Woodworker's Journal 1993-17-3, страница 26

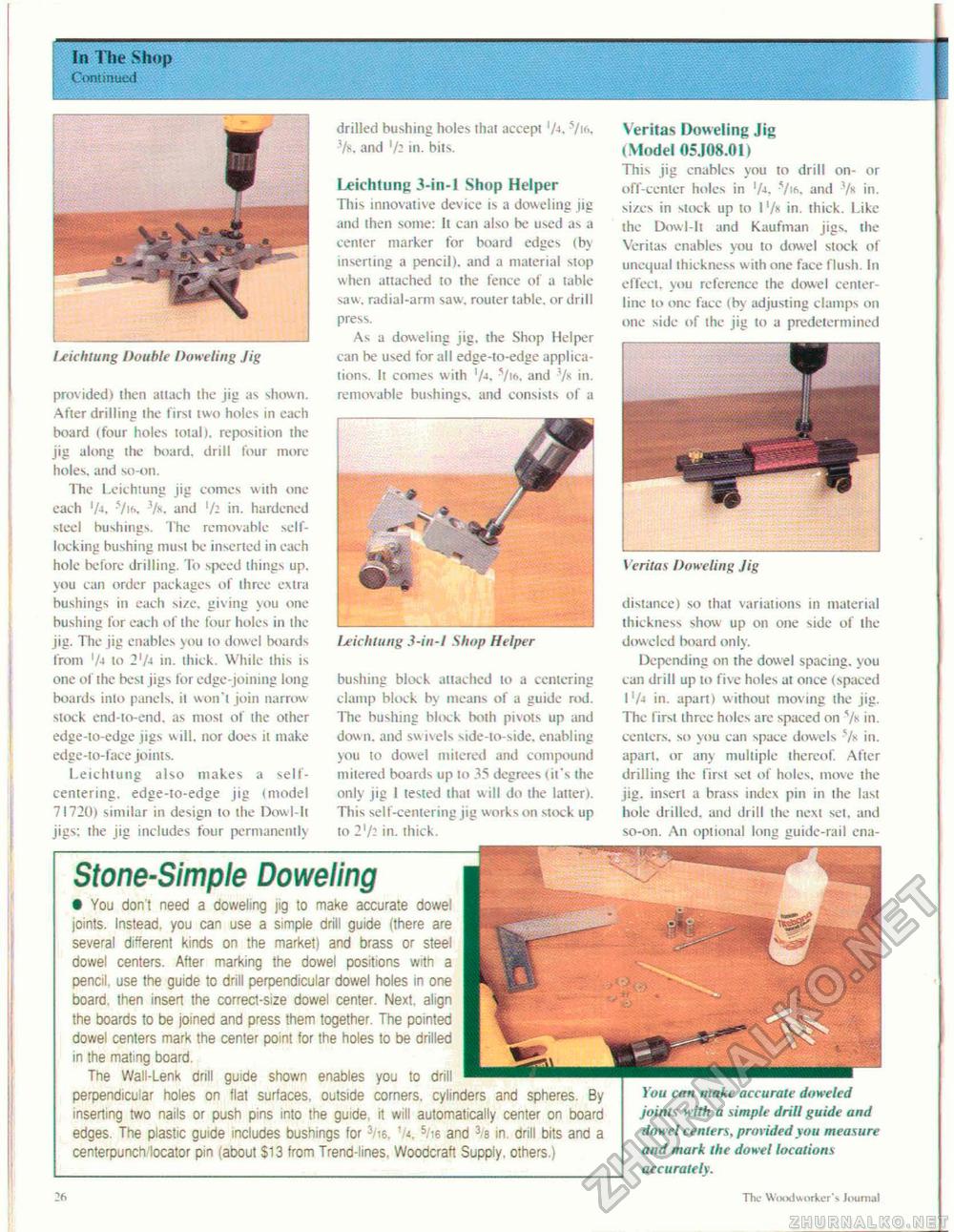

In The Shop Continued Ijeichtung Double Doweling Jig drilled bushing holes that accept Vir>. 7s. and in. bits. Leichtung 3-in-l Shop Helper This innovative device is a doweling jig and then some: It can also be used as a center marker for board edges (by inserting a pencil), and a material stop when attached to the fence of a table saw. radial-arm saw. router table, or drill press. As a doweling jig. the Shop Helper can be used for all edge-to-edge applications, li comes with '/■», 5/i6, and '/« in. removable bushings, and consists of a Veritas Doweling Jig (Model 05J08.01I This jig enables you to drill on- or off-center holes in 'A, V"»» and 7« in. si/.es in stock up to I in. thick. Like the Dowl-lt and Kaufman jigs, the Veritas enables you to dowel slock of unequal thickness with one face flush. In effect, you reference the dow:el cenler-line lo one face (by adjusting clamps on one side of the jig to a predetermined Veritas Doweling Jig provided) then altach the jig as shown. After drilling the first two holes in each board (four holes total), reposition (he jig along the board, drill four more holes, and so~on. The Leichtung jig comes with one each '/-i, s/lf>. -Vk, and lh in. hardened steel bushings. The removable self-locking bushing must be inserted in each hole before drilling. To speed things up. you can order packages of three extra bushings in each size, giv ing you one bushing for each of the four holes in ihe jig. The jig enables you to dowel boards from '/■» to 2'U in. thick. While this is one of ihe best jigs for edge-joining long boards into panels, il won'I join narrow stock end-to-end. as ntosi of the other edge-lo-edge jigs will, nor does it make edge-to-face joints. Leichtung also makes a self-centering, edge-to-edge jig (model 71720) similar in design to the Dowl-lt jigs: the jig includes four permanently distance) so that variations in material thickness show up on one side of Ihe doweled board only. Depending on the dowel spacing, you can drill up to five holes at once (spaced I'/4 in. apart) without moving the jig. The first three holes arc spaced on V* in. centers, so you can space dowels 7* in. apart, or any multiple thereof. After drilling ihe first set of holes, move the jig, inserl a brass index pin in the last hole drilled, and drill the next set. and so-on. An optional long guide-rail ena- Stone-Simple Doweling • You don't need a doweling jig to make accurate dowel joints, instead, you can use a simple drill guide (there are several different kinds on the market) and brass or steei dowel centers. After marking the dowel positions with a pencil, use the guide to drill perpendicular dowel holes in one board, then insert the correct-size dowel center. Next, align the boards to be joined and press them together. The pointed dowel centers mark the center point for the holes lo be drilled in the mating board. The Wali-Lenk drill guide shown enables you to drill perpendicular holes on flat surfaces, outside corners, cylinders and spheres. By inserting two nails or push pins into the guide, it will automatically center on board edges. The plastic guide includes bushings lor 3;16, ' t, 5. ie and 3.b in. drill bits and a centerpunch locator pin (about $13 from Trend-lines, Woodcrafl Supply, others.) You can make accurate doweled joints with a simple drill guide and dowel centers, provided you measure and mark the dowel locations accurately. Ijeichtung 3-in-l Shop Helper bushing block attached to a centering clamp block by means of a guide rod. The bustling block both pivots up and down, and sw ivels side-to-side. enabling you lo dowel inhered and compound mitered boards up to 35 degrees (it's the only jig I tested that w ilt do the latter). This self-centering jig works on stock up to 2V: in. thick. 26 ~t"he Woodworker's Journal |