65 - Our Best Bench Yet, страница 28

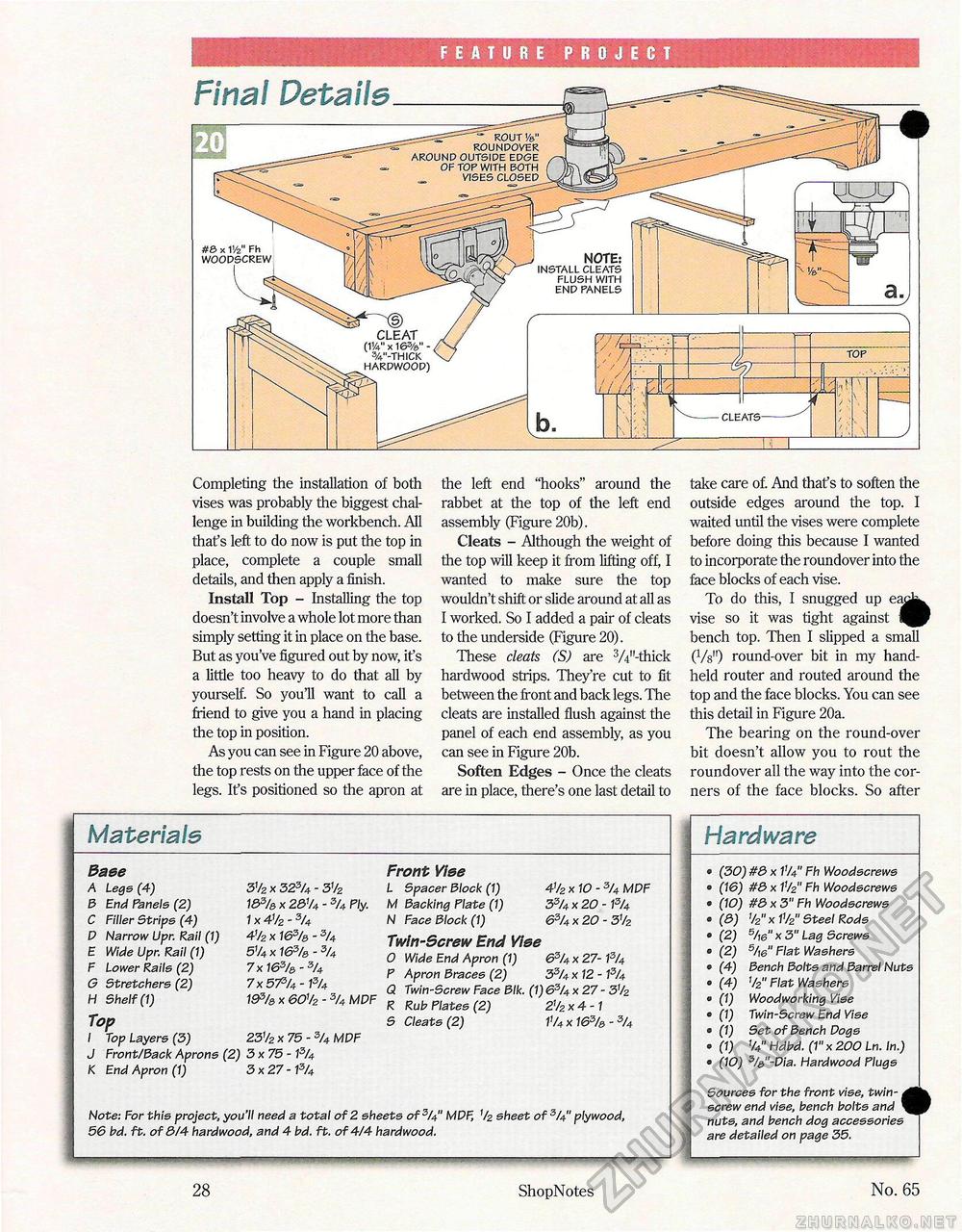

FEATURE PROJECT — ~ ROUT V&" ROUNDOVER AROUND OUTSIDE EDGE OF TOP WITH BOTH VISES CLOSED #S x V/z" Fh WOODSCREW NOTE: INSTALL CLEATS FLUSH WITH END PANELS CLEAT (W X 16%" - %"-THICK HARDWOOD) Completing the installation of both vises was probably the biggest challenge in building the workbench. All that's left to do now is put the top in place, complete a couple small details, and then apply a finish. Install Top - Installing the top doesn't involve a whole lot more than simply setting it in place on the base. But as you've figured out by now, it's a little too heavy to do that all by yourself. So you'll want to call a friend to give you a hand in placing the top in position. As you can see in Figure 20 above, the top rests on the upper face of the legs. It's positioned so the apron at the left end "hooks" around the rabbet at the top of the left end assembly (Figure 20b). Cleats - Although the weight of the top will keep it from lifting off, I wanted to make sure the top wouldn't shift or slide around at all as I worked. So I added a pair of cleats to the underside (Figure 20). These cleats (S) are S/V'-thick hardwood strips. They're cut to fit between the front and back legs. The cleats are installed flush against the panel of each end assembly, as you can see in Figure 20b. Soften Edges - Once the cleats are in place, there's one last detail to take care of. And that's to soften the outside edges around the top. I waited until the vises were complete before doing this because I wanted to incorporate the roundover into the face blocks of each vise. To do this, I snugged up ead^ vise so it was tight against bench top. Then I slipped a small (Vs") round-over bit in my handheld router and routed around the top and the face blocks. You can see this detail in Figure 20a. The bearing on the round-over bit doesn't allow you to rout the roundover all the way into the corners of the face blocks. So after Materials Base A Legs (4) B End Panels (2) C Filler Strips (4) D Narrow Upr. Rail (1) E Wide Upr. Rail (1) F Lower Rails (2) G Stretchers (2) H Shelf (1) Top I Top Layers (3) J Front/Back Aprons (2) K End Apron (1) 3% x 323/4 - 31/z 133/& x 23% - 3/4 Ply. 1 x 4V2 - 3U 4V2 x 163/& - 3U 5%x163/3-3/4 7 x 163/& - 3U 7 x ST^U - 13U l&i/s x 601/2 - 3U MDF 231/2 x 75 - 3U MDF 3x75-13U 3x27-13U Front Vise L Spacer Block (1) 41/2 x 10 - 3/4 MDF M Backing Plate (1) 33U x 20 - 13U N Face Block (1) 63U x 20 - 31/2 Twin-Screw End Vise O Wide End Apron (1) 63U x 27-1% P Apron Braces (2) 33/4x12-13/4 Q Twin-Screw Face Blk. (1) 63/4 x 27 - 31/2 R Rub Plates (2) 2%x4-1 S Cleats (2) V/4 x 163/& - 3U Note: For this project, you'll need a total of 2 sheets of3/4" MDF, 1/2 sheet of 3/4" plywood, 56 bd. ft. of 3/4 hardwood, and 4 bd. ft. of 414 hardwood. —:— - Hardware (30) #3 x 1'/4" Fh Woodscrews (16) #3 x 11/2" Fh Woodscrews (10) #3 x 3" Fh Woodscrews (3) 1/2" x 11/2" Steel Rods (2) 5he" x 3" Lag Screws (2) %6" Flat Washers (4) Bench Bolts and Barrel Nuts (4) V2" Flat Washers (1) Woodworking Vise (1) Twin-Screw End Vise (1) Set of Bench Dogs (1) %n Hdbd. (1" x 200 Ln. In.) (10) 3/&"-Dia. Hardwood Plugs Sources for the front vise, twin-screw end vise, bench bolts and nuts, and bench dog accessories are detailed on page 35. 28 ShopNotes No. 65 |