86, страница 20

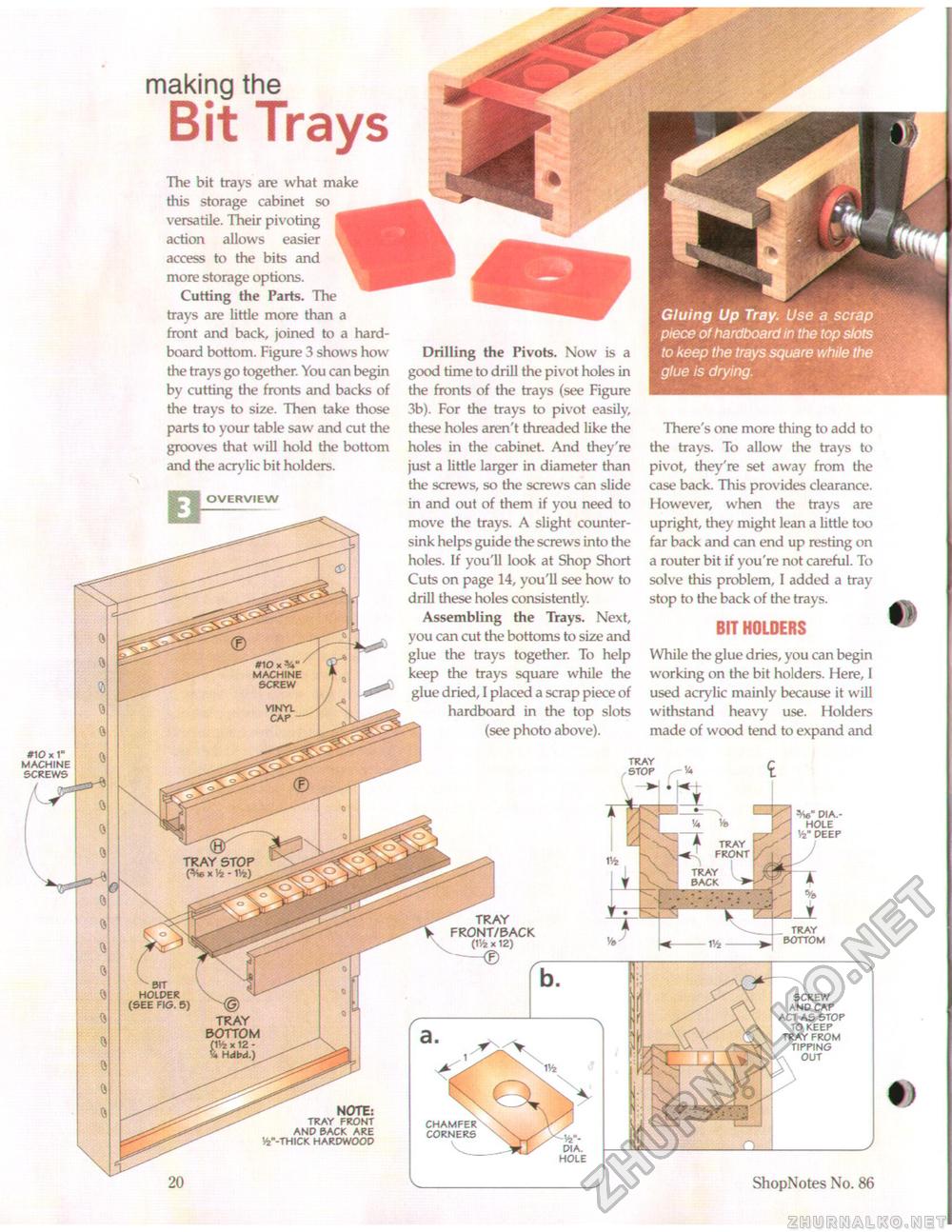

making the Bit Trays The bit trays are what make this storage cabinet so versatile. Their pivoting action allows easier access to the bits and more storage options. Cutting the Parts. The trays are little more than a front and back, joined to a hard-board bottom. Figure 3 shows how the trays go together. You can begin by cutting the fronts and backs of the trays to size. Then take those parts to your table saw and cut the grooves that will hold the bottom and the acrylic bit holders. OVERVIEW Drilling the Pivots. Now is a good time to drill the pivot holes in the fronts of the trays (see Figure 3b). For the trays to pivot easily, these holes aren't threaded like the holes in the cabinet. And they're just a little larger in diameter than the screws, so the screws can slide in and out of them if you need to move the trays. A slight countersink helps guide the screws into the holes. If you'll look at Shop Short Cuts on page 14, you'll see how to drill these holes consistently. Assembling the Trays. Next, you can cut the bottoms to size and glue the trays together. To help keep the trays square while the glue dried, I placed a scrap piece of hardboard in the top slots (see photo above). There's one more thing to add to the trays. To allow the trays to pivot, they're set away from the case back. This provides clearance. However, when the trays are upright, they might lean a little too far back and can end up resting on a router bit if you're not careful. To solve this problem, I added a tray stop to the back of the trays. BIT HOLDERS While the glue dries, you can begin working on the bit holders. Here, I used acrylic mainly because it will withstand heavy use. Holders made of wood tend to expand and ✓ TRAY FRONT/BACK (IVfe x 12) I I vj» | £ tray V-/- tray i v < pack ''^ggggKBI- 3ae" dia.-hole w deep ) A. NOTE: tray front and back are "-thick hardwood tray bottom screw and cap act as stop to keep tray from tipping - out 20 ShopNotes No. 86 |