91 - Planer Stand, страница 44

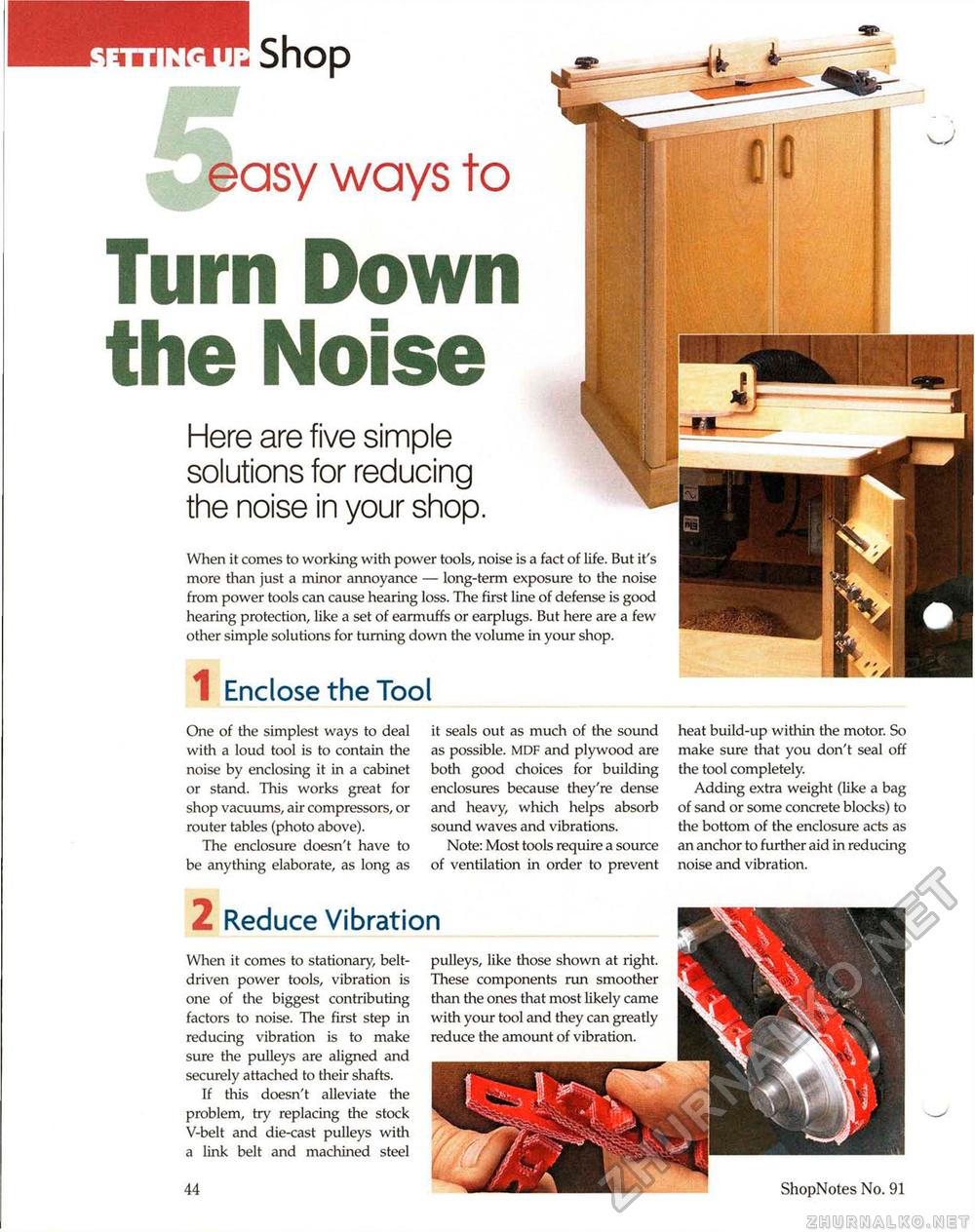

When it comes to working with power tools, noise is a fact of life. But it's more than just a minor annoyance — long-term exposure to the noise from power tools can cause hearing loss. The first line of defense is good hearing protection, like a set of earmuffs or earplugs. But here are a few other simple solutions for turning down the volume in your shop. 1 Enclose the Tool i easy ways to Turn Down the NoiseHere are five simple solutions for reducing the noise in your shop. One of the simplest ways to deal with a loud tool is to contain the noise by enclosing it in a cabinet or stand. This works great for shop vacuums, air compressors, or router tables (photo above). The enclosure doesn't have to be anything elaborate, as long as it seals out as much of the sound as possible. MDF and plywood are both good choices for building enclosures because they're dense and heavy, which helps absorb sound waves and vibrations. Note: Most tools require a source of ventilation in order to prevent heat build-up within the motor. So make sure that you don't seal off the tool completely. Adding extra weight (like a bag of sand or some concrete blocks) to the bottom of the enclosure acts as an anchor to further aid in reducing noise and vibration. 2 Reduce Vibration ShopNotes No. 91 When it comes to stationary, belt-driven power tools, vibration is one of the biggest contributing factors to noise. The first step in reducing vibration is to make sure the pulleys are aligned and securely attached to their shafts. If this doesn't alleviate the problem, try replacing the stock V-belt and die-cast pulleys with a link belt and machined steel 44 pulleys, like those shown at right. These components run smoother than the ones that most likely came with your tool and they can greatly reduce the amount of vibration. |