15 - Sliding Table, страница 18

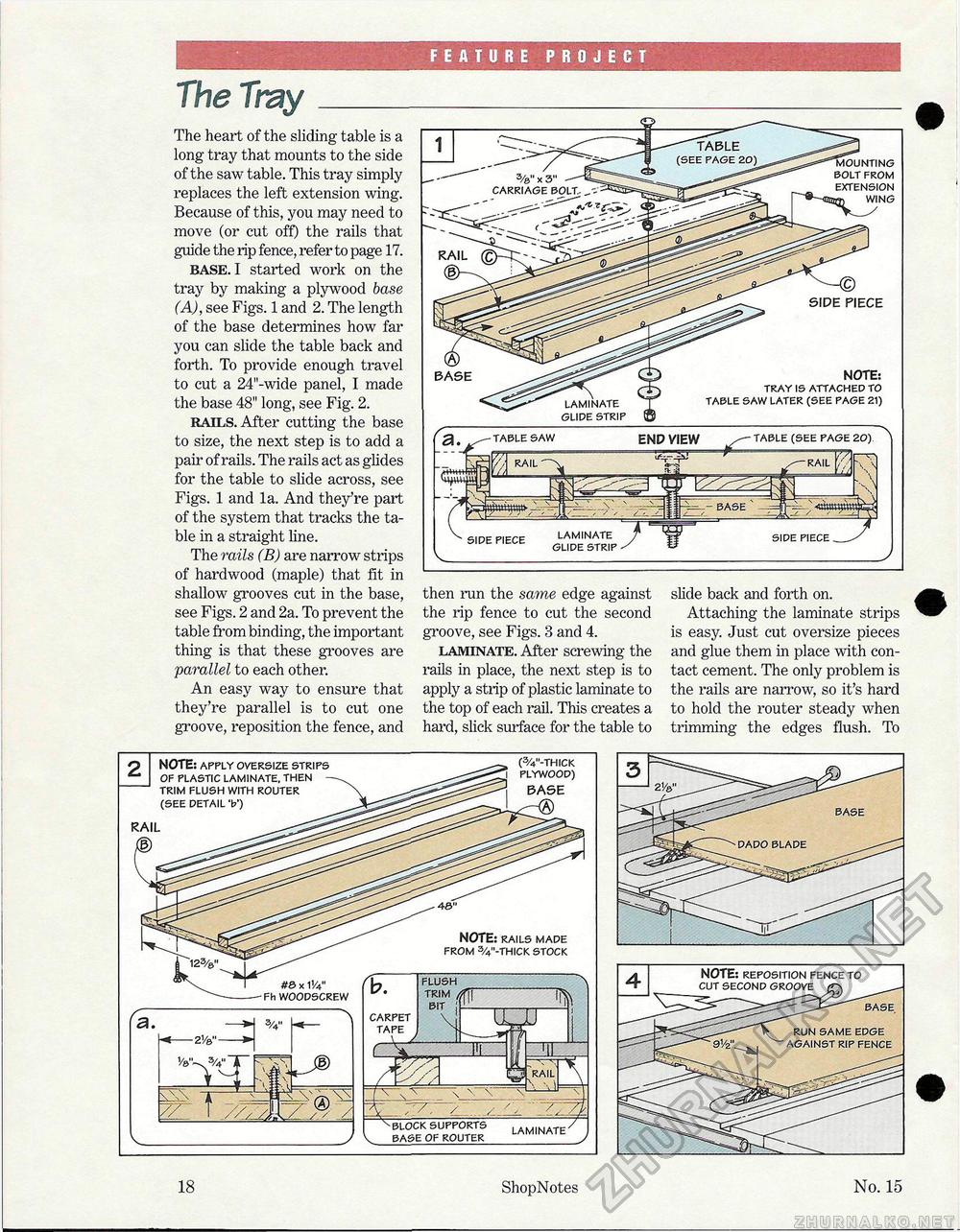

FEATURE PROJECT The Tray_ The heart of the sliding table is a long tray that mounts to the side of the saw table. This tray simply replaces the left extension wing. Because of this, you may need to move (or cut off) the rails that guide the rip fence, refer to page 17. base. I started work on the tray by making a plywood base (A), see Figs. 1 and 2. The length of the base determines how far you can slide the table back and forth. To provide enough travel to cut a 24"-wide panel, I made the base 48" long, see Fig. 2. rails. After cutting the base to size, the next step is to add a pair of rails. The rails act as glides for the table to slide across, see Figs. 1 and la. And they're part of the system that tracks the table in a straight line. The rails (B) are narrow strips of hardwood (maple) that fit in shallow grooves cut in the base, see Figs. 2 and 2a. To prevent the table from binding, the important thing is that these grooves are parallel to each other. An easy way to ensure that they're parallel is to cut one groove, reposition the fence, and then run the same edge against the rip fence to cut the second groove, see Figs. 3 and 4. laminate. After screwing the rails in place, the next step is to apply a strip of plastic laminate to the top of each rail. This creates a hard, slick surface for the table to slide back and forth on. Attaching the laminate strips is easy. Just cut oversize pieces and glue them in place with contact cement. The only problem is the rails are narrow, so it's hard to hold the router steady when trimming the edges flush. To RAIL SIDE PIECE BASE GLIDE STRIP NOTE: TRAY IS ATTACHED TO TABLE SAW LATER (SEE PAGE 21) TABLE (SEE PAGE 20) BOLT FROM %" x 3" carriage bolt- RAIL 2 NOTE: RAILS MADE FROM 3/4"-THICK STOCK NOTE: APPLY OVERSIZE STRIPS OF PLASTIC LAMINATE, THEN TRIM FLUSH WITH ROUTER (SEE DETAIL v) (3/4"-THICK PLYWOOD) BASE CARPET TAPE FLUSH TRIM BIT #& x 11/4" Fh WOODSCREW 18 ShopNotes No. 15 |