40 - Vacuum Clamping System, страница 12

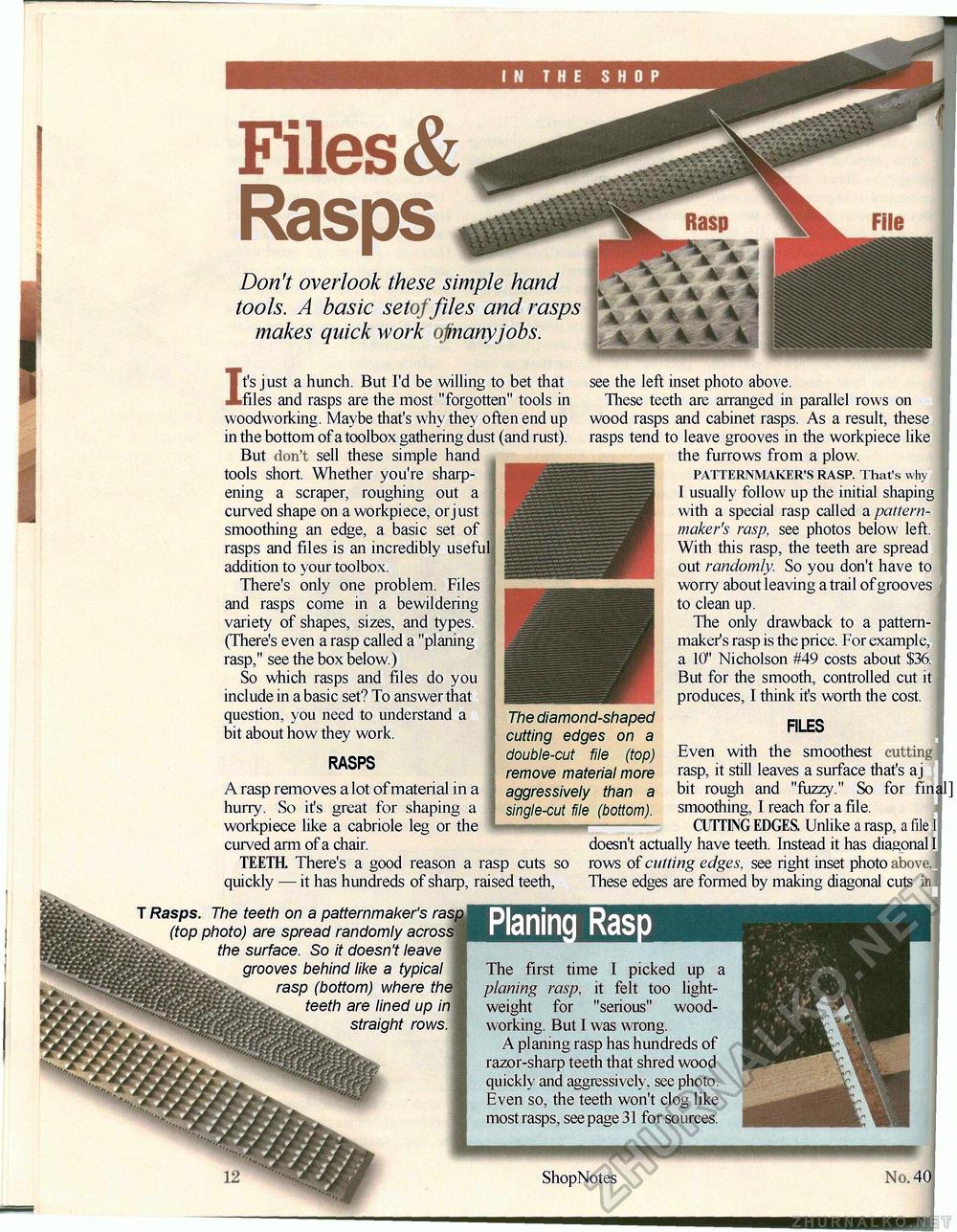

IN THE SHOP Files & RaspsDon't overlook these simple hand tools. A basic setof files and rasps makes quick work ojmanyjobs. It's just a hunch. But I'd be willing to bet that files and rasps are the most "forgotten" tools in woodworking. Maybe that's why they often end up in the bottom of a toolbox gathering dust (and rust). But don't sell these simple hand tools short. Whether you're sharpening a scraper, roughing out a curved shape on a workpiece, or just smoothing an edge, a basic set of rasps and files is an incredibly useful addition to your toolbox. There's only one problem. Files and rasps come in a bewildering variety of shapes, sizes, and types. (There's even a rasp called a "planing rasp," see the box below.) So which rasps and files do you include in a basic set? To answer that question, you need to understand a bit about how they work. 4 see the left inset photo above. These teeth are arranged in parallel rows on wood rasps and cabinet rasps. As a result, these rasps tend to leave grooves in the workpiece like the furrows from a plow. PATTERNMAKER'S RASP. That's why I usually follow up the initial shaping with a special rasp called a patternmaker's rasp, see photos below left. With this rasp, the teeth are spread out randomly. So you don't have to worry about leaving a trail of grooves to clean up. The only drawback to a patternmaker's rasp is the price. For example, a 10" Nicholson #49 costs about $36. But for the smooth, controlled cut it produces, I think it's worth the cost. RASPS A rasp removes a lot of material in a hurry. So it's great for shaping a workpiece like a cabriole leg or the curved arm of a chair. TEETH. There's a good reason a rasp cuts so quickly — it has hundreds of sharp, raised teeth, T Rasps. The teeth on a patternmaker's rasp (top photo) are spread randomly across the surface. So it doesn't leave grooves behind like a typical rasp (bottom) where the teeth are lined up in straight rows. The diamond-shaped cutting edges on a double-cut file (top) remove material more aggressively than a single-cut file (bottom). FILES with the smoothest cutting Even rasp, it still leaves a surface that's a j bit rough and "fuzzy." So for final] smoothing, I reach for a file. CUTTING EDGES. Unlike a rasp, a file I doesn't actually have teeth. Instead it has diagonal I rows of cutting edges, see right inset photo above. These edges are formed by making diagonal cuts in I The first time I picked up a planing rasp, it felt too lightweight for "serious" woodworking. But I was wrong. A planing rasp has hundreds of razor-sharp teeth that shred wood quickly and aggressively, see photo. Even so, the teeth won't clog like most rasps, see page 31 for sources. ShopNotes |