25 - Special Table Saw Issue, страница 10

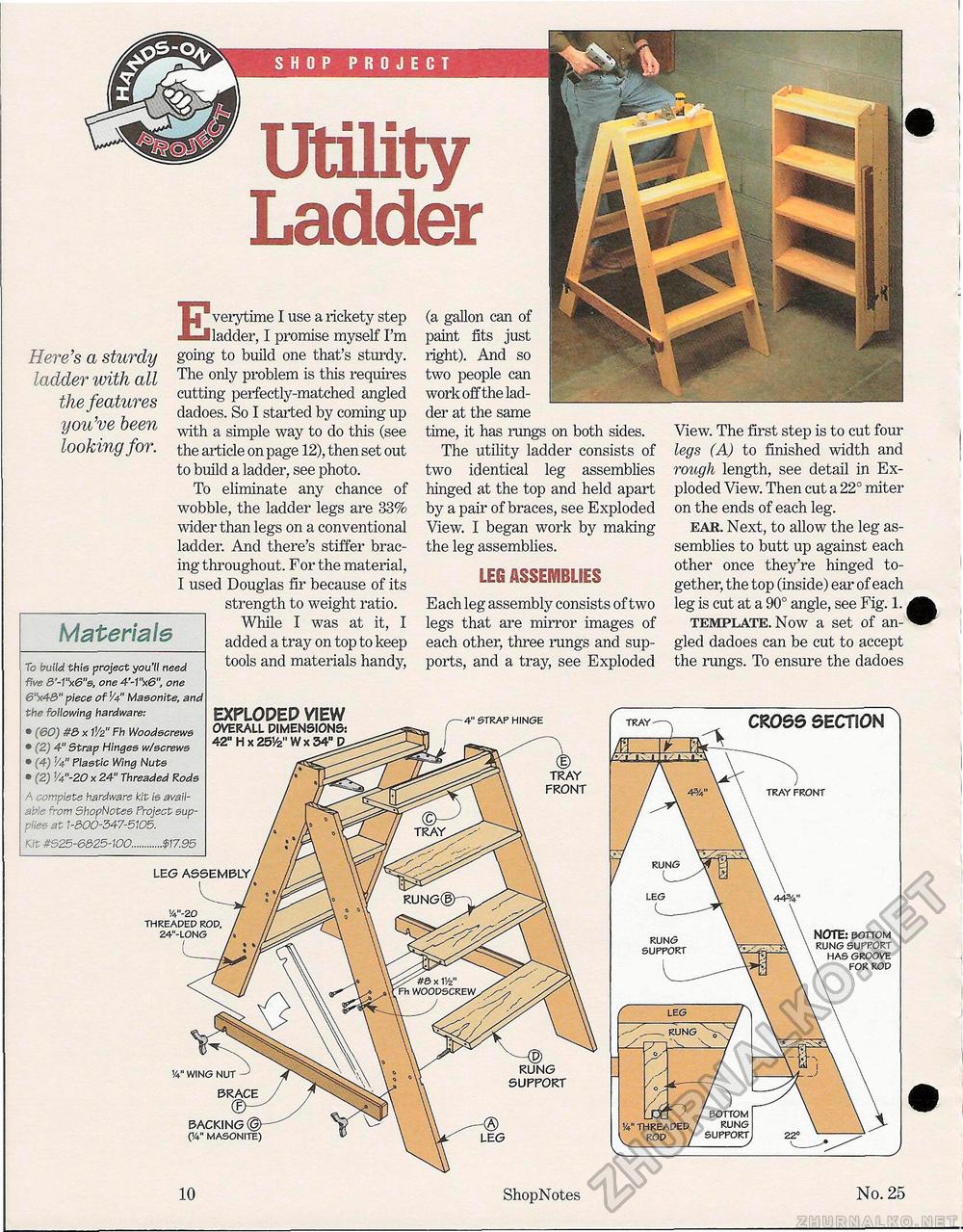

Here's a sturdy ladder with all the features you've been looking for. Materials To build this project you'll need five 3'-1"x6"s, one 4'-V'x6", one 6"x43" piece of 1A" Masonite, and the following hardware: • (60) #& x 1 Yz" Fh Woodscrews • (2) 4" Strap Hinges w/screws • (4) h" Plastic Wing Nuts • (2) V4"-20 x 24" Threaded Rods A complete hardware kit is available from ShopNotes Project supplies at 1-300-347-5105. Kit #S25-6&25-100............$17.95 Everytime I use a rickety step ladder, I promise myself I'm going to build one that's sturdy. The only problem is this requires cutting perfectly-matched angled dadoes. So I started by coming up with a simple way to do this (see the article on page 12), then set out to build a ladder, see photo. To eliminate any chance of wobble, the ladder legs are 33% wider than legs on a conventional ladder. And there's stiffer bracing throughout. For the material, I used Douglas fir because of its _ strength to weight ratio. While I was at it, I added a tray on top to keep tools and materials handy, EXPLODED VIEW OVERALL DIMENSIONS: 42" H x 251/2" W x 34" rung Utility Ladder leg W'-zo threaded rod, 24"-l0ng 14" threaded 4" strap hinge tray front (a. gallon can of paint fits just right). And so two people can work off the lad der at the same time, it has rungs on both sides. The utility ladder consists of two identical leg assemblies hinged at the top and held apart by a pair of braces, see Exploded View. I began work by making the leg assemblies. LEG ASSEMBLIES Each leg assembly consists of two legs that are mirror images of each other, three rungs and supports, and a tray, see Exploded View. The first step is to cut four legs (A) to finished width and rough length, see detail in Exploded View. Then cut a 22° miter on the ends of each leg. ear. Next, to allow the leg assemblies to butt up against each other once they're hinged together, the top (inside) ear of each leg is cut at a 90° angle, see Fig. 1. template. Now a set of angled dadoes can be cut to accept the rungs. To ensure the dadoes 1/4" wing nut backing OA- support CROSS SECTION^ NOTE: bottom rung support has groove for rop tray front rung support 10 ShopNotes No. 25 |