Woodworker's Journal 1993-17-1, страница 51

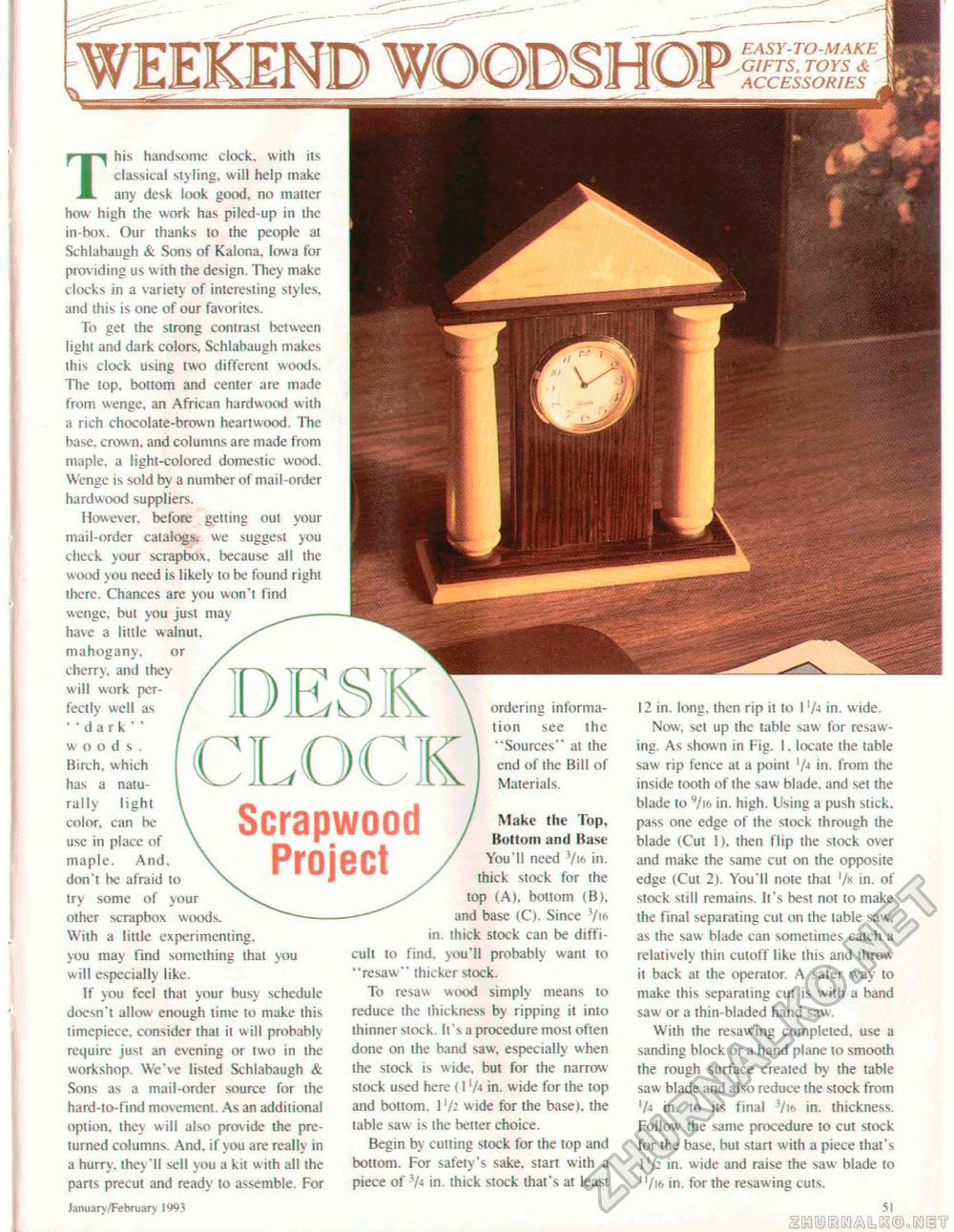

This handsome clock, with its classical styling, will help make any desk look good, no matter how high the work has piled-up in the in-bo\. Our thanks lo ihe people at Schlabaugh &. Sons of Kalona, Iowa lor providing us with the design. They make clocks in a variety of interesting styles, and this is one of our favorites. To get the strong contrast between light and dark colors. Schlabaugh makes this clock using two different woods. The top. bottom and center are made from wenge, an African hardwood with a rich chocolate-brown heartwood. The base, crow n, and columns are made from maple, a light-colored domestic wood. Wenge is sold by a number of mail-order hardwood suppliers. However, before getting out your mail-order catalogs, we suggest you check your scrapbox, because all the wood you need is likely 10 be found right ihere. Chances are you won't find wenge. but you just may have a little walnut, mahogany, or cherry, and they will work perfectly well as "dark" woods. Birch, which has a naturally light color, can be use in place of maple. And, don't be afraid to try some of your other scrapbox woods. With a little experimenting, you may find something that you will especially like. If you feel that your busy schedule doesn't allow enough time to make this timepiece, consider that it will probably require just an evening or two in the workshop. We've listed Schlabaugh & Sons as a mail-order source for the hard-to-find movement. As an additional option, they will also provide the pre-turned columns. And. if you are really in a hurry, they'll sell you a kit with all the parts precut and ready to assemble. For 12 in. long, then rip it to 1 '/■» in. wide. Now. set up the table saw for resawing. As shown in Fig. I. locate the table saw rip fence at a point '/■> in. from the inside tooth of the saw blade, and set the blade to w/to in. high. Using a push stick, pass one edge of the stock through the blade (Cut 1). then flip the stock over and make the same cut on the opposite edge (Cut 2). You'll note that '/* in. of stock still remains. It's best not to make ihe final separating cul on the table saw. as the saw blade can sometimes catch a relatively thin cutoff like this and throw it back at the operator. A safer way to make this separating cut is with a band saw or a thin-bladed hand saw. With the resawing completed, use a sanding block or a hand plane to smooth the rough surface created by the table saw blade and also reduce the stock from '/4 in. to its final 3/» in. thickness. Follow the same procedure to cut stock for the base, but start with a piece that's 1'/^ in. wide and raise the saw blade to "M in. for the resawing cuts. ordering information see the "Sources" al the end of the Bill of Materials. Make the Top, Bottom and Base You'll need Vig in. thick stock for the top (A), bottom (B), and base (C). Since Vto in. thick stock can be difficult to find, you'll probably want to "resaw" thicker stock. To resaw wood simply means to reduce the thickness by ripping it into thinner stock. It's a procedure most often done on the band saw. especially when the stock is wide, but for the narrow stock used here < 1 'A in. wide for Ihe top and bottom. 1'/- w ide for the base), the table saw is the better choice. Begin by cutting stock for the top and bottom. For safety's sake, start with a piece of -7<s in. thick stock that's at least Januarv/Februar\ 1993 51 |