65 - Our Best Bench Yet, страница 24

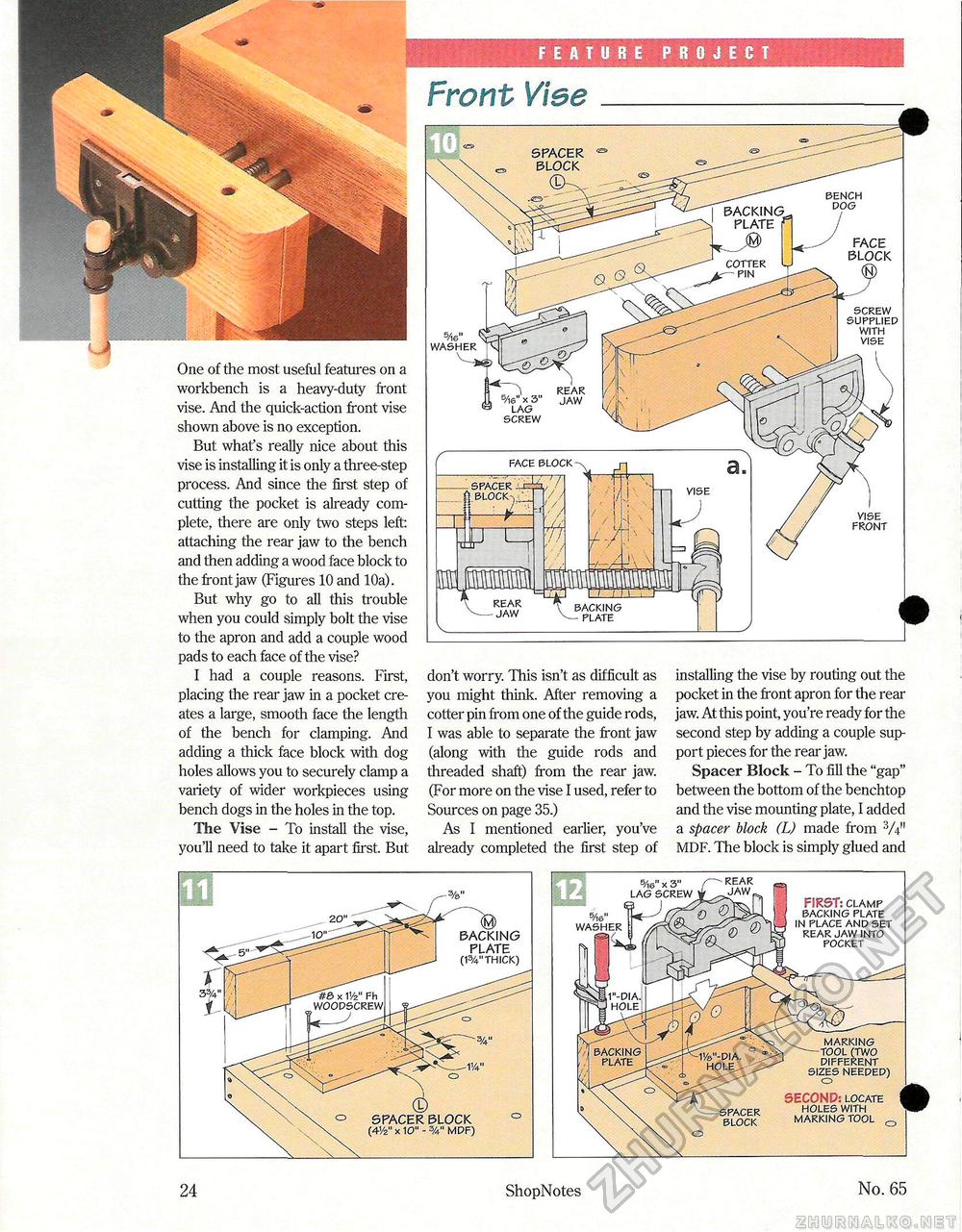

FEATURE PROJECT Front Vise One of the most useful features on a workbench is a heavy-duty front vise. And the quick-action front vise shown above is no exception. But what's really nice about this vise is installing it is only a three-step process. And since the first step of cutting the pocket is already complete, there are only two steps left: attaching the rear jaw to the bench and then adding a wood face block to the front jaw (Figures 10 and 10a). But why go to all this trouble when you could simply bolt the vise to the apron and add a couple wood pads to each face of the vise? I had a couple reasons. First, placing the rear jaw in a pocket creates a large, smooth face the length of the bench for clamping. And adding a thick face block with dog holes allows you to securely clamp a variety of wider workpieces using bench dogs in the holes in the top. The Vise - To install the vise, you'll need to take it apart first. But VISE FRONT don't worry. This isn't as difficult as you might think. After removing a cotter pin from one of the guide rods, I was able to separate the front jaw (along with the guide rods and threaded shaft) from the rear jaw. (For more on the vise I used, refer to Sources on page 35.) As I mentioned earlier, you've already completed the first step of installing the vise by routing out the pocket in the front apron for the rear jaw. At this point, you're ready for the second step by adding a couple support pieces for the rear jaw. Spacer Block - To fill the "gap" between the bottom of the bench top and the vise mounting plate, I added a spacer block (L) made from -VV1 MDF. The block is simply glued and \ a. VISE 5/is" WASHER SCREW BENCH DOG FACE BLOCK SCREW SUPPLIED WITH VISE I N<3 PLATE (1%" THICK) BLOCK (4</2" x 10" - %" MDF) FIRST: CLAMP BACKING PLATE IN PLACE AND SET REAR JAW INTO POCKET SPACER BLOCK MARKING TOOL (TWO DIFFERENT SIZES NEEDED) O SECONDS LOCATE HOLES WITH MARKING TOOL 0 24 ShopNotes No. 65 |