90 - Get the Most out of a Plunge Router, страница 13

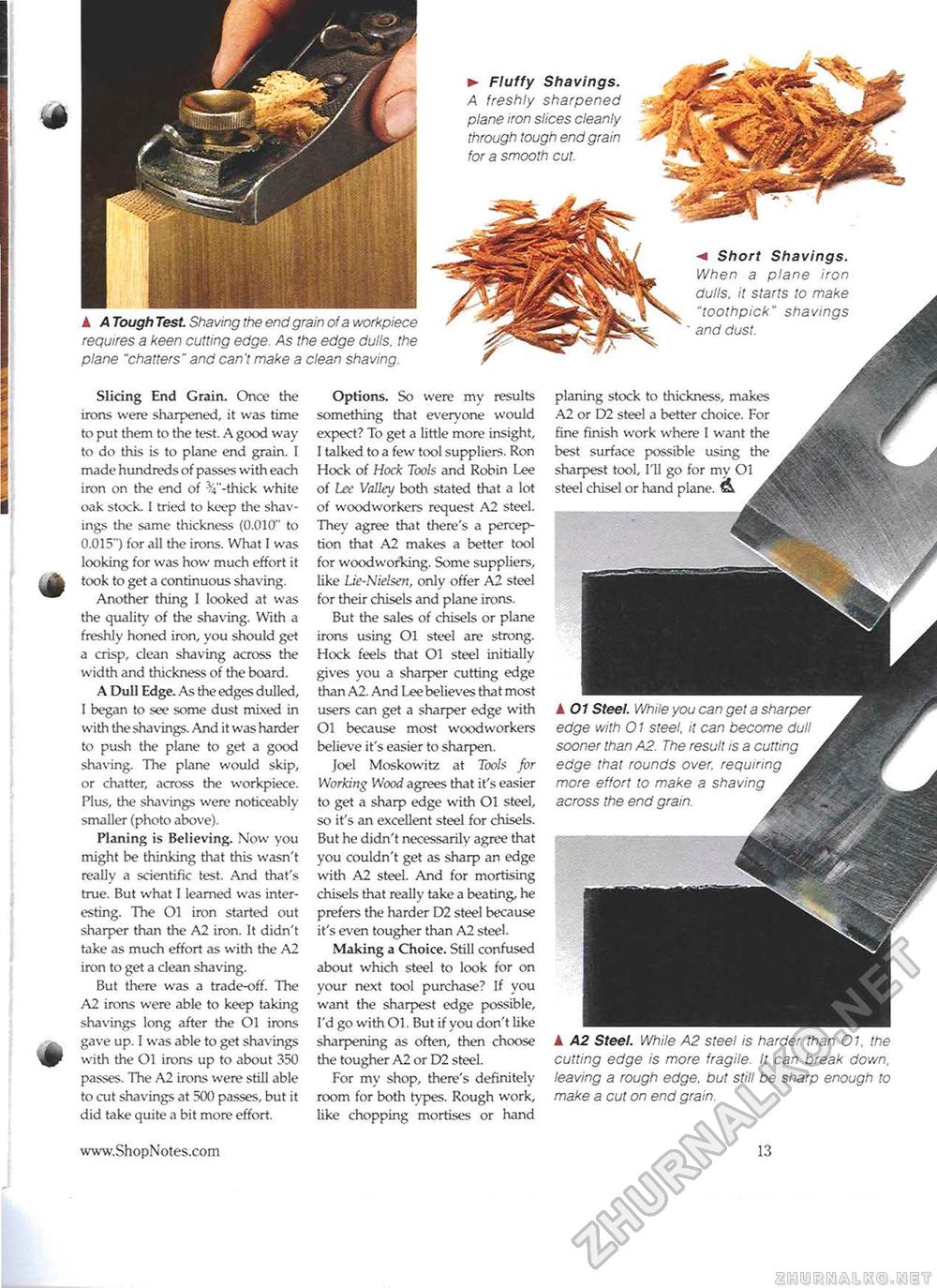

* Short Shavings. When a plane iron dulls, it starts to make "toothpick" shavings and dust. planing stock to thickness, makes A2 or D2 steel a better choice. For fine finish work where I want the best surface possible using the sharpest tool, I'll go for my Ol steel chisel or hand plane. Ok v :■; ' - ■ . ■■■ ► Fluffy Shavings. A freshly sharpened plane iron slices cleanly through tough end grain for a smooth cut. A A Tough Test. Shaving the end grain of a workpiece requires a keen cutting edge As the edge dulls, the plane "chatters" and can't make a clean shaving. Slicing End Grain. Once the irons were sharpened, it was time to put them to the test. A good way to do this is to plane end grain. I made hundreds of passes with each iron on the end of V-thick white oak stock. I tried to keep the shavings the same thickness (0.010" to 0.015") for all the irons. What I was looking for was how much effort it took to get a continuous shaving. Another thing I looked at was the quality of the shaving. With a freshly honed iron, you should get a crisp, clean shaving across the width and thickness of the board. A Dull Edge. As the edges dulled, 1 began to see some dust mixed in with the shavings. And it was harder to push the plane to get a good shaving. The plane would skip, or chatter, across the workpiece. Plus, the shavings were noticeably smaller (photo above). Planing is Believing. Now you might be thinking that this wasn't really a scientific test. And that's true. But what I learned was interesting. The Ol iron started out sharper than the A2 iron. It didn't take as much effort as with the A2 iron to get a clean shaving. But there was a trade-off. The A2 irons were able to keep taking shavings long after the Ol irons gave up. I was able to get shavings with the Ol irons up to about 350 passes. The A2 irons were still able to ait shavings at 500 passes, but it did take quite a bit more effort. Options. So were my results something that everyone would expect? To get a little more insight, I talked to a few tool suppliers. Ron Hock of Hock Tools and Robin Lee of Lee Valley both stated that a lot of woodworkers request A2 steel. They agree that there's a perception that A2 makes a better tool for woodworking. Some suppliers, like Lie-Nielsen, only offer A2 steel for their chisels and plane irons. But the sales of chisels or plane irons using Ol steel are strong. Hock feels that Ol steel initially gives you a sharper cutting edge than A2. And Lee believes that most users can get a sharper edge with Ol because most woodworkers believe it's easier to sharpen. Joel Moskowitz at Tools far Working Wood agrees that it's easier to get a sharp edge with Ol steel, so it's an excellent steel for chisels. But he didn't necessarily agree that you couldn't get as sharp an edge with A2 steel. And for mortising chisels that really take a beating, he prefers the harder D2 steel because it's even tougher than A2 steel. Making a Choice. Still confused about which steel to look for on your next tool purchase? If you want the sharpest edge possible, I'd go with Ol. But if you don't like sharpening as often, then choose the tougher A2 or D2 steel. For my shop, there's definitely room for both types. Rough work, like chopping mortises or hand A A2 Steel. While A2 steel is harder than 01. the cutting edge is more fragile. It can break down, leaving a rough edge, but still be sharp enough to make a cut on end grain. kOI Steel. While you can get a sharper edge with Ol steel, it can become dull sooner than A2. The result is a cutting edge that rounds over, requiring more effort to make a shaving across the end grain. |