Woodworker's Journal fall-2010, страница 23

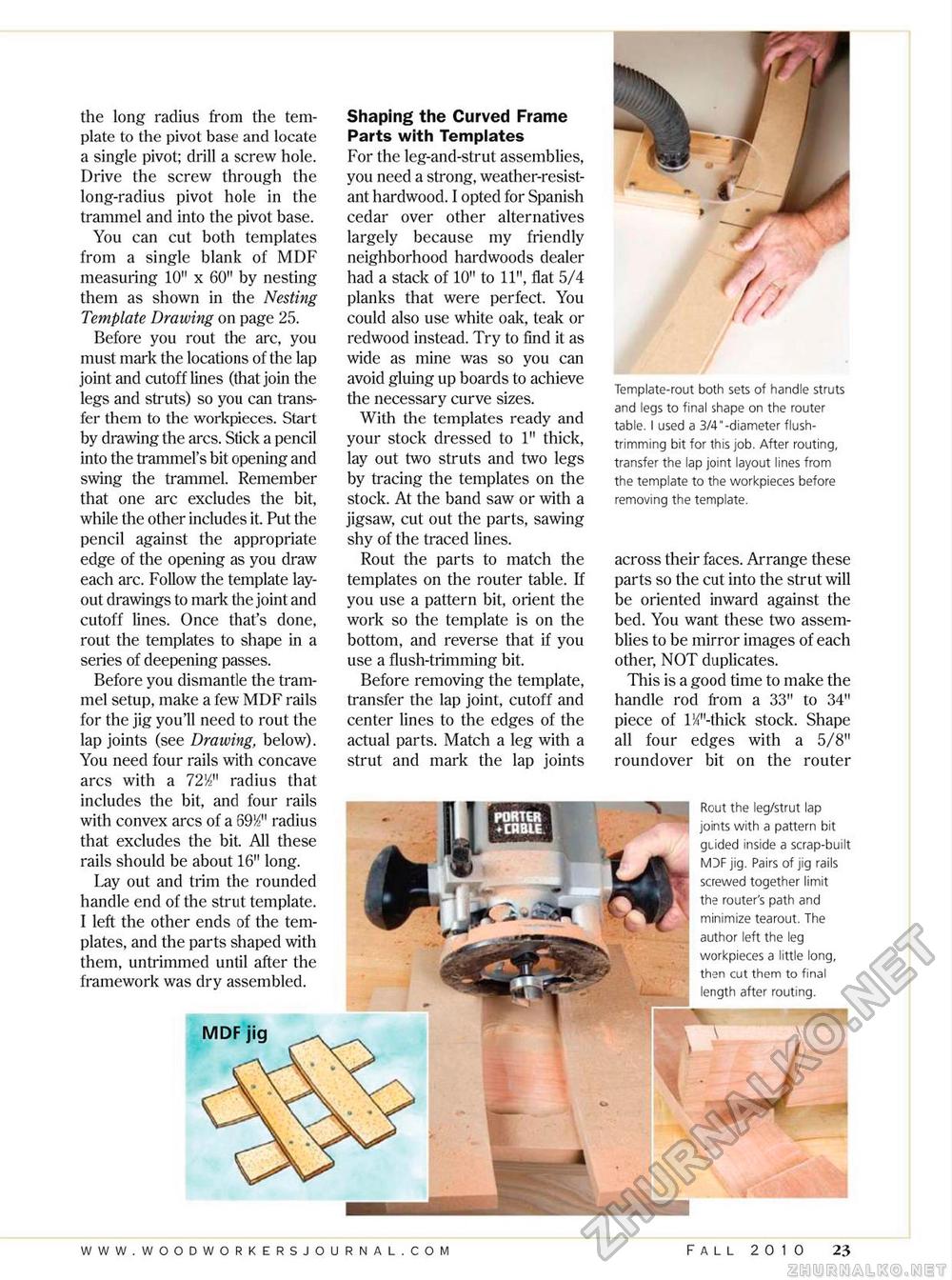

the long radius from the template to the pivot base and locate a single pivot; drill a screw hole. Drive the screw through the long-radius pivot hole in the trammel and into the pivot base. You can cut both templates from a single blank of MDF measuring 10" x 60" by nesting them as shown in the Nesting Template Drawing on page 25. Before you rout the arc, you must mark the locations of the lap joint and cutoff lines (that join the legs and struts) so you can transfer them to the workpieces. Start by drawing the arcs. Stick a pencil into the trammel's bit opening and swing the trammel. Remember that one arc excludes the bit, while the other includes it. Put the pencil against the appropriate edge of the opening as you draw each arc. Follow the template layout drawings to mark the joint and cutoff lines. Once that's clone, rout the templates to shape in a series of deepening passes. Before you dismantle the trammel setup, make a few MDF rails for the jig you'll need to rout the lap joints (see Drawing, below). You need four rails with concave arcs with a 72,/>" radius that includes the bit, and four rails with convex arcs of a 69/4" radius that excludes the bit. All these rails should be about 16" long. Lay out and trim the rounded handle end of the strut template. I left the other ends of the templates, and the parts shaped with them, untrimmed until after the framework was dry assembled. MDF jig Shaping the Curved Frame Parts with Templates For the leg-and-strut assemblies, you need a strong, weather-resistant hardwrood. I opted for Spanish cedar over other alternatives largely because my friendly neighborhood hardwoods dealer had a stack of 10" to 11", flat 5/4 planks that were perfect. You could also use white oak, teak or redwood instead. Try to find it as wide as mine was so you can avoid gluing up boards to achieve the necessary curve sizes. With the templates ready and your stock dressed to 1" thick, lay out two struts and two legs by tracing the templates on the stock. At the band saw or with a jigsaw, cut out the parts, sawing shy of the traced lines. Rout the parts to match the templates on the router table. If you use a pattern bit, orient the work so the template is on the bottom, and reverse that if you use a flush-trimming bit. Before removing the template, transfer the lap joint, cutoff and center lines to the edges of the actual parts. Match a leg with a strut and mark the lap joints PORTER ♦CHBIE / / / t Temp late-rout both sets of handle struts and legs to final shape on the router table. I used a 3/4"-diameter flush-trimming bit for this job. After routing, transfer the lap joint layout lines from the template to the workpieces before removing the template. across their faces. Arrange these parts so the cut into the strut will be oriented inward against the bed. You want these two assemblies to be mirror images of each other, NOT duplicates. This is a good time to make the handle rod from a 33" to 34" piece of lM"-thick stock. Shape all four edges with a 5/8" roundover bit on the router Rout the leg/strut lap joints with a pattern bit glided inside a scrap-built MDF jig. Pairs of jig rails screwed together limit the router's path and minimize tearout. The author left the leg workpieces a little long, then cut them to final length after routing. i

Fall 2010 23 |

|||||