Woodworker's Journal 2008-32-2, страница 50

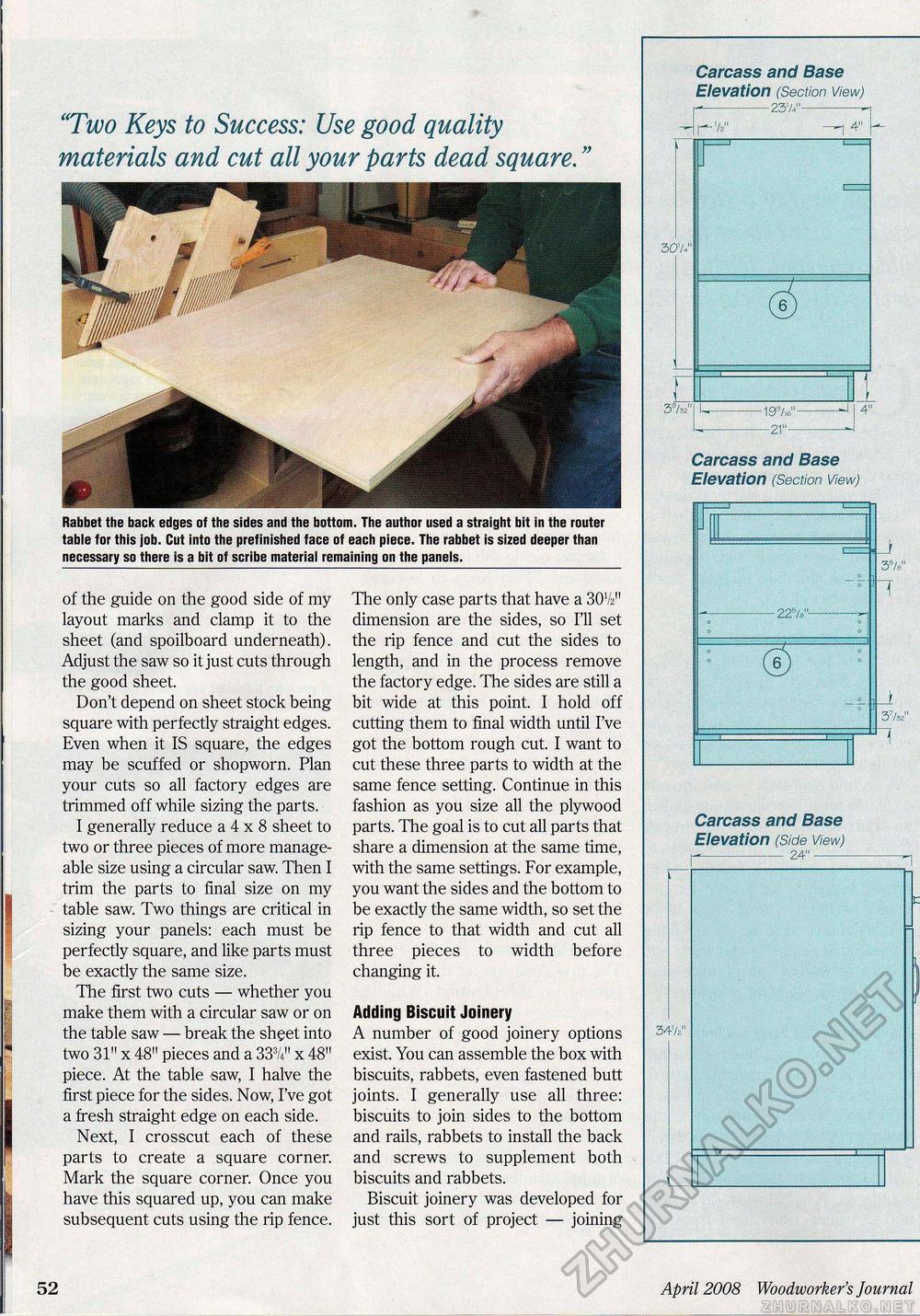

of the guide on the good side of my layout marks and clamp it to the sheet (and spoilboard underneath). Adjust the saw so it just cuts through the good sheet. Don't depend on sheet stock being square with perfectly straight edges. Even when it IS square, the edges may be scuffed or shopworn. Plan your cuts so all factory edges are trimmed off while sizing the parts. I generally reduce a 4 x 8 sheet to two or three pieces of more manageable size using a circular saw. Then I trim the parts to final size on my table saw. Two things are critical in sizing your panels: each must be perfectly square, and like parts must be exactly the same size. The first two cuts — whether you make them with a circular saw or on the table saw — break the sheet into two 31" x 48" pieces and a 33%" x 48" piece. At the table saw, I halve the first piece for the sides. Now, I've got a fresh straight edge on each side. Next, I crosscut each of these parts to create a square corner. Mark the square corner. Once you have this squared up, you can make subsequent cuts using the rip fence. The only case parts that have a 30: dimension are the sides, so I'll set the rip fence and cut the sides to length, and in the process remove the factory edge. The sides are still a bit wide at this point. I hold off cutting them to final width until I've got the bottom rough cut. I want to cut these three parts to width at the same fence setting. Continue in this fashion as you size all the plywood parts. The goal is to cut all parts that share a dimension at the same time, with the same settings. For example, you want the sides and the bottom to be exactly the same width, so set the rip fence to that width and cut all three pieces to width before changing it. Adding Biscuit Joinery A number of good joinery options exist. You can assemble the box with biscuits, rabbets, even fastened butt joints. I generally use all three: biscuits to join sides to the bottom and rails, rabbets to install the back and screws to supplement both biscuits and rabbets. Biscuit joinery was developed for just this sort of project — joining Carcass and Base Elevation (Section View) 23V," --------- 3O'U 34/;," Rabbet the back edges of the sides and the bottom. The author used a straight bit in the router table for this job. Cut into the prefinished face of each piece. The rabbet is sized deeper than necessary so there is a bit of scribe material remaining on the panels. Carcass and Base Elevation (Section View) Carcass and Base Elevation (Side View) "Two Keys to Success: Use good quality materials and cut all your parts dead square." 52 April 2008 Woodworker's Journal |