36 - Miter Trimmer, страница 8

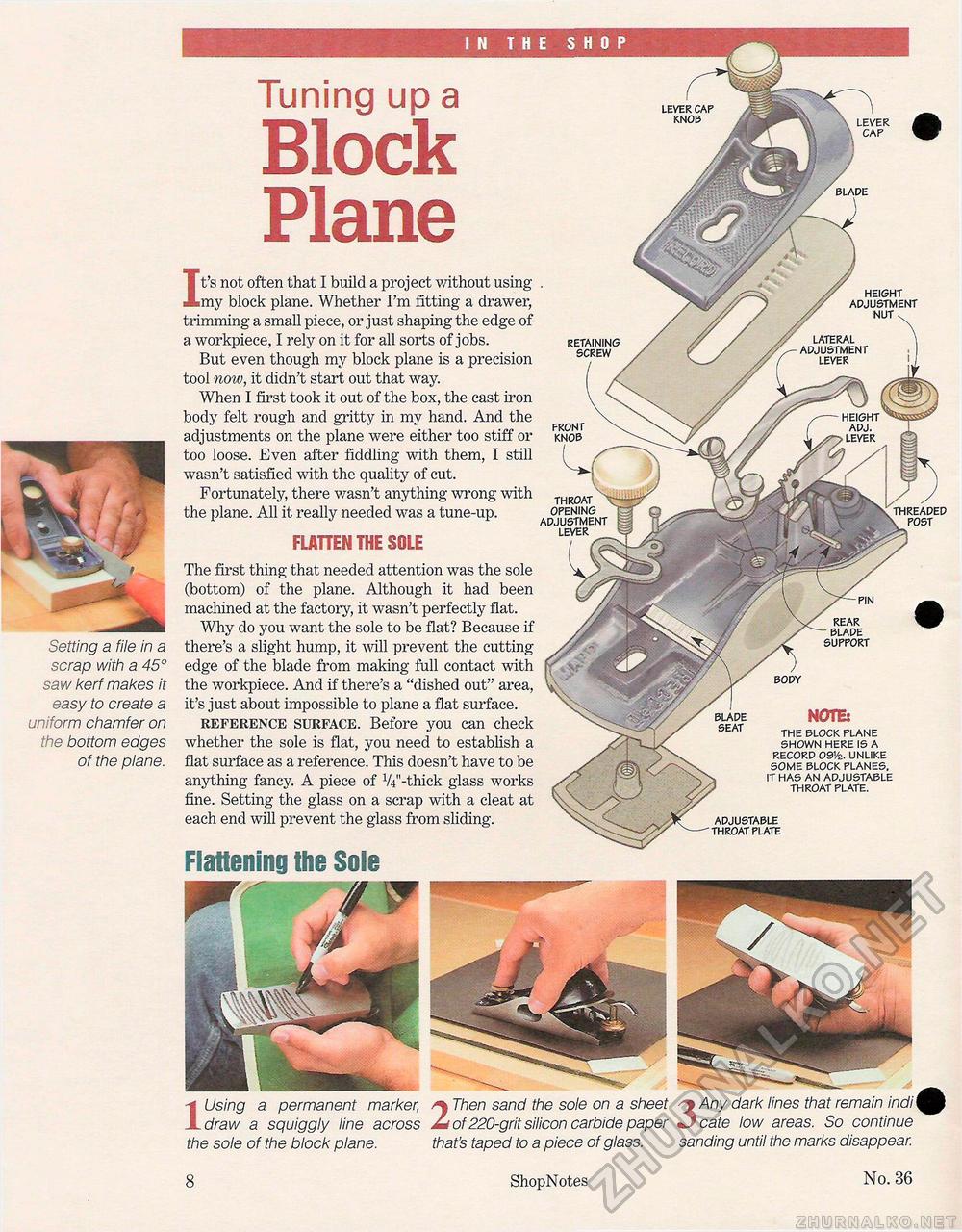

IN THE SHOP Setting a file in a scrap with a 45° saw kerf makes it easy to create a uniform chamfer on the bottom edges of the plane. Tuning up a Block PlaneIt's not often that I build a project without using my block plane. Whether I'm fitting a drawer, trimming a small piece, or just shaping the edge of a workpiece, I rely on it for all sorts of jobs. But even though my block plane is a precision tool noiv, it didn't start out that way. When I first took it out of the box, the cast iron body felt rough and gritty in my hand. And the adjustments on the plane were either too stiff or too loose. Even after fiddling with them, I still wasn't satisfied with the quality of cut. Fortunately, there wasn't anything wrong with the plane. All it really needed was a tune-up. FLATTEN THE SOLE The first thing that needed attention was the sole (bottom) of the plane. Although it had been machined at the factory, it wasn't perfectly flat. Why do you want the sole to be flat? Because if there's a slight hump, it will prevent the cutting edge of the blade from making full contact with the workpiece. And if there's a "dished out" area, it's just about impossible to plane a flat surface. reference surface. Before you can check whether the sole is flat, you need to establish a flat surface as a reference. This doesn't have to be anything fancy. A piece of V4"-thick glass works fine. Setting the glass on a scrap with a cleat at each end will prevent the glass from sliding. Flattening the Sole NOTEs the block plane shown here is a record 09V2. unlike some block planes, it has an adjustable throat plate. adjustable 'throat plate f Using a permanent the sole of the block plane. marker Then sand the sole on a sheet Any dark lines that remain indi\ draw a squiggly line across Ai of220-grit silicon carbide paper cate low areas. So continue that's taped to a piece of glass. sanding until the marks disappear. 8 ShopNotes No. 36 |