Woodworker's Journal 2010-34-2, страница 35

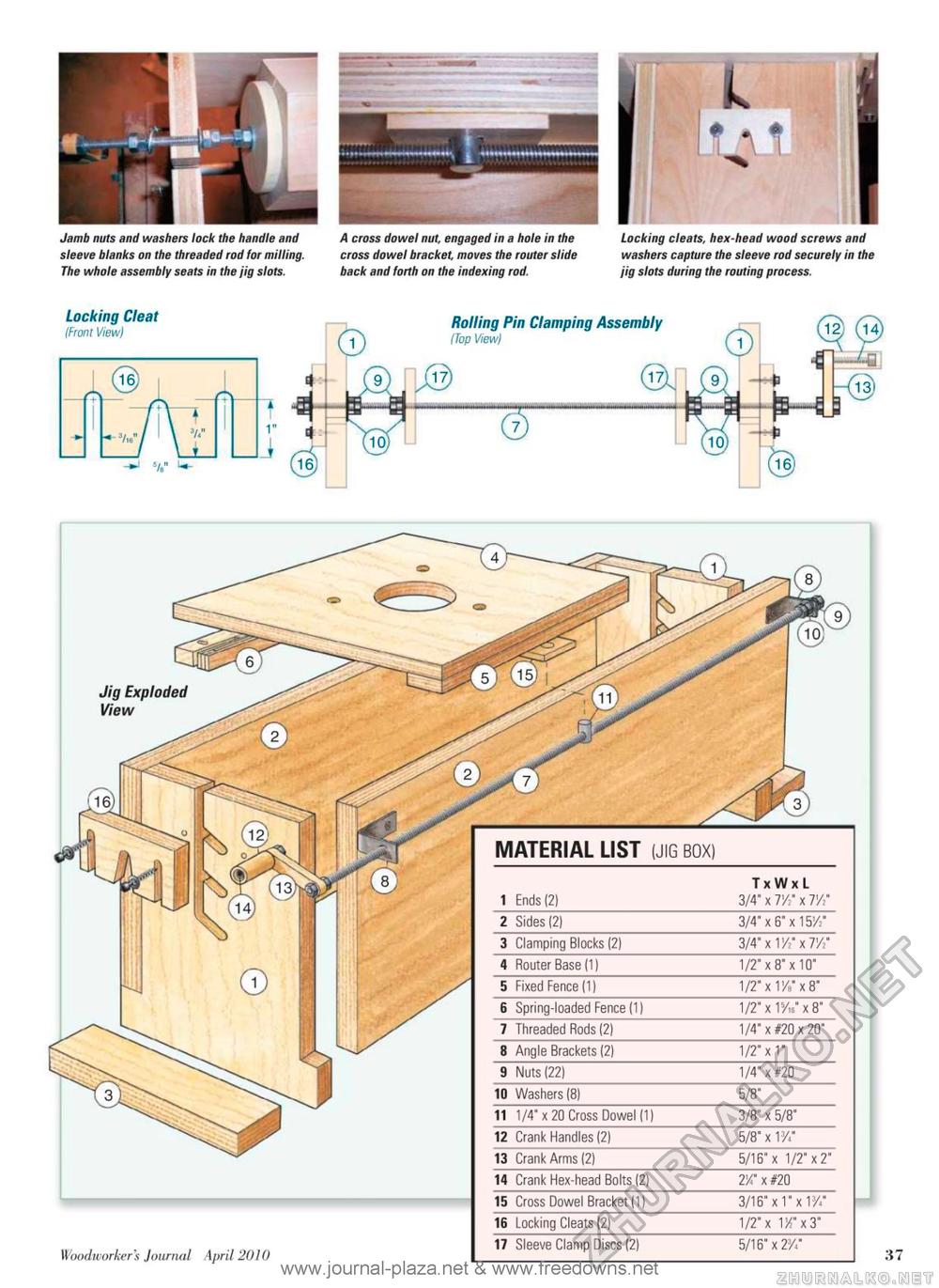

kr k I lAl Jamb nuts and washers lock the handle and sleeve blanks on the threaded rod for milling. The whole assembly seats in the jig slots. A cross dowel nut, engaged in a hole in the cross dowel bracket, moves the router slide back and forth on the indexing rod. Locking cleats, hex-head wood screws and washers capture the sleeve rod securely in the jig slots during the routing process. Locking Cleat IFront View) it Woodworker's Journal April 2010 17 Sleeve Clamp Discs (2) 5/16" x 2'/' www.journal-plaza.net & www.freedowns.net MATERIAL LIST (JIG BOX) 1 Ends(2) TxWxL 3/4" x TA' x IV" 2 Sides (2) 3/4" x 6" x 15/2" 3 Clamping Blocks (2) 3/4" x V/i x TA' 4 Router Base(1) 1/2" x 8" x 10" 5 Fixed Fence (1) 1/2" x 1'/8" x 8" 6 Spring-loaded Fenced) 1/2" x 15A" x 8" 7 Threaded Rods (2) 1/4" x #20x20" 8 Angle Brackets (2) 1/2" x1" 9 Nuts (22) 1/4"x #20 10 Washers (8) 5/8" 11 1/4" x 20 Cross Dowel (1) 3/8" x 5/8" 12 Crank Handles (2) 5/8" x13// 13 Crank Arms (2) 5/16" x 1/2" x 2" 14 Crank Hex-head Bolts (2) TA" x #20 15 Cross Dowel Bracket (1) 3/16" x 1" x VA" 16 Locking Cleats (2) 1/2" x 1K"x3" Jig Exploded View |