84, страница 18

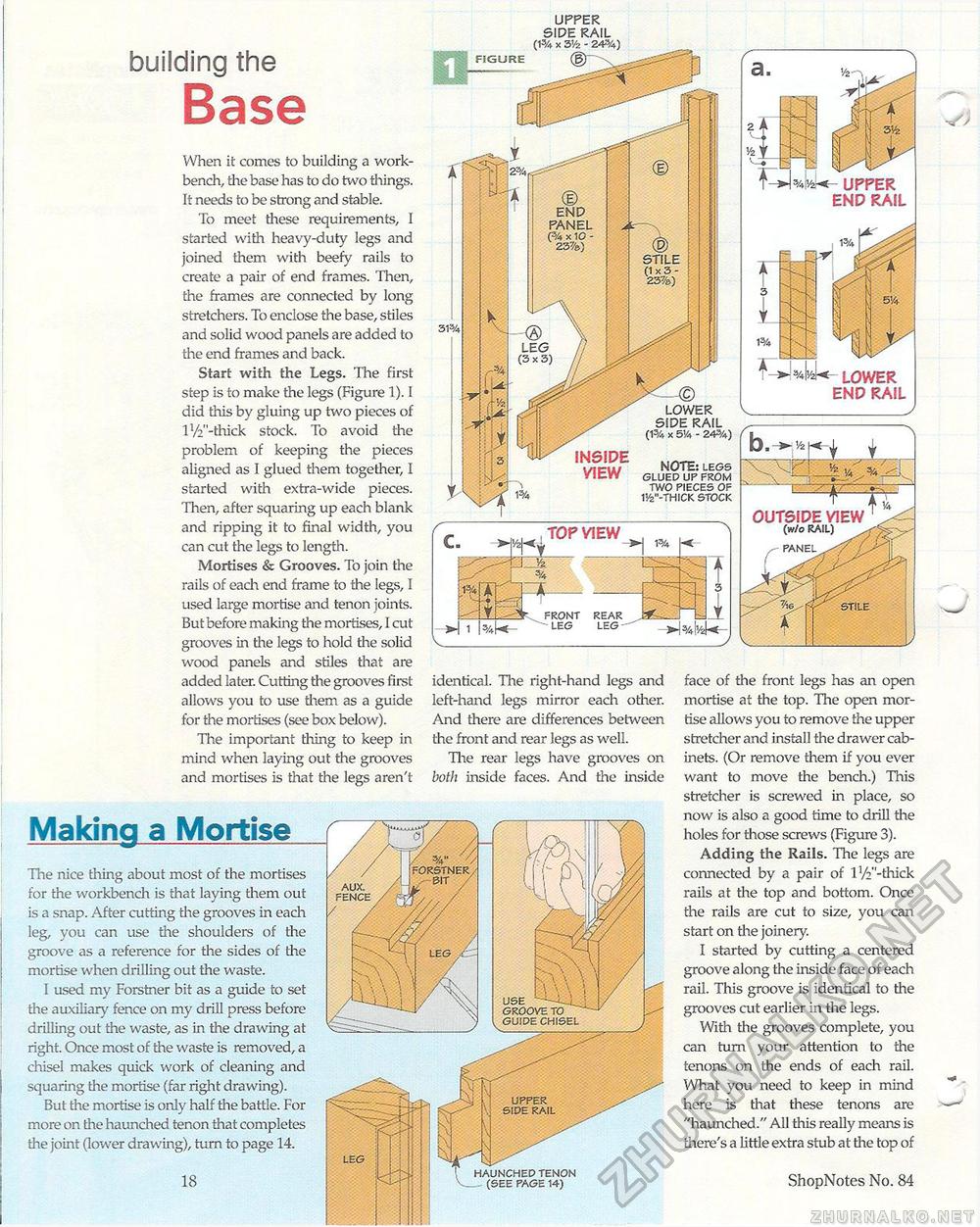

building the Base The nice thing about most of the mortises for the workbench is that laying them out is a snap. After cutting the grooves in each leg, you can use the shoulders of the groove as a reference for the sides of the mortise when drilling out the waste. I used my Forstner bit as a guide to set the auxiliary fence on my drill press before drilling out the waste, as in the drawing at right. Once most of the waste is removed, a chisel makes quick work of cleaning and squaring the mortise (far right drawing). But the mortise is only half the battle. For more on the haunched tenon that completes the joint (lower drawing), turn to page 14. 18 UPPER END RAIL When it comes to building a workbench, the base has to do two things. It needs to be strong and stable. To meet these requirements, I started with heavy-duty legs and joined them with beefy rails to create a pair of end frames. Then, the frames are connected by long stretchers. To enclose the base, stiles and solid wood panels are added to the end frames and back. Start with the Legs. The first step is to make the legs (Figure 1). I did this by gluing up two pieces of iy2"-thick stock. To avoid the problem of keeping the pieces aligned as I glued them together, I started with extra-wide pieces. Then, after squaring up each blank and ripping it to final width, you can cut the legs to length. Mortises & Grooves. To join the rails of each end frame to the legs, I used large mortise and tenon joints. But before making the mortises, I cut grooves in the legs to hold the solid wood panels and stiles that are added later. Cutting the grooves first allows you to use them as a guide for the mortises (see box below). The important tiling to keep in mind when laying out the grooves and mortises is that the legs aren't Making a Mortise identical. The right-hand legs and left-hand legs mirror each other. And there are differences between the front and rear legs as well. Hie rear legs have grooves on both inside faces. And the inside face of the front legs has an open mortise at the top. The open mortise allows you to remove the upper stretcher and install the drawer cabinets. (Or remove them if you ever want to move the bench.) This stretcher is screwed in place, so now is also a good time to drill the holes for those screws (Figure 3). Adding the Rails. The legs are connected by a pair of 1 '/V'-thick rails at the top and bottom. Once the rails are cut to size, you can start on the joiner)'. I started by cutting a centered groove along the inside face of each rail. This groove is identical to the grooves cut earlier in the legs. With the grooves complete, you can turn your attention to the tenons on the ends of each rail. What you need to keep in mind here is that these tenons are "haunched." All this really means is there's a little extra stub at Hie top of ShopNotes No. 84 TOP VIEW LOWER END RAIL upper side rail (1% X SVz - 24%) OUTSIDE VIEW (w/o RAIL) front rear leg leg INSIDE VIEW lower side rail (1% x 5% - 24%) NOTE: legs glued up from two pieces of 11/2"-thick stock |