40 - Vacuum Clamping System, страница 13

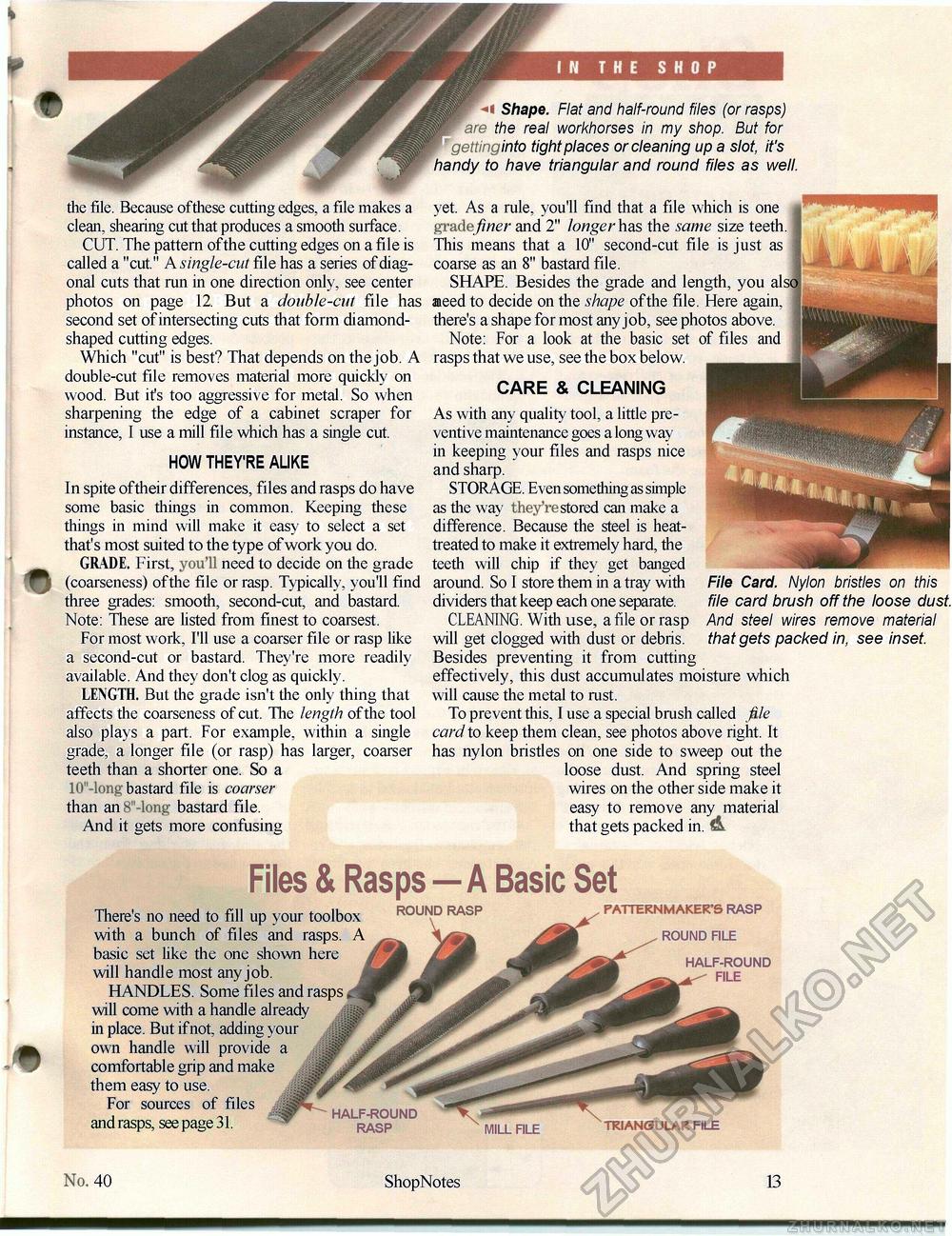

the file. Because ofthese cutting edges, a file makes a clean, shearing cut that produces a smooth surface. CUT. The pattern ofthe cutting edges on a file is called a "cut." A single-cut file has a series of diagonal cuts that run in one direction only, see center photos on page 12. But a double-cut file has second set of intersecting cuts that form diamond-shaped cutting edges. Which "cut" is best? That depends on the job. A double-cut file removes material more quickly on wood. But it's too aggressive for metal. So when sharpening the edge of a cabinet scraper for instance, I use a mill file which has a single cut. HOW THEY'RE ALIKE In spite of their differences, files and rasps do have some basic things in common. Keeping these things in mind will make it easy to select a set that's most suited to the type of work you do. GRADE. First, you'll need to decide on the grade (coarseness) ofthe file or rasp. Typically, you'll find three grades: smooth, second-cut, and bastard. Note: These are listed from finest to coarsest. For most work, I'll use a coarser file or rasp like a second-cut or bastard. They're more readily available. And they don't clog as quickly. LENGTH. But the grade isn't the only thing that affects the coarseness of cut. The length ofthe tool also plays a part. For example, within a single grade, a longer file (or rasp) has larger, coarser teeth than a shorter one. So a 10"-long bastard file is coarser than an 8"-long bastard file. And it gets more confusing IN THE SHOP * Shape. Flat and half-round files (or rasps) are the real workhorses in my shop. But for getting into tight places or cleaning up a slot, it's handy to have triangular and round files as well. yet. As a rule, you'll find that a file which is one gradefiner and 2" longer has the same size teeth. This means that a 10" second-cut file is just as coarse as an 8" bastard file. SHAPE. Besides the grade and length, you need to decide on the shape ofthe file. Here again, there's a shape for most any job, see photos above. Note: For a look at the basic set of files and rasps that we use, see the box below. CARE & CLEANING As with any quality tool, a little preventive maintenance goes a long way in keeping your files and rasps nice and sharp. STORAGE. Even something as simple as the way they're stored can make a difference. Because the steel is heat-treated to make it extremely hard, the teeth will chip if they get banged around. So I store them in a tray with dividers that keep each one separate. CLEANING. With use, a file or rasp will get clogged with dust or debris. Besides preventing it from cutting effectively, this dust accumulates moisture which will cause the metal to rust. To prevent this, I use a special brush called file card to keep them clean, see photos above right. It has nylon bristles on one side to sweep out the loose dust. And spring steel wires on the other side make it easy to remove any material that gets packed in. & File Card. Nylon bristles on this file card brush off the loose dust. And steel wires remove material that gets packed in, see inset. Files & Rasps—A Basic Set There's no need to fill up your toolbox with a bunch of files and rasps. A basic set like the one shown here will handle most any job. HANDLES. Some files and rasps will come with a handle already in place. But if not, adding your own handle will provide a comfortable grip and make them easy to use. For sources of files and rasps, see page 31. round rasp patternmaker's rasp round file half-round file half-round rasp mill file TRIANGULAR FILE 40 ShopNotes 13 |