Woodworker's Journal 1983-7-3, страница 26

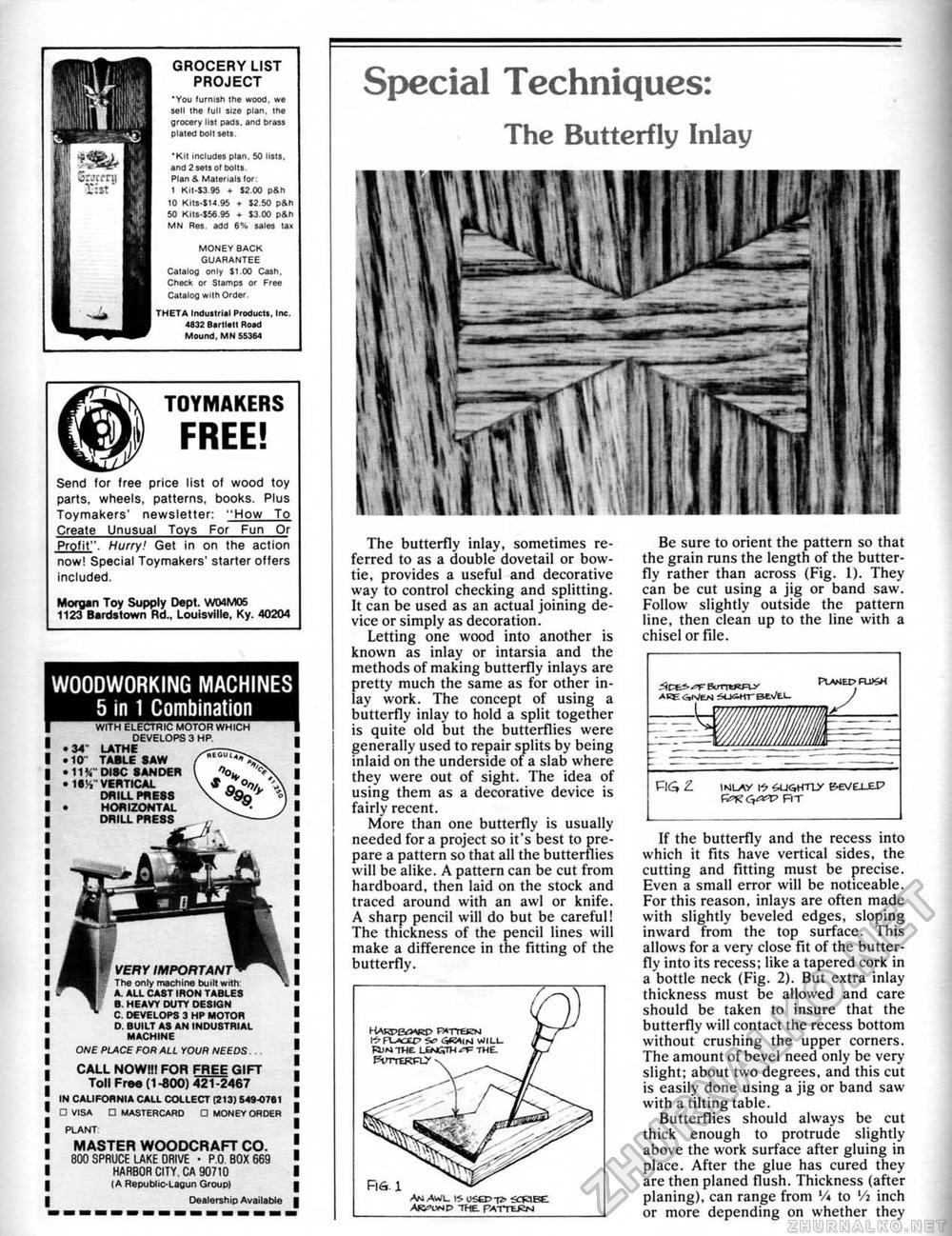

WOODWORKING MACHINES 5 in 1 Combination Profit". Hurry! Get in on the action now! Special Toymakers* starter offers included. Morgan Toy Supply Dept. W04MC6 1123 Bardstown Rd.. Louisville, Ky. 40204 FIG i- IHL^Y ^U<JHTLy &ev£iJEP FBT GROCERY LIST PROJECT 'You furnish (ho wood, we sell the full size plan, the grocery list pads, and brass plated bolt sets 'Kit includes plan. 50 lists, and 2 sets of bolts, Plan & Materials lor: 1 KI1-S3.95 ♦ $2.00 p&h 10 Kila-514.95 + 12,50 p&h 50 Kils-156,95 + S3,00 p&h MM Res add 6% sales ta* MONEY SACK GUARANTEE Catalog only Si,00 Cash, Check or Stamps or Free Catalog will* Order THETA Industrial Products, Inc. 4832 Bartlatt Road Mound, MN 55364 TOYMAKERS FREE! Send for free price list of wood toy parts, wheels, patterns, books. Plus Toymakers' newsletter: "How To Create Unusual Toys For Fun Or WITH ELECTS !C MOTOR WHICH DEVELOPS 3 HP <34" LATHE • 10" TABLE SAW • 11*" DISC SANDER • 1IS" VERTICAL DRILL PRESS • HORIZONTAL DRILL PRESS Special Techniques: The Butterfly Inlay CALL NOWIIl FOR FREE GIFT Toll Free (1-SOO) 421-2467 IN CALIFORNIA CALL COLLECT (213) 549-0761 □ VISA □ MASTERCARD □ WONEV ORDER PLANT MASTER WOODCRAFT CO. 800 SPRUCE LAKE DRIVE ■ P 0 BOX 669 HARBOR CITY CA 90710 IA Republic-Lagun Group] Dealership Available The butterfly inlay, sometimes referred to as a double dovetail or bow-tie, provides a useful and decorative way to control checking and splitting. It can be used as an actual joining device or simply as decoration. Letting one wood into another is known as inlay or intarsia and the methods of making butterfly inlays are pretty much the same as for other inlay work. The concept of using a butterfly inlay to hold a split together is quite old but the butterflies were generally used to repair splits by being inlaid on the underside of a slab where they were out of sight. The idea of using them as a decorative device is fairly recent. More than one butterfly is usually needed for a project so it's best to prepare a pattern so that all the butterflies will be alike. A pattern can be cut from hardboard, then laid on the stock and traced around with an awl or knife. A sharp pencil will do but be careful! The thickness of the pencil lines will make a difference in the fitting of the butterfly. DESIGN C. DEVELOPS 3 HP MOTOR D. BUILT AS AN INDUSTRIAL MACHINE ONE PLACE FOR ALL YOUR NEEDS. If the butterfly and the recess into which it fits have vertical sides, the cutting and fitting must be precise. Even a small error will be noticeable. For this reason, inlays are often made with slightly beveled edges, sloping inward from the top surface. This allows for a very close fit of the butterfly into its recess; like a tapered cork in a bottle neck (Fig. 2). But extra inlay thickness must be allowed and care should be taken to insure that the butterfly will contact the recess bottom without crushing the upper corners. The amount of bevel need only be very-slight; about two degrees, and this cut is easily done using a jig or band saw with a tilting table. Butterflies should always be cut thick enough to protrude slightly above the work surface after gluing in place. After the glue has cured they are then planed flush. Thickness (after planing), can range from V* to Vi inch or more depending on whether they Be sure to orient the pattern so that the grain runs the length of the butterfly rather than across {Fig. 1). They can be cut using a jig or band saw. Follow slightly outside the pattern line, then clean up to the line with a chisel or file. F|6.1 AN/IWL. I-S usep-p. snEtBEi AKi?VHt> THE- nvrrtjeN Hweuwp wntuN Fuctp Sf rj wi LU ftjM "THE LEN&TH --"F THE. EHfTYEKPO' |