90 - Get the Most out of a Plunge Router, страница 12

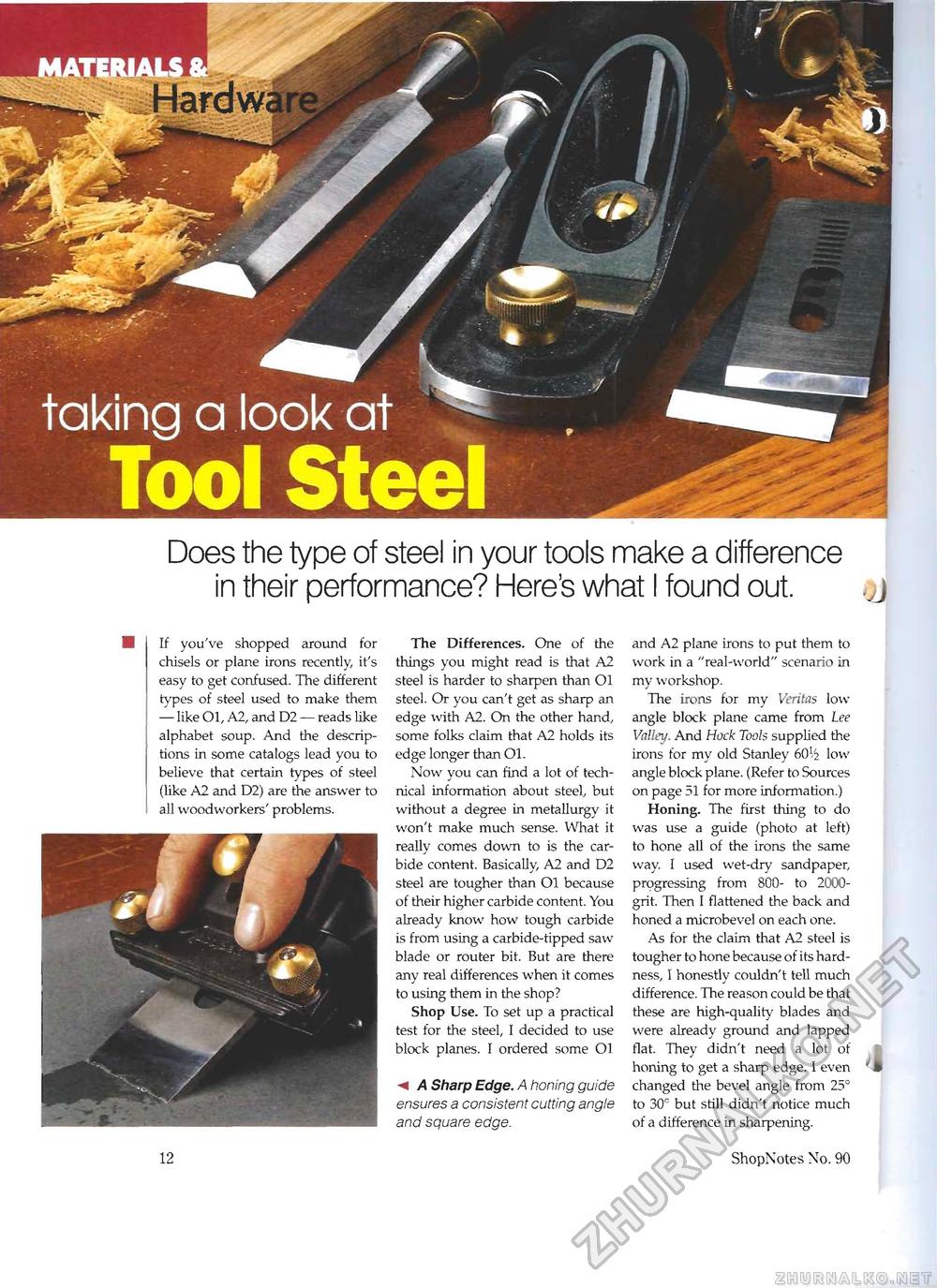

HarcJw Does the type of steel in your tools make a difference in their performance? Here's what I found out. j If you've shopped around for chisels or plane irons recently, it's easy to get confused. The different types of steel used to make them — like Ol, A2, and D2 — reads like alphabet soup. And the descriptions in some catalogs lead you to believe that certain types of steel (like A2 and D2) are the answer to all woodworkers' problems. The Differences. One of the things you might read is that A2 steel is harder to sharpen than Ol steel. Or you can't get as sharp an edge with A2. On the other hand, some folks claim that A2 holds its edge longer than Ol. Now you can find a lot of technical information about steel, but without a degree in metallurgy it won't make much sense. What it really comes down to is the carbide content. Basically, A2 and D2 steel are tougher than Ol because of their higher carbide content. You already know how tough carbide is from using a carbide-tipped saw blade or router bit. But are there any real differences when it comes to using them in the shop? Shop Use. To set up a practical test for the steel, I decided to use block planes. I ordered some Ol A Sharp Edge. honing guide ensures a consistent cutting angle and square edge. and A2 plane irons to put them to work in a "real-world" scenario in my workshop. The irons for my Veritas low angle block plane came from Lee Valley. And Hock Tools supplied the irons for my old Stanley 60low angle block plane. (Refer to Sources on page 51 for more information.) Honing. The first thing to do was use a guide (photo at left) to hone all of the irons the same way. I used wet-dry sandpaper, progressing from 800- to 2000-grit. Then I flattened the back and honed a microbevel on each one. As for the claim that A2 steel is tougher to hone because of its hardness, I honestly couldn't tell much difference. The reason could be that these are high-quality blades and were already ground and lapped flat. They didn't need a lot of honing to get a sharp edge. I even 1 $ changed the bevel angle from 25° to 30c but still didn't notice much of a difference in sharpening. 12 ShopNotes No. 90 |