Woodworker's Journal 2010-34-2, страница 37

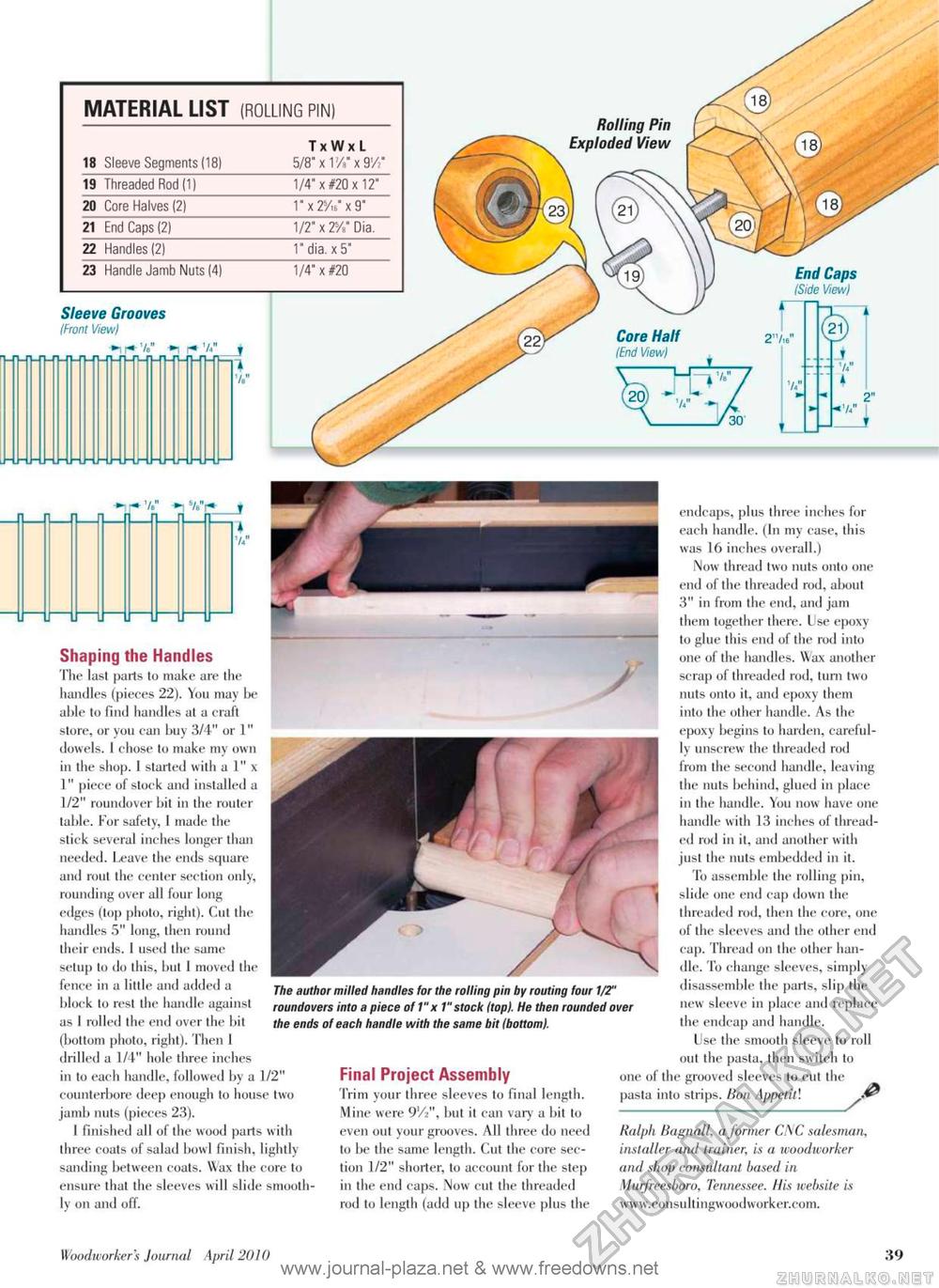

Rolling Pin Exploded View End Caps (Side View) Sleeve Grooves IFront View) r* 7b" »i r* 'A" Core Half (End View) ■*'/«" 15A>nr» k V Shaping the Handles The lasl parts lo make are the handles (pieces 22). You may be able to find handles at a craft store, or you can buy 3/4" or 1" dowels. 1 chose to make my own in the shop. I started with a 1" x 1" piece of stock and installed a 1/2" roundover bit in the router table. For safety, 1 made the stick several inches longer than needed. Leave the ends square and rout the center section only, rounding over all four long edges (top photo, right). Cut the handles 5" long, then round their ends. 1 used the same setup to do this, but 1 moved the fence in a little and added a block to rest the handle against as 1 rolled the end over the bit (bottom photo, right). Then 1 drilled a 1/4" hole three inches in lo each handle, followed by a 1/2" counterbore deep enough to house two jamb nuts (pieces 23). I finished all of the wood parts with three coats of salad bowl finish, lightly sanding between coats. Wax the core to ensure that the sleeves will slide smoothly on and off. The author milled handles for the rolling pin by routing four 1/2" roundovers into a piece of 1"x 1" stock (top). He then rounded over the ends of each handle with the same bit (bottom). Final Project Assembly Trim your three sleeves to final length. Mine were 9'A", but it can vary a bit to even out your grooves. All three do need to be the same length. Cut the core section 1/2" shorter, to account for the step in the end caps. .Now cut the threaded rod to length (add up the sleeve plus the endcaps, plus three inches for each handle. (In my case, this was 16 inches overall.) Now thread two nuts onto one end of the threaded rod, about 3" in from the end, and jam them together there. Use epoxy to glue this end of the rod into one of the handles. Wax another scrap of threaded rod, turn two nuts onto it, and epoxy them into the other handle. As the epoxy begins to harden, carefully unscrew the threaded rod from the second handle, leaving the nuts behind, glued in place in the handle. You now have one handle with 13 inches of threaded rod in it, and another w ith just the nuts embedded in it. To assemble the rolling pin, slide one end cap down the threaded rod, then the core, one of the sleeves and the other end cap. Thread on the other handle. To change sleeves, simply disassemble the parts, slip the new sleeve in place and replace the endcap and handle. llse the smooth sleeve to roll out the pasta, then switch to one of the grooved sleeves to cut the pasta into strips. Bon Appetit! y Ralph Bagnall, a former CSC salesman, installer and trainer, is a woodworker and shop consultant based in Miufreesboro, Tennessee. His website is www.consultingwoodworker.com. Woodworker's Journal April 2010 www.journal-plaza.net & www.freedowns.net it |

||||||||||||||