65 - Our Best Bench Yet, страница 19

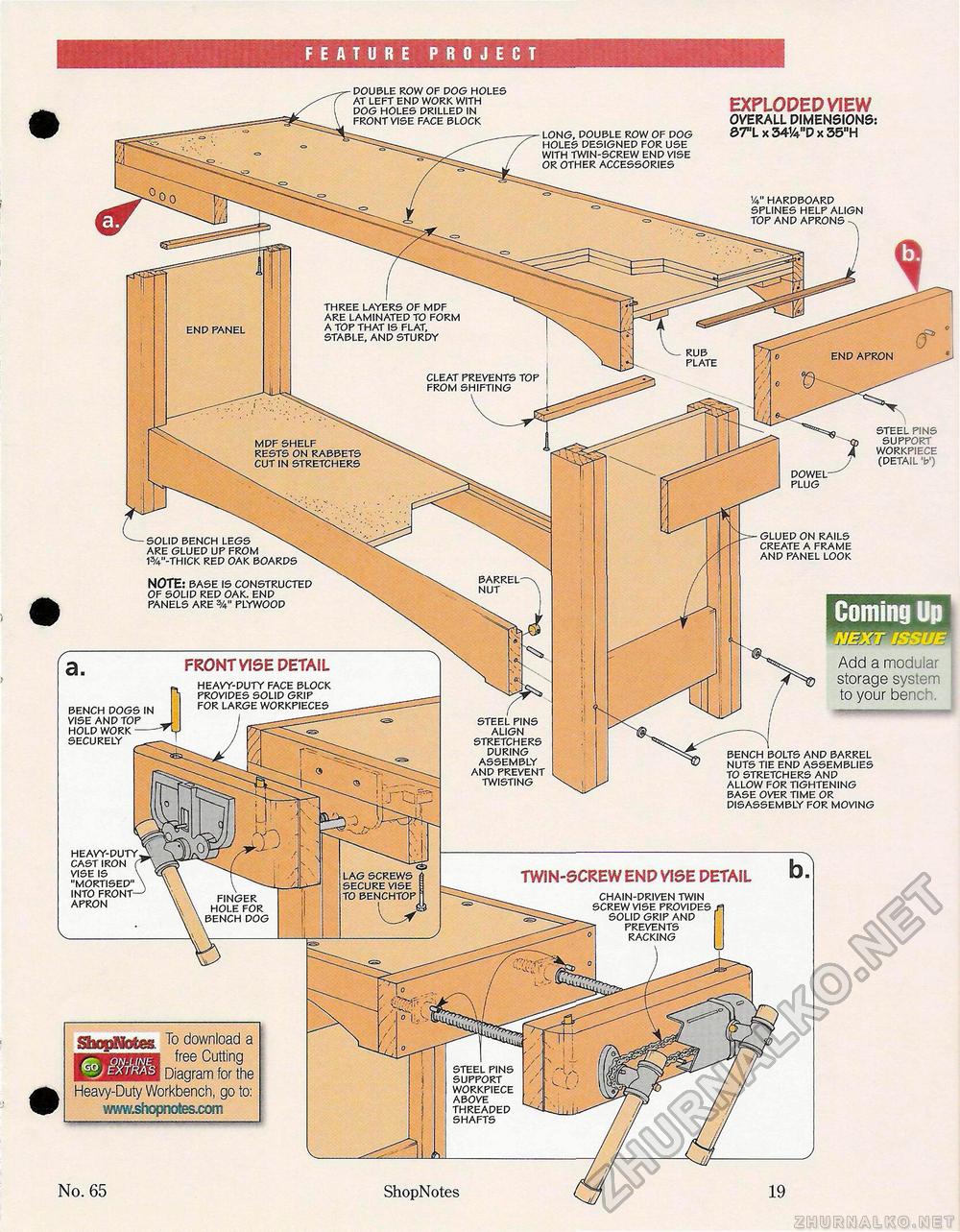

FEATURE PROJECT i ) > lag screws secure vise to benchtop finger hole for bench dog three layers of mdf are laminated to form a top that is flat, stable, and sturdy end panel end apron mdf shelf rests on rabbets cut in stretchers dowel- ShopMolea HUH To download a free Cutting Diagram for the Heavy-Duty Workbench, go to: ww^hopnoles,com ■solid bench legs are glued up from w-thick red oak boards glued on rails create a frame and panel look steel pins align stretchers during assembly and prevent twisting double row of dog holes at left end work with dog holes drilled in front vise face block long, double row of dog holes designed for use with twin-screw end vise or other accessories EXPLODED VIEW OVERALL DIMENSIONS: 8>Tl x 3414"D x 35"H va" hardboard splines help align top and aprons NOTE: base is constructed of solid red oak. end panels are 3/4" plywood FRONT VISE DETAIL heavy-duty face block provides solid grip for large workpieces cleat prevents top from shifting plug steel PINS SUPPORT WORKPIECE (DETAIL 'b') bench dogs in vise and top hold work- securely heavy-duty, cast iron vise is "mortised" into front-apron TWIN-SCREW ENP VISE DETAIL Add a modular storage system to your bench. bench bolts and barrel nuts tie end assemblies to stretchers and allow for tightening base overtime or disassembly for moving rub plate steel pins support workpiece above threaded shafts chain-driven twin screw vise provides solid grip and =1 prevents ' racking No. 65 ShopNotes 19 |