Woodworker's Journal 1993-17-1, страница 52

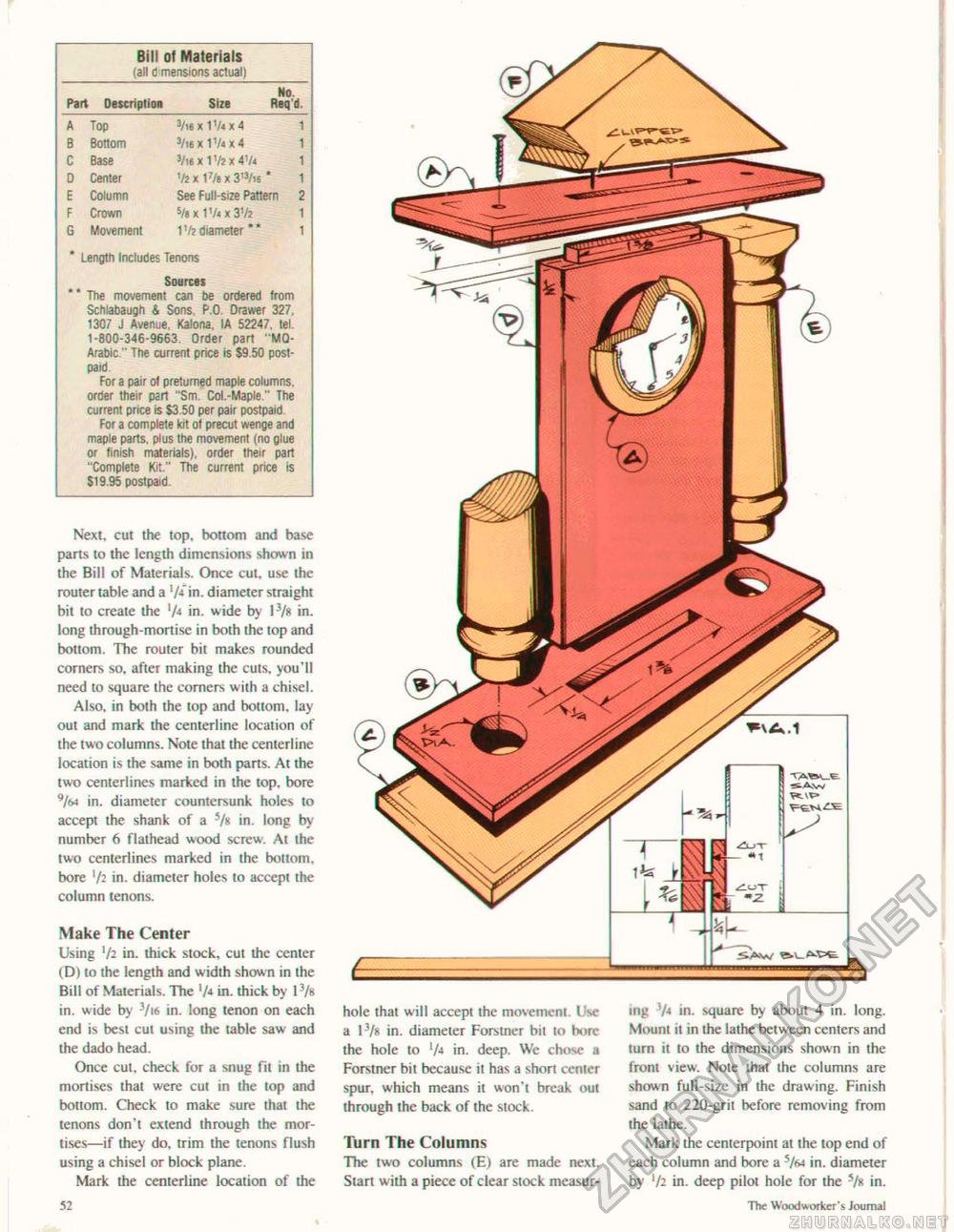

A Top B Bottom Base Center Column Crown Movement 3MX1'/4X4 1 3/ISX 1V4X4 1 3/l6XlVZX4V4 1 1/2 x 1 '/e X 3l3/is * 1 See Full-size Pattern 2 Vix1'/4x3Va 1 1 Vz diameter 1 Length Includes Tenons Sources ** The movement can be ordered from Schlabaugh & Sons. P.O. Drawer 327, 1307 J Avenue, Kaiona, IA 52247, tel. 1-800-346-9663. Order part "MO-Arabic." The current price is $9.50 postpaid For a pair of preturned maple columns, order their part "Sm. Col.-Maple" The current price is $3.50 per pair postpaid For a complete kit of precut wenge and maple parts, plus the movement (no glue or finish materials), order their part "Complete Kit." The current price is $19.95 postpaid. Next, cut the top, bottom and base parts to the length dimensions shown in the Bill of Materials. Once cut, use the router table and a 'A in. diameter straight bit to create the '/" in. wide by l3/s in-long through-mortise in both the top and bottom. The router bit makes rounded corners so, after making the cuts, you'll need to square the corners with a chisel. Also, in both ihe top and bottom, lay out and mark the centerline location of the two columns. Note that the centerline location is the same in both parts. At the two centerlines marked in the top, bore 9/m in. diameter countersunk holes to accept the shank of a s/» in. long by number 6 flathead wood screw. At the two centerlines marked in the bottom, bore '/2 in. diameter holes to accept the column tenons. Make The Center Using '/2 in. thick stock, cut the center (D) to the length and width shown in the Bill of Materials. The '/* in. thick by l3/8 in. wide by 3/i6 in. long tenon on each end is best cul using the table saw and the dado head. Once cut, check for a snug fit in the mortises that were cut in the lop and bottom. Check to make sure thai the tenons don't extend through the mortises—if they do, trim the tenons flush using a chisel or block plane. Mark the centerline location of the IX hole that will accept the movement. l:sc a 13/s in. diameter Forstner bit to bore the hole to 'A in. deep. We chose a Forstner bit because it has a short center spur, which means it won't break oui through the back of the stock. Turn The Columns The two columns (E) are made next. Start with a piece of clear stock measur ing 'A in. square by aboul 4 in. long. Mount it in the lathe between centers and turn it to the dimensions shown in the front view. Note that the columns are shown full-size in the drawing. Finish sand to 220-grit before removing from the lathe. Mark the centerpoint at the top end of each column and bore a in, diameter by '/2 in. deep pilol hole for the Vx in. The Woodworker'1, Journal |