91 - Planer Stand, страница 45

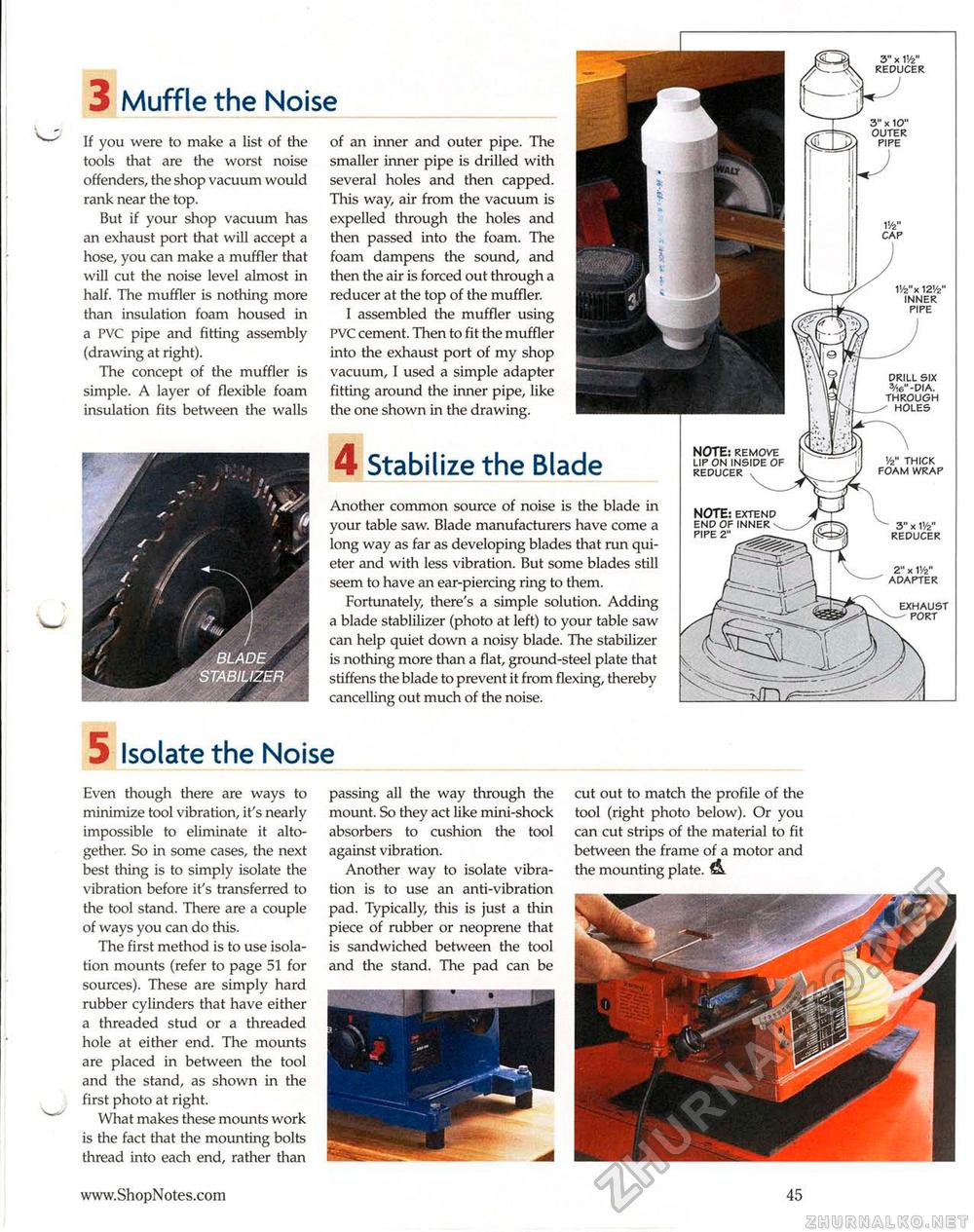

cut out to match the profile of the tool (right photo below). Or you can cut strips of the material to fit between the frame of a motor and the mounting plate. & 5 Isolate the Noise Even though there are ways to minimize tool vibration, it's nearly impossible to eliminate it altogether. So in some cases, the next best thing is to simply isolate the vibration before it's transferred to the tool stand. There are a couple of ways you can do this. The first method is to use isolation mounts (refer to page 51 for sources). These are simply hard rubber cylinders that have either a threaded stud or a threaded hole at either end. The mounts are placed in between the tool and the stand, as shown in the first photo at right. What makes these mounts work is the fact that the mounting bolts thread into each end, rather than passing all the way through the mount. So they act like mini-shock absorbers to cushion the tool against vibration. Another way to isolate vibration is to use an anti-vibration pad. Typically, this is just a thin piece of rubber or neoprene that is sandwiched between the tool and the stand. The pad can be NOTE: remove lip on inside of reducer NOTE: extend end of inner pipe 2" 3 Muffle the Noise 3" x 1VS" reducer 3" x 10" outer pipe 1'/2"x 12'/2" inner pipe drill six 3/i6"-dia. through holes w thick foam wrap 3" x 1)4" reducer 2" x V/z" adapter If you were to make a list of the tools that are the worst noise offenders, the shop vacuum would rank near the top. But if your shop vacuum has an exhaust port that will accept a hose, you can make a muffler that will cut the noise level almost in half. The muffler is nothing more than insulation foam housed in a PVC pipe and fitting assembly (drawing at right). The concept of the muffler is simple. A layer of flexible foam insulation fits between the walls of an inner and outer pipe. The smaller inner pipe is drilled with several holes and then capped. This way, air from the vacuum is expelled through the holes and then passed into the foam. The foam dampens the sound, and then the air is forced out through a reducer at the top of the muffler. I assembled the muffler using PVC cement. Then to fit the muffler into the exhaust port of my shop vacuum, I used a simple adapter fitting around the inner pipe, like the one shown in the drawing. 4 Stabilize the Blade Another common source of noise is the blade in your table saw. Blade manufacturers have come a long way as far as developing blades that run quieter and with less vibration. But some blades still seem to have an ear-piercing ring to them. Fortunately, there's a simple solution. Adding a blade stablilizer (photo at left) to your table saw can help quiet down a noisy blade. The stabilizer is nothing more than a flat, ground-steel plate that stiffens the blade to prevent it from flexing, thereby cancelling out much of the noise. 45 |