Woodworker's Journal 1985-9-3, страница 18

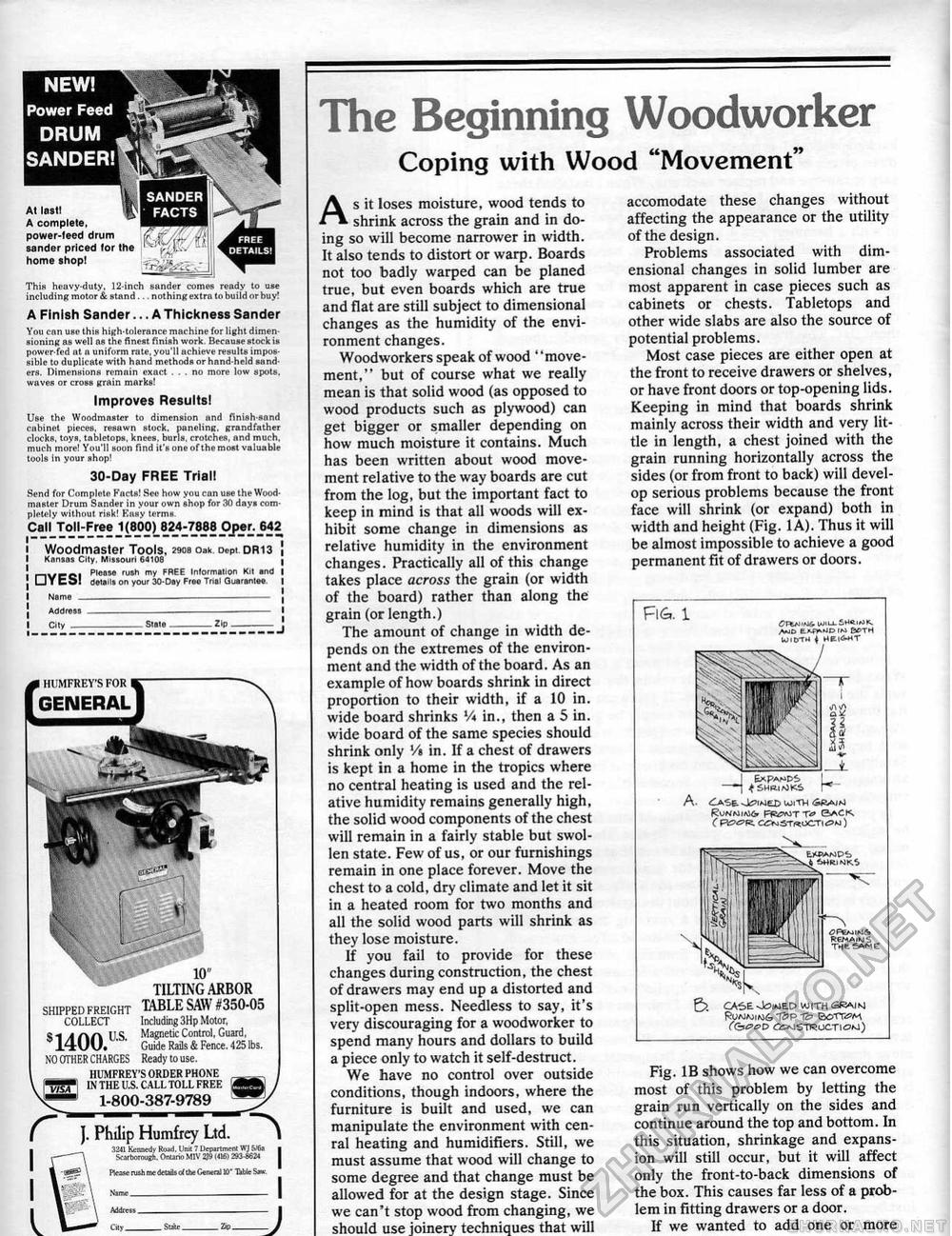

At last! A complete, power-leed drum sander priced for the home shop! This heavy-duty, 12-inch sander comes ready to use including motor & stand ... nothing extra to build or buy! A Finish Sander... A Thickness Sander You CHn use this high-tolerance machine for light dimensioning as well as the finest finish work. Because stock is power-fed at u uniform rate, you'll achieve results impossible to duplicate with hand methods or hand-held sanders, Dimensions remain exact ... no more low apots. waves or cross grain marks! Improves Results! Use the Woodmastcr to dimension and finish-sand cabinet pieces, resawn stock, paneling, grandfather clocks, toys, tabletops, knees, burls, crotches, and much, much more! You'll soon find it's one of the most valuable tools in your shop! 30-Day FREE Trialt Send for Complete Facts! See how you can use the Wood-master Drum Sander in your own shop for 30 days completely without risk! Eusy terms. Call Toil-Free J [800)_B2jl-7888 0per.^42 Woodmaster Tools, 2^00 oak oept DR13 Kansas City, Missouri 64108 nx/__. Please rush my FREE Information Kil and LJY tb! detain on your 30-Day Frae Trial Guarantee. Address City State wiiy .--H ---j Zip . The Beginning Woodworker Coping with Wood "Movement" As it loses moisture, wood tends to shrink across the grain and in doing so will become narrower in width. It also tends to distort or warp. Boards not too badly warped can be planed true, but even boards which are true and flat are still subject to dimensional changes as the humidity of the environment changes. Woodworkers speak of wood "movement," but of course what we really mean is that solid wood (as opposed to wood products such as plywood) can get bigger or smaller depending on how much moisture it contains. Much has been written about wood movement relative to the way boards are cut from the log, but the important fact to keep in mind is that all woods will exhibit some change in dimensions as relative humidity in the environment changes. Practically all of this change takes place across the grain (or width of the board) rather than along the grain (or length.) The amount of change in width depends on the extremes of the environment and the width of the board. As an example of how boards shrink in direct proportion to their width, if a 10 in. wide board shrinks V* in., then a 5 in. wide board of the same species should shrink only '/> in. If a chest of drawers is kept in a home in the tropics where no central heating is used and the relative humidity remains generally high, the solid wood components of the chest will remain in a fairly stable but swollen state. Few of us, or our furnishings remain in one place forever. Move the chest to a cold, dry climate and let it sit in a heated room for two months and all the solid wood parts will shrink as they lose moisture. If you fail to provide for these changes during construction, the chest of drawers may end up a distorted and split-open mess. Needless to say, it's very discouraging for a woodworker to spend many hours and dollars to build a piece only to watch it self-destruct. We have no control over outside conditions, though indoors, where the furniture is built and used, we can manipulate the environment with cen-ral heating and humidifiers. Still, we must assume that wood will change to some degree and that change must be allowed for at the design stage. Since we can't stop wood from changing, we should use joinery techniques that will accomodate these changes without affecting the appearance or the utility of the design. Problems associated with dimensional changes in solid lumber are most apparent in case pieces such as cabinets or chests. Tabletops and other wide slabs are also the source of potential problems. Most case pieces are either open at the front to receive drawers or shelves, or have front doors or top-opening lids. Keeping in mind that boards shrink mainly across their width and very little in length, a chest joined with the grain running horizontally across the sides (or from front to back) will develop serious problems because the front face will shrink (or expand) both in width and height (Fig. 1A). Thus it will be almost impossible to achieve a good permanent fit of drawers or doors. Fig. IB shows how we can overcome most of this problem by letting the grain run vertically on the sides and continue around the top and bottom. In this situation, shrinkage and expansion will still occur, but it will affect only the front-to-back dimensions of the box. This causes far less of a problem in fitting drawers or a door. If we wanted to add one or more 10" TILTING .ARBOR TABLE SAW #350-05 Including 3Hp Motor, Magnetic Control, Guard, Guide Rails & Fence. 425 lbs. Ready to use. r }. Philip Humfrey Ltd. ^ I I Address _____I City_State__ Zip- E 32J1 Kennedy Road. Unit 7 Department WJ StfiB Scarborough, Ontario M1V 2)9 (416) 293-S624 Please- rush me details of the General 10" Table Saw. SHIPPED FREIGHT COLLECT S1400.LS SO OTHER CHARGES THEMME £>, CA5£0OWE.D with <33*1 SJ TOP To Bottom. (CoviSTCOCTlCW) EXPAMPS •f SHRINKS A. JcrWET) UilTW KvNHinb T" e^iCi*. ( PWR aSfciS-rwUCTl C5M ) CT**1 tU< LL SHft I« fc. /V..t^^lD rW f^'TH wio-rrt i |