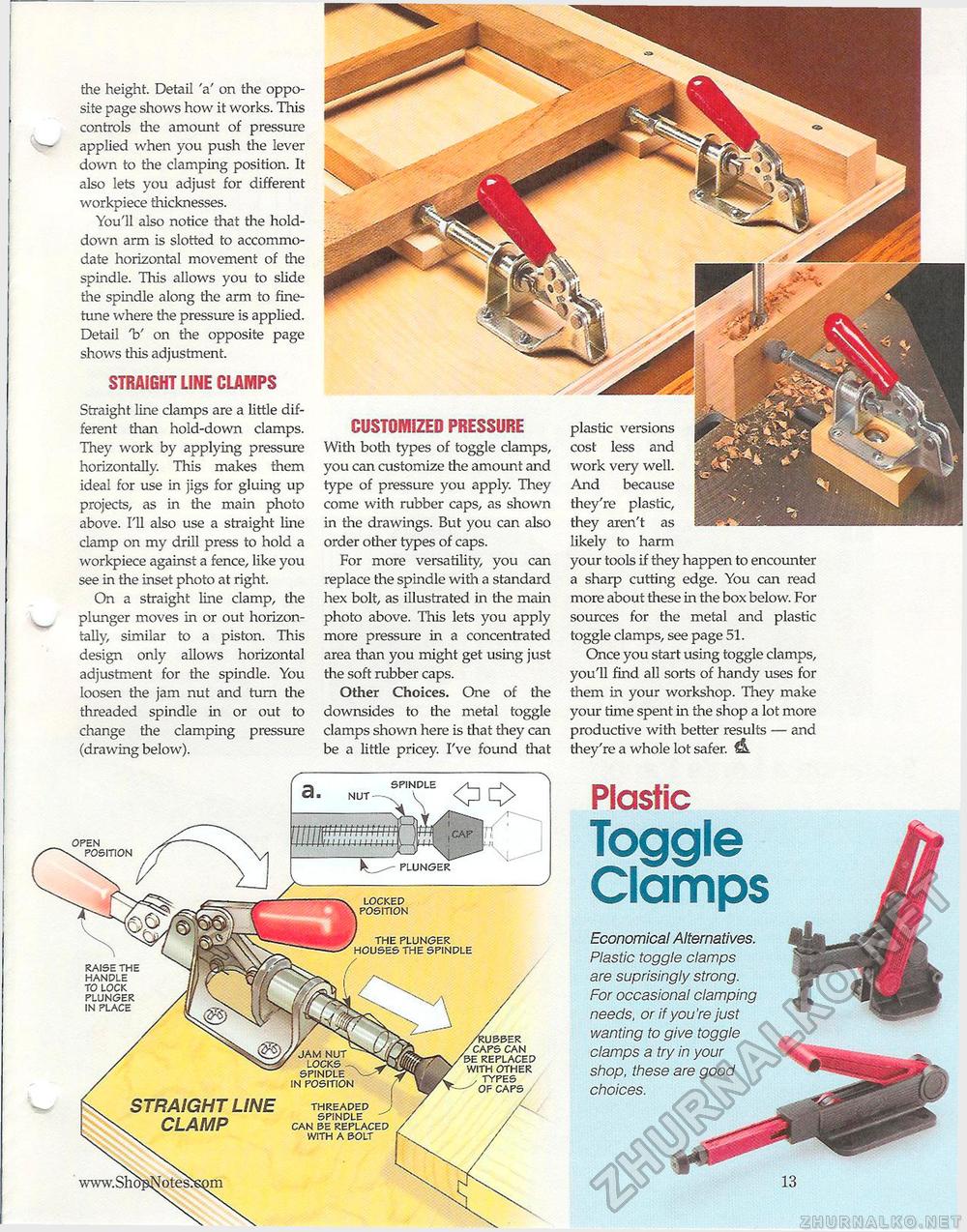

the height. Detail 'a' on the opposite page shows how it works. This controls the amount of pressure applied when you push the lever down to the clamping position. It also lets you adjust for different workpiece thicknesses. You'll also notice that the hold-down arm is slotted to accommodate horizontal movement of the spindle. This allows you to slide the spindle along the arm to fine-tune where the pressure is applied. Detail V on the opposite page shows this adjustment. STRAIGHT LINE CLAMPS Straight line clamps are a little different than hold-down clamps. They work by applying pressure horizontally. This makes them ideal for use in jigs for gluing up projects, as in the main photo above. I'll also use a straight line clamp on my drill press to hold a workpiece against a fence, like you see in the inset photo at right. On a straight line clamp, the plunger moves in or out horizontally, similar to a piston. This design only allows horizontal adjustment for the spindle. You loosen the jam nut and turn the threaded spindle in or out to change the clamping pressure (drawing below). CUSTOMIZED PRESSURE With both types of toggle clamps, you can customize the amount and type of pressure you apply. They come with rubber caps, as shown in the drawings. But you can also order other types of caps. For more versatility, you can replace the spindle with a standard hex bolt, as illustrated in the main photo above. This lets you apply more pressure in a concentrated area than you might get using just the soft rubber caps. Other Choices. One of the downsides to the metal toggle clamps shown here is that they can be a little pricey. I've found that plastic versions cost less and work very well. And because they're plastic, they aren't as likely to harm your tools if they happen to encounter a sharp cutting edge. You can read more about these in the box below. For sources for the metal and plastic toggle clamps, see page 51. Once you start using toggle clamps, you'll find all sorts of handy uses for them in your workshop. They make your time spent in the shop a lot more productive with better results — and they're a whole lot safer. OPEN . POSITION /JAM NUT LOCKS SPINDLE IN POSITION STRAIGHT LINE CLAMP THREADED SPINDLE CAN BE REPLACED WITH A BOLT www.ShopNotes>som r oc> ■ - PLUNGER LOCKED POSITION Wy THE PLUNGER --HOUSES THE SPINDLE RAISE THE HANDLE TO LOCK IN PLACE LIBBER CAPS CAN BE REPLACED WITH OTHER TYPES OF CAPS Plastic Toggle Clamps Economical Alternatives. Plastic toggle clamps are suprisingly strong. For occasional clamping needs, or if you're just wanting to give toggle clamps a try in your shop, these are good choices. |