Woodworker's Journal 2010-34-2, страница 38

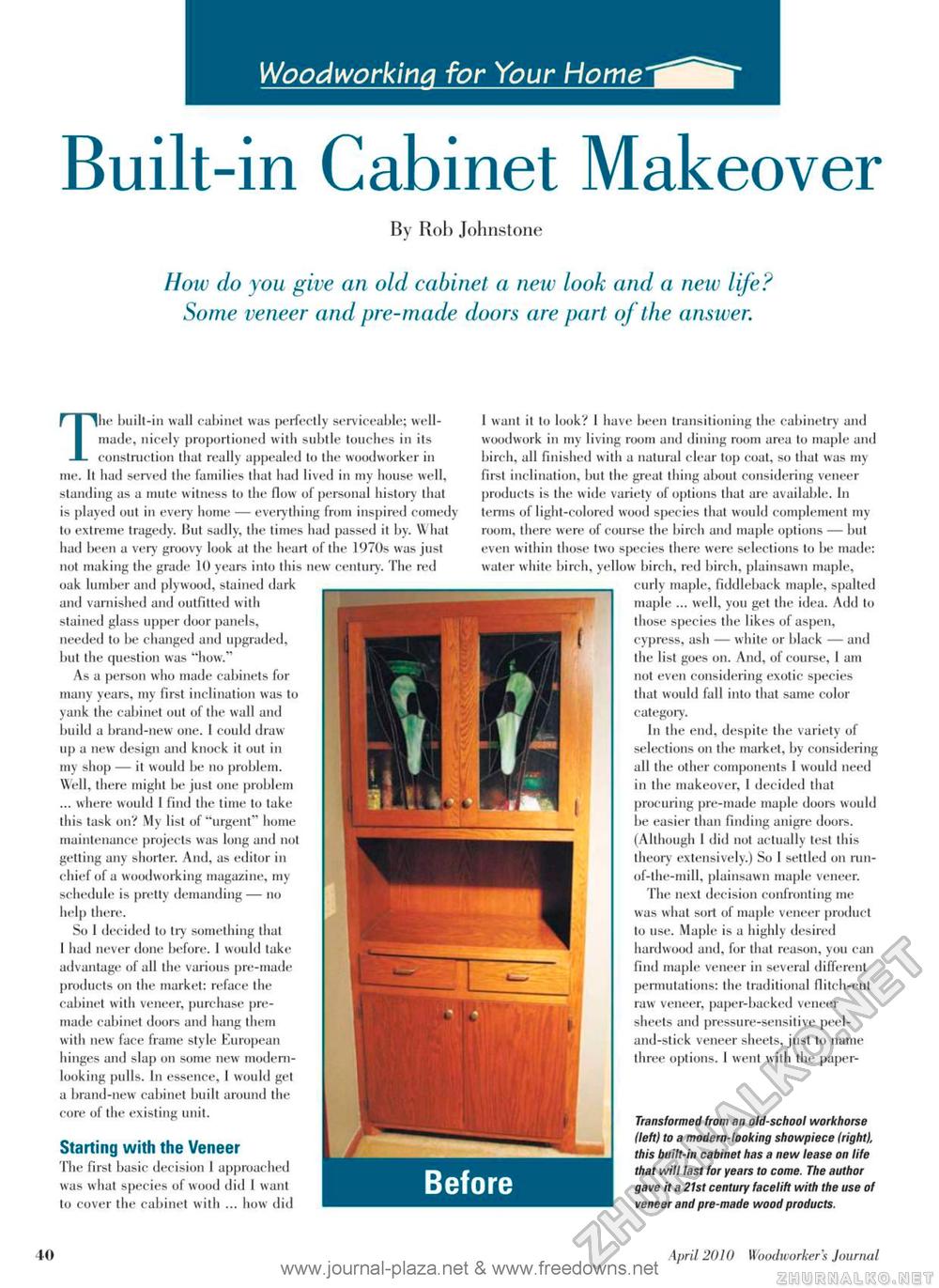

Woodworking for Your Home' Built-in Cabinet MakeoverBy Roll Johnstone How do you give an old cabinet a new look and a new life? Some veneer and pre-made doors are part of the ans wer. The built-in wall cabinet was perfectly serviceable; well-made, nicely proportioned with subtle touches in its construction that really appealed to the woodworker in me. It had served the families that had lived in my house well, standing as a mute witness to the flow of personal history that is played out in every home — everything from inspired comedy to extreme tragedy. But sadly, the times had passed it by. What had been a very groovy look at the heart of the 1970s was just not making the grade 10 years into this new century. The red oak lumber and plywood, stained dark and varnished and outfitted with stained glass upper door panels, needed to be changed and upgraded, but the question was "how." As a person who made cabinets for many years, my first inclination was to yank the cabinet out of the wall and build a brand-new one. 1 could draw up a new design and knock it out in my shop — it would be no problem. Well, there might be just one problem ... where would 1 find the time to take this task on? My list of "urgent" home maintenance projects was long and not getting any shorter. And, as editor in chief of a woodworking magazine, my schedule is pretty demanding — no help there. So 1 decided lo try something that I had never done before. 1 would take advantage of all llie various pre-made products on the market: reface the cabinet with veneer, purchase pre-made cabinet doors and hang them with new face frame style European hinges ami slap on some new modern-looking pulls. In essence, I would get a brand-new cabinet built around the core of the existing unit. Starting with the Veneer The first basic decision 1 approached was what species of wood did 1 want lo cover the cabinet with ... how did 1 want it to look? 1 have been transitioning the cabinetry and woodwork in my living room and dining room area to maple and birch, all finished with a natural clear top coat, so that was my first inclination, but the great thing about considering veneer products is the wide variety of options that are available. In terms of light-colored wood species that would complement my room, there were of course the birch and maple options — but even within those two species there were selections to be made: water white birch, yellow birch, red birch, plainsawn maple, curly maple, fiddleback maple, spalted maple ... well, you gel the idea. Add lo those species the likes of aspen, cypress, ash — white or black — and the list goes on. And, of course, 1 am not even considering exotic species that would fall into that same color category. In the end, despite the variety of selections on the market, by considering all the other components 1 would need in the makeover, 1 decided that procuring pre-made maple doors would be easier than finding anigre doors. (Although I did not actually test this theory extensively.) So 1 settled on run-of-the-mill, plainsawn maple veneer. The next decision confronting me was what sort of maple veneer product to use. Maple is a highly desired hardwood and, for thai reason, you can find maple veneer in several different permutations: the traditional flitch-cut raw veneer, paper-backed veneer sheets and pressure-sensitive peel-and-stick veneer sheets, just lo name three options. I went with the paper- Transformed from an old-school workhorse (left} to a modern-looking showpiece (right), this built-in cabinet has a new lease on life that will last for years to come. The author gave it a 21st century facelift with the use of veneer and pre-made wood products. 40 April 2010 Woodworkers Jourruil |