Woodworker's Journal 2010-34-2, страница 33

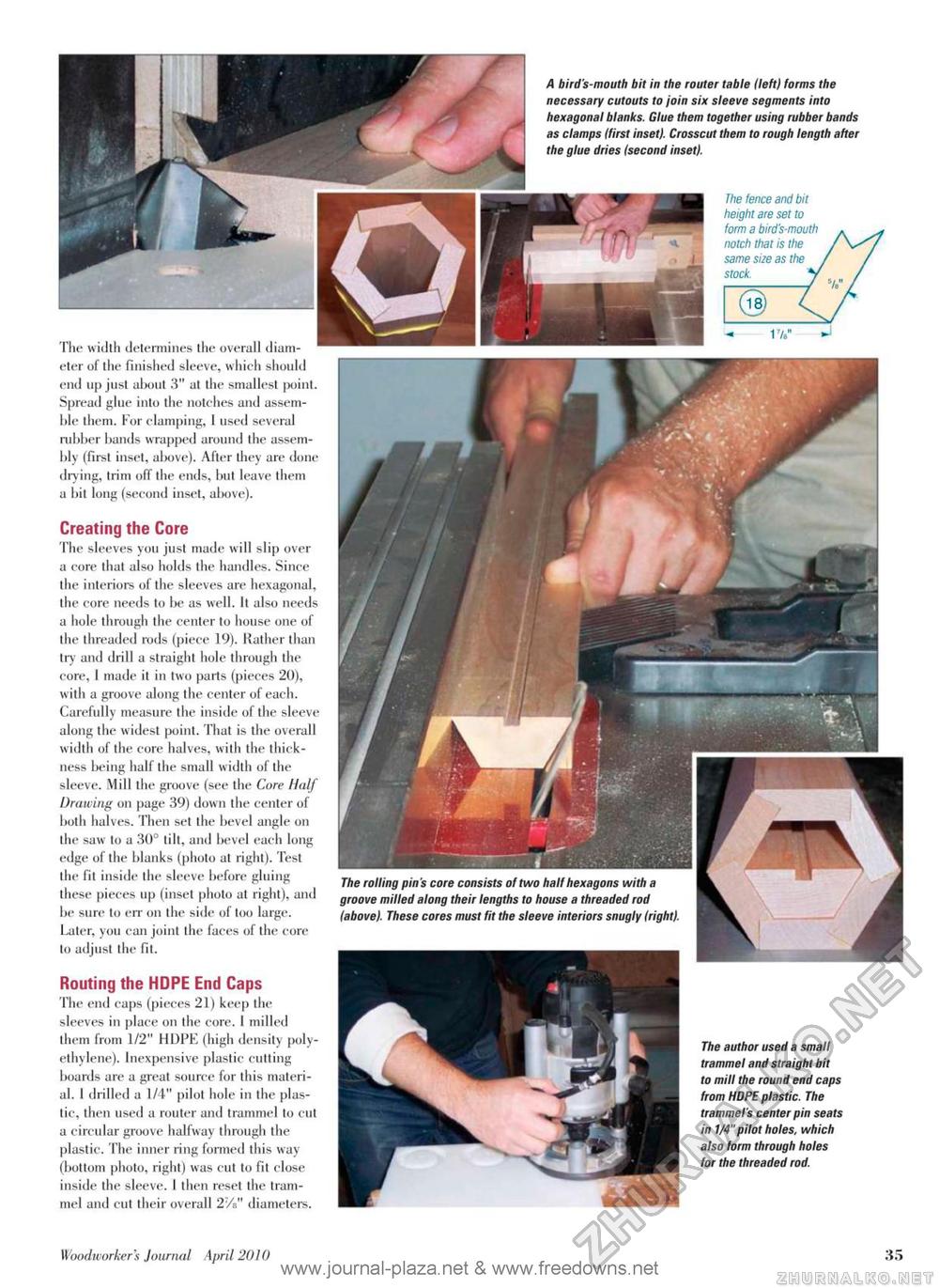

The rolling pin's core consists of two half hexagons with a groove milled along their lengths to house a threaded rod (above). These cores must fit the sleeve interiors snugly (right). The author used a small trammel and straight bit to mill the round end caps from HDPE plastic. The trammel's center pin seats in 1/4" pilot holes, which also form through holes for the threaded rod. The width determines the overall diameter of the finished sleeve, which should end up just about 3" at the smallest [M)int, Spread glue into the notches and assemble them. For clamping, 1 used several rubber bands wrapped around the assembly (first inset, above). After they are done drying, trim of! the ends, but leave them a bit long (second inset, above). A bird's-mouth bit in the router table (left) forms the necessary cutouts to join six sleeve segments into hexagonal blanks. Clue them together using rubber bands as clamps (first inset). Crosscut them to rough length after the glue dries (second inset). The fence and bit height are set to form a bird's-mouth notch that is the same size as the stock. Creating the Core The sleeves you just made will slip over a core that also holds the handles. Since the interiors of the sleeves are hexagonal, the core needs to be as well. It also needs a hole through the center to house one of the threaded rods (piece 19). Rather than try and drill a straight hole through the core, I made it in two parts (pieces 20), with a groove along the center of each. Carefully measure the inside of the sleeve along the widest point. That is the overall width of the core halves, with the thickness being half the small width of the sleeve. Mill the groove (see the Core Half Drawing on page 39) down the center of both halves. Then set the bevel angle on the saw to a 30° till, and bevel each long edge of the blanks (photo at right). Test the fit inside the sleeve before gluing these pieces up (inset photo at right), and be sure to err on the side of too large. Later, you can joint the faces of the core lo adjust the fit. Routing the HDPE End Caps The end caps (pieces 21) keep the sleeves in place on the core. I milled them from 1/2" HDPE (high density polyethylene). Inexpensive plastic cutting boards are a great source for this material. I drilled a 1/4" pilot hole in the plastic, then used a router and trammel lo cut a circular groove halfway through the plastic. The inner ring formed this way (bottom photo, right) was cut to fit close inside the sleeve. I then reset the trammel and cut their overall 2r/a" diameters. Woodworker's Journal April 2010 it |