Woodworker's Journal 1993-17-3, страница 25

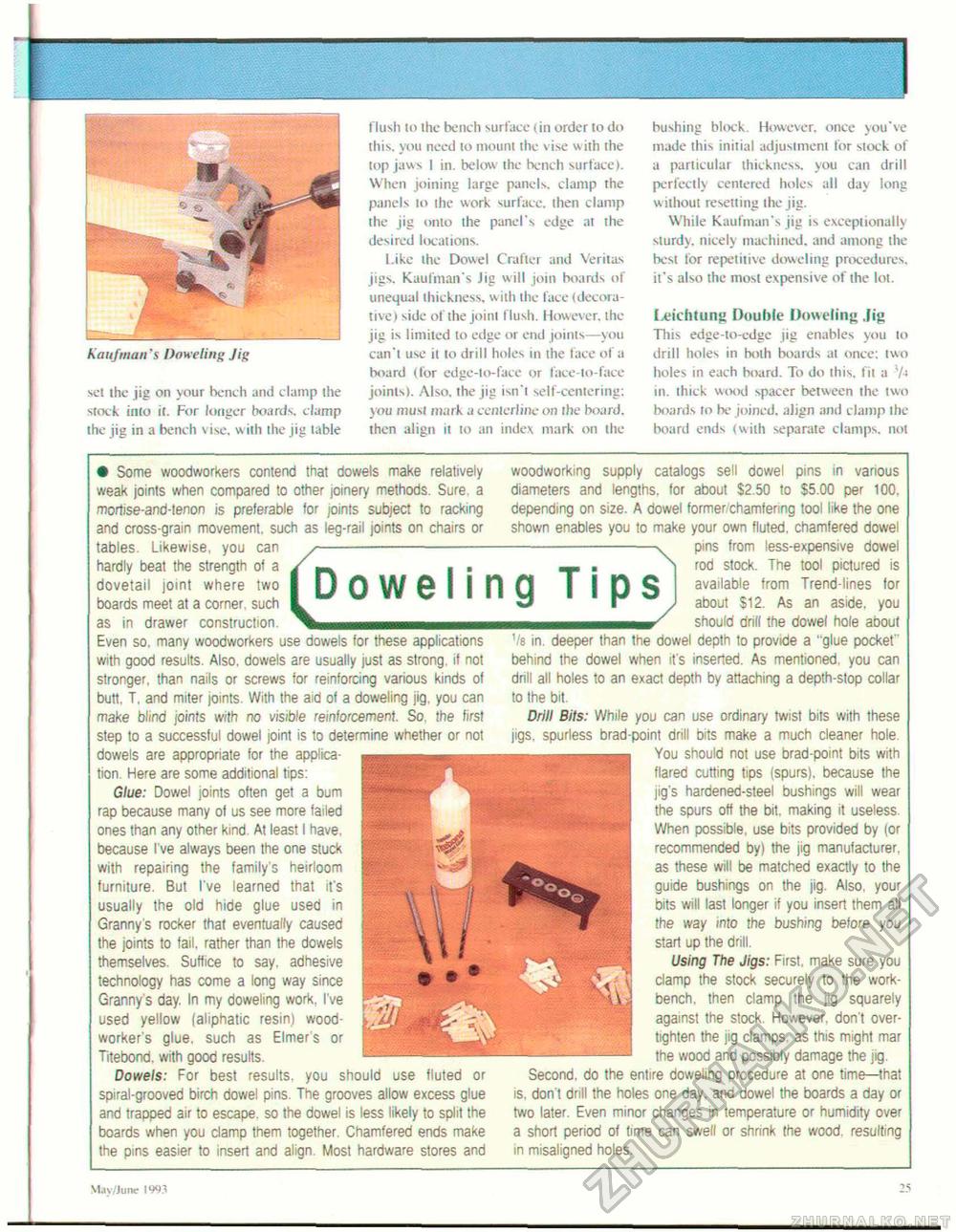

bushing block. However, once you've made this initial adjustment for stock of a particular thickness, you can drill perfectly centered holes all day long w ithout resetting the jig. While Kaufman's jig is exceptionally sturdy, nicely machined, and among the best lor repetitive doweling procedures, it's also the most expensive of the lot. fx-ichtung Double Doweling ,fig This edge-to-edge jig enables you to drill holes in both boards at once; tw'o holes in each board. To do this, fit a V-t in. thick wood spacer between the two boards to be joined, align and clamp the board ends (with separate clamps, not set the jig on your bench and clamp the stock into it. For longer boards, clamp the jig in a bench vise, with the jig table flush to the bench surface (in order to do this, you need to mount the vise w ith the top jaws I in. below the bcnch surface). When joining large panels, clamp the panels to the work surface, then clamp the jig onto the panel's edge at the desired locations. Like the Dowel Crafter and Veritas jigs, Kaufman's Jig will join boards (if unequal thickness, with the face (decorative* side of ihe joint flush. However, the jig is limited to edge or end joints—you can'l use it to drill holes in the face of a board (lor edge-to-face or face-lo-face jointsAlso, the jig isn't self-centering; you must mark a ccnleriine on ihe board, then align it to an index mark on the Doweling Tips • Some woodworkers contend that dowels make relatively weak joints when compared to other joinery methods. Sure, a mortise-and-tenon is preferable for joints subject to racking and cross-gram movement, such as leg-rail joints on chairs or tables. Likewise, you can hardly beat the strength of a dovetail joint where two boards meet at a corner, such as in drawer construction. Even so. many woodworkers use dowels for these applications with good results. Also, dowels are usually just as strong if not stronger, than nails or screws for reinforcing various kinds of butt. T. and miter joints. With the aid of a doweling jig, you can make blind joints with no visible reinforcement So. She first step to a successful dowel joint is to determine whether or not dowels are appropriate for the application. Here are some additional tips: Glue: Dowel joints often get a bum rap because many of us see more failed ones than any other kind. At least I have, because I've always been the one stuck with repairing the family's heirloom furniture. But I've learned that it's usually the old hide glue used in Granny's rocker that eventually caused the joints to fail, rather than the dowels themselves. Suffice to say. adhesive technology has come a long way since Granny's day. In my doweling work. I've used yellow (aliphatic resin) woodworker's glue, such as Elmers or Titebond. with good results. Dowe/s: For best results, you should use fluted or spiral-grooved birch dowel pins. The grooves allow excess glue and trapped air to escape, so the dowel is less likely to split the boards when you clamp them together. Chamfered ends make the pins easier to insert and align. Most hardware stores and woodworking supply catalogs sell dowel pins tn various diameters and lengths, for about S2.50 to $5.00 per 100, depending on size. A dowel former chamfering tool like the one shown enables you to make your own fluted, chamfered dowel -y pins from less-expensive dowel rod stock. The tool pictured is available from Trend-lines lor about $12. As an aside, you mmm—^^mmm^*/ should drill the dowel hole about Ve in. deeper than ihe dowel depth to provide a "glue pocket" behind Ihe dowel when it's inserted. As mentioned, you can drill all holes 1o an exact depth by attaching a depth-stop collar to the bit. Drill Bits: While you can use ordinary twist bits with these jigs, spurless brad-point drill bits make a much cleaner hole. You should not use brad-point bits with flared cutting tips (spurs), because the jig's hardened-steel bushings will wear the spurs off the bit. making it useless. When possible, use bits provided by (or recommended by) the jig manufacturer, as these will be matched exactly to the guide bushings on the jig, Also, your bits will last longer if you insert them all the way into the bushing before you start up the drill. Using The Jigs: First, make sure you clamp the stock securely to the workbench. then clamp the jig squarely against the stock, However, don't overtighten the jig clamps, as this might mar the wood and possibly damage the jig. Second, do the entire doweling procedure at one time—that is. don't drill the holes one day. and dowel the boards a day or two later. Even minor changes in temperature or humidity over a short period of time can swell or shrink the wood, resulting in misaligned holes May/June IV93 25 |